Bidirectional stress state stress-strain measurement device and method for thin-walled tube

A technology of stress-strain and bi-directional stress, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem that the stress-strain information of thin-walled pipes cannot be obtained, and the stress path of thin-walled pipes cannot be accurately controlled and the strain information is accurate. Measurement and other issues, to achieve the effect of simple structure, large strain measurement range, and expand the range of stress variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

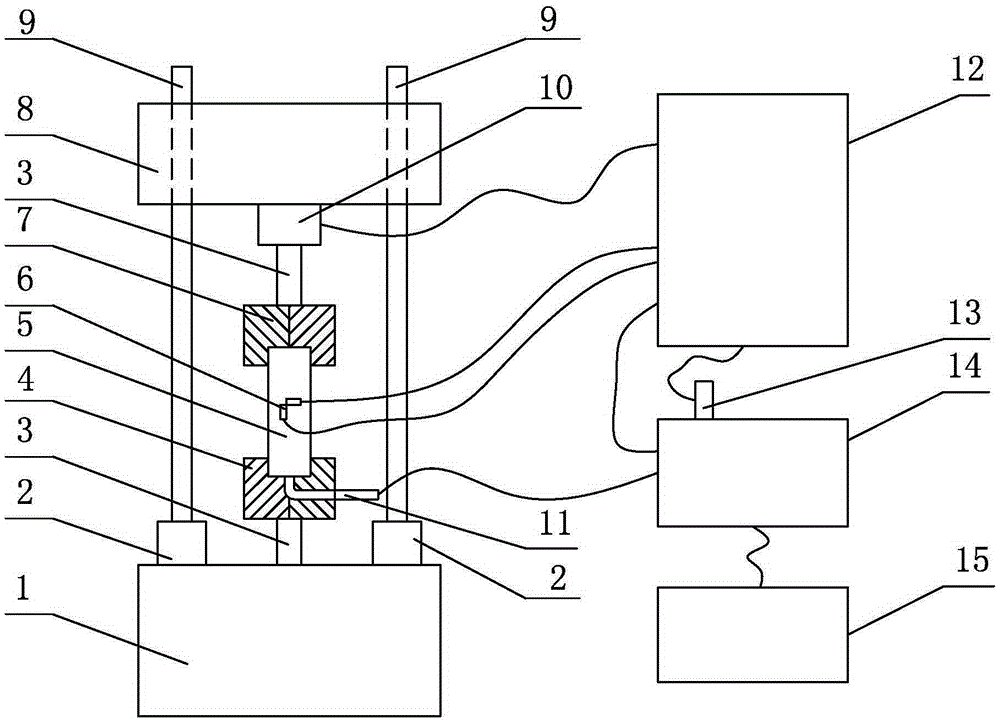

[0026] Specific implementation mode one: combine figure 1 , Figure 3-Figure 4 Explain that a thin-walled pipe bidirectional stress state stress-strain measurement device of this embodiment includes a base 1, a strain gauge 6, a movable beam 8, a pump station 15, an oil pressure booster 14, a force sensor 10, and a pressure sensor 13 , control system 12, two upper chucks 7, two lower chucks 4, two screw pairs 9 and two motors 2;

[0027]Two motors 2 are installed side by side on the base 1, and the axes of the two motors 2 are arranged vertically. The output end of each motor 2 is fixed with a lead screw pair 9, and the movable beam 8 is horizontally installed on the two lead screw pairs. 9 and fixedly connected with the nuts of the two lead screw pairs 9, the force sensor 10 is installed on the lower surface of the movable beam 8, the force sensor 10 is connected with the two upper chucks 7 through the connecting rod 3, and the base 1 is connected through the connecting rod ...

