Preparation method of TC18 and TC21 titanium alloy oxidation tint inspection sample blocks

A technology of TC18 and TC21, which is applied in the production field of TC18 and TC21 titanium alloy oxidation color test samples, can solve the problems of buried service life, hidden dangers, no objective and intuitive evaluation standards, etc., and achieve the effect of eliminating judgment errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A kind of manufacture method of TC18 and TC21 titanium alloy oxidation color test block, comprises the following steps:

[0016] 1) Heat a set of 20 oxidation color samples of TC21 and TC18 titanium alloys at 100°C to 1000°C. The specific heating temperature points are: 100°C, 150°C, 200°C, 250°C, 300°C, 350°C, 400°C, 450°C, 500°C, 550°C, 600°C, 650°C, 700°C, 750°C, 800°C, 850°C, 900°C, 950°C, 1000°C, heating and holding time: 2 hours. Heating is carried out in a low-temperature electric furnace below 700°C, and in a high-temperature electric furnace above 700°C; the temperature uniformity of the heating equipment is ±5°C;

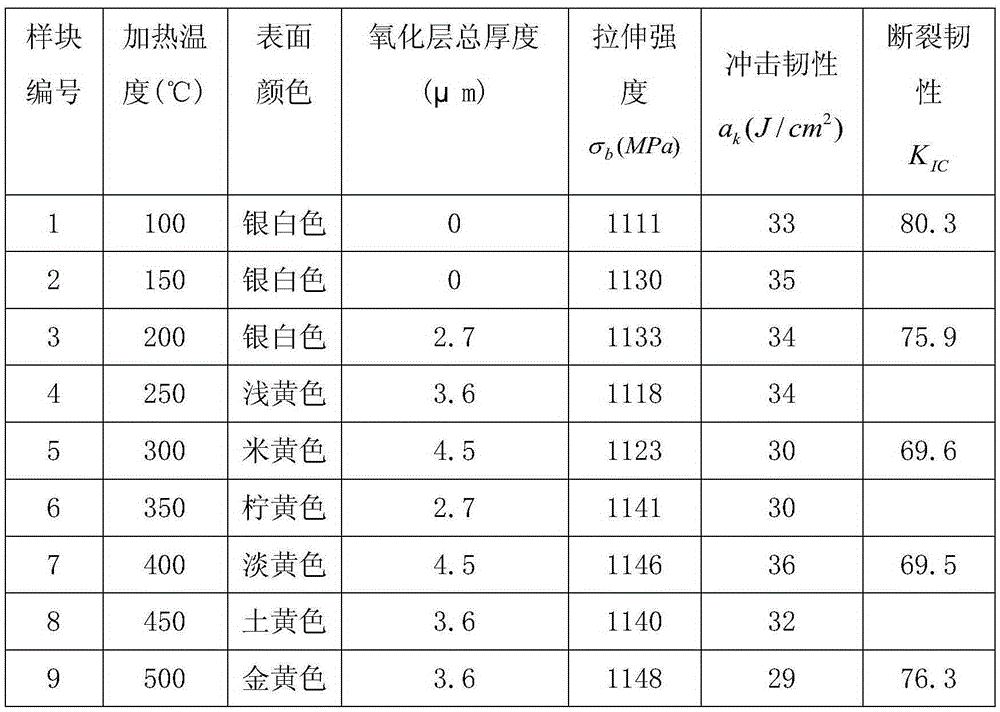

