Adjustable water-cooling sampling gun device for boiler and sampling method

A sampling gun and water-cooling technology, which is applied in sampling devices, preparation of test samples, etc., can solve the problem that the sampling gun cannot withstand the high temperature of the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

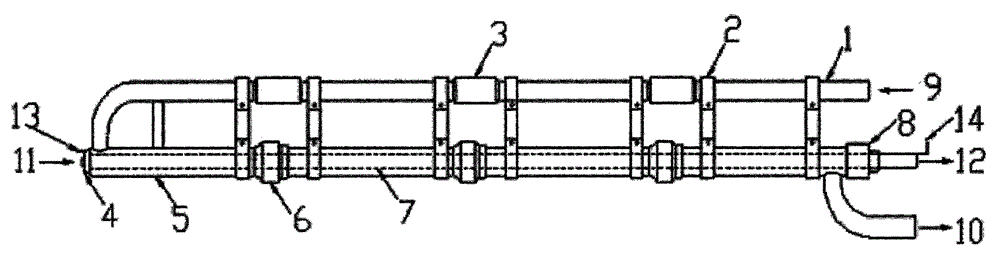

[0008] The invention is a detachable multi-stage water-cooled gun which can operate safely under high-temperature environment. The sampling gun is equipped with a circulating water cooling pipeline, the cooling water inlet pipeline and the cooling water outlet pipeline are connected to each other through a high temperature resistant metal bracket, and the sample sampling tube is sleeved inside the outlet pipeline. Assemble multi-section stainless steel water-cooling components through threaded connection to form a water-cooling gun, and the sealing between each water-cooling component is realized by copper gaskets. Considering the test furnace, on-site installation and transportation conditions, the length of the sampling gun can be composed of water-cooled components of different lengths.

[0009] Be described below in conjunction with accompanying drawing.

[0010] The water-cooled sampling gun mainly includes a sampling pipe and a circulating water-cooling pipeline compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com