Car seat simulative vibration experiment table

A technology of car seats and test benches, which is applied in the field of mechanical vibration tables, can solve problems such as high cost and difficult frequency adjustment, and achieve the effect of improving power requirements and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

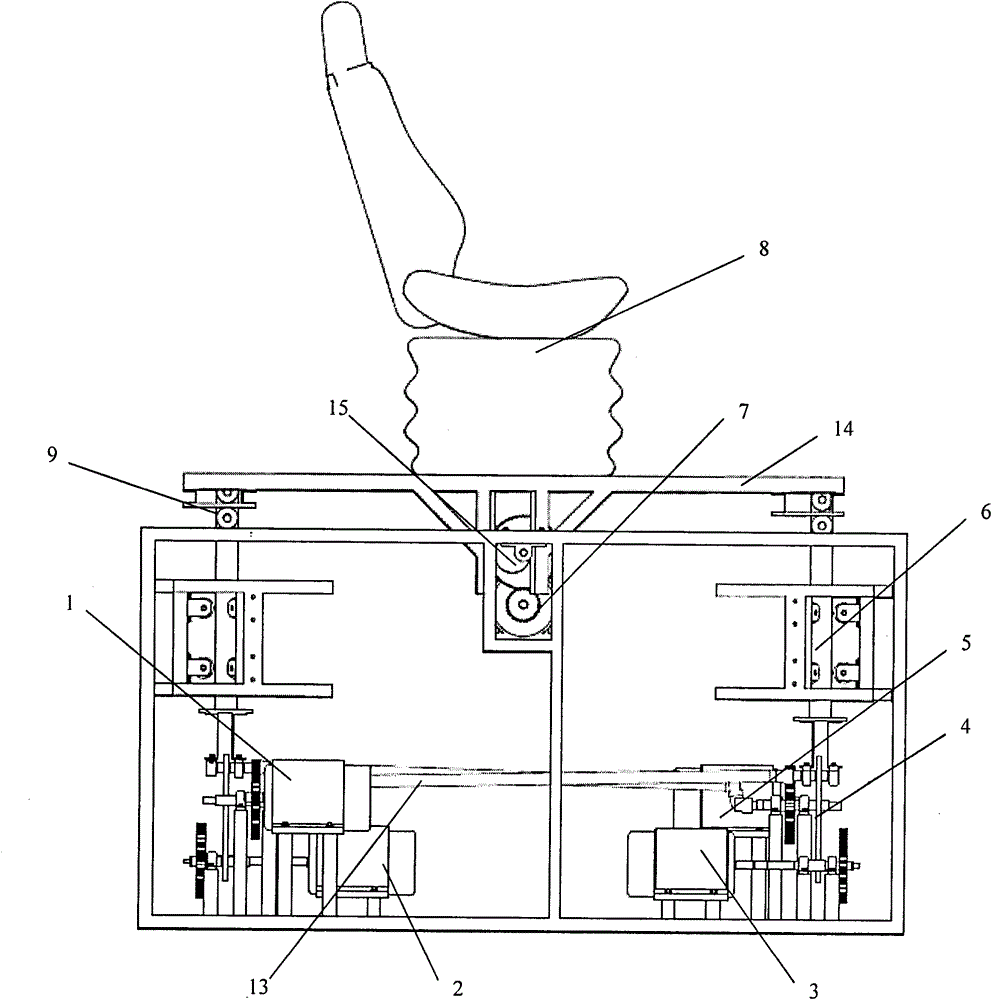

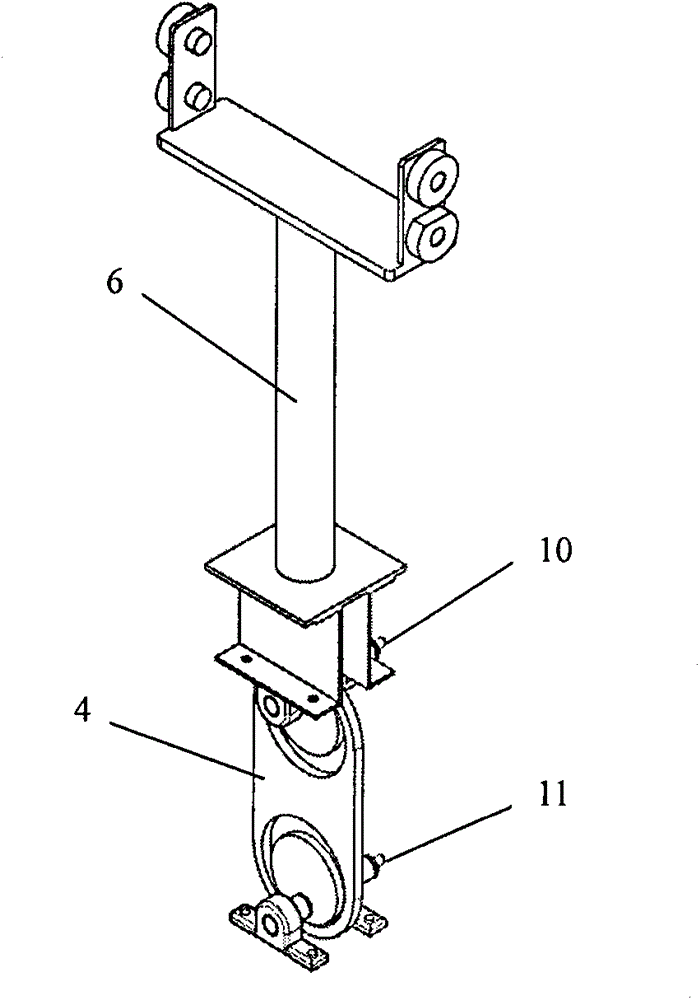

[0009] A car seat simulated vibration test bench, consisting of a first servo motor (1), a first constant speed motor (2), a second constant speed motor (3), a double-drive crank slider mechanism (4), a second servo Motor (5), vertical guide mechanism (6), horizontal drive motor (7), seat system (8), horizontal guide mechanism (9), second drive shaft (10), first drive shaft (11), long shaft (13), vibration table (14), and eccentric wheel mechanism (15); wherein the first servo motor (1) drives the second drive shaft (10) through the long shaft (13), and the second constant speed motor (3) Driving the first drive shaft (11), the first servo motor (1) and the second constant-speed motor (3) are the two power sources of the double-drive slider crank mechanism (4), and they function as the vertical guide mechanism (6). The vertical excitation motion is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com