specific Embodiment approach 2

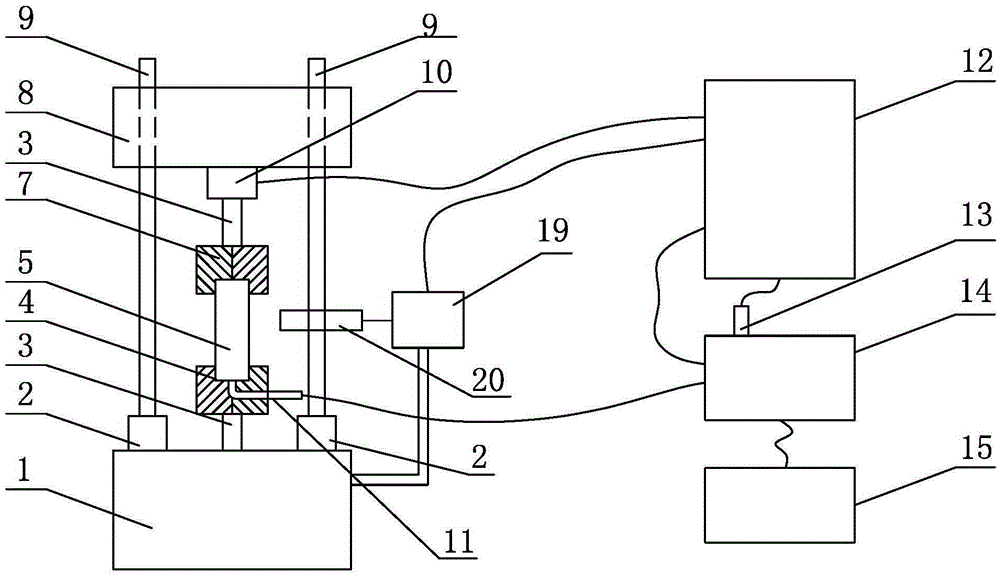

[0030] Specific implementation mode two: combination image 3 and Figure 4 Note that the motor 2 in this embodiment is a servo motor, and the thin-walled tube bidirectional stress state stress-strain measurement device also includes a speckle strain measurement system 19, and the middle area of the outer wall of the thin-walled tube 5 is sprayed with spots required by the speckle strain measurement system The speckle strain measurement system 19 is installed on the base 1, the CCD camera of the speckle strain measurement system 19 is used to collect the strain information of the thin-walled pipe 5, the strain signal output terminal of the speckle strain measurement system 19 is connected to the strain signal of the control system 12 input connection. In this way, the strain measurement is carried out by combining the speckle strain measurement system 19 and the strain gauge 6. When the deformation is small, the strain gauge 6 is used for measurement, and the speckle strain...

specific Embodiment approach 3

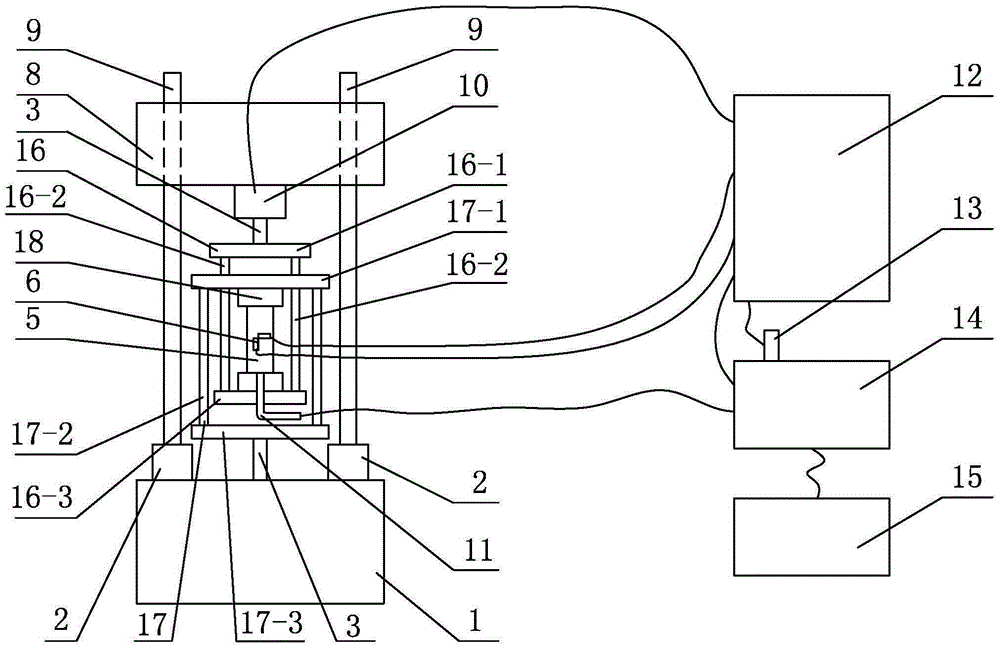

[0031] Specific implementation mode three: combination figure 2 , Figure 5-Figure 6 Explain that a thin-walled pipe bidirectional stress state stress-strain measurement device of this embodiment includes a base 1, a strain gauge 6, a movable beam 8, a pump station 15, an oil pressure booster 14, a force sensor 10, and a pressure sensor 13 , control system 12, movable platform 16, fixed platform 17, two lead screw pairs 9 and two motors 2;

[0032] Two motors 2 are installed side by side on the base 1, and the axes of the two motors 2 are arranged vertically. The output end of each motor 2 is fixed with a lead screw pair 9, and the movable beam 8 is horizontally installed on the two lead screw pairs. 9 and is fixedly connected with the nuts of two leading screw pairs 9, the movable stand 16 includes a movable upper plate 16-1, a movable lower plate 16-3 and two movable pull rods 16-2; the fixed stand 17 includes a fixed upper plate Plate 17-1, fixed lower plate 17-3 and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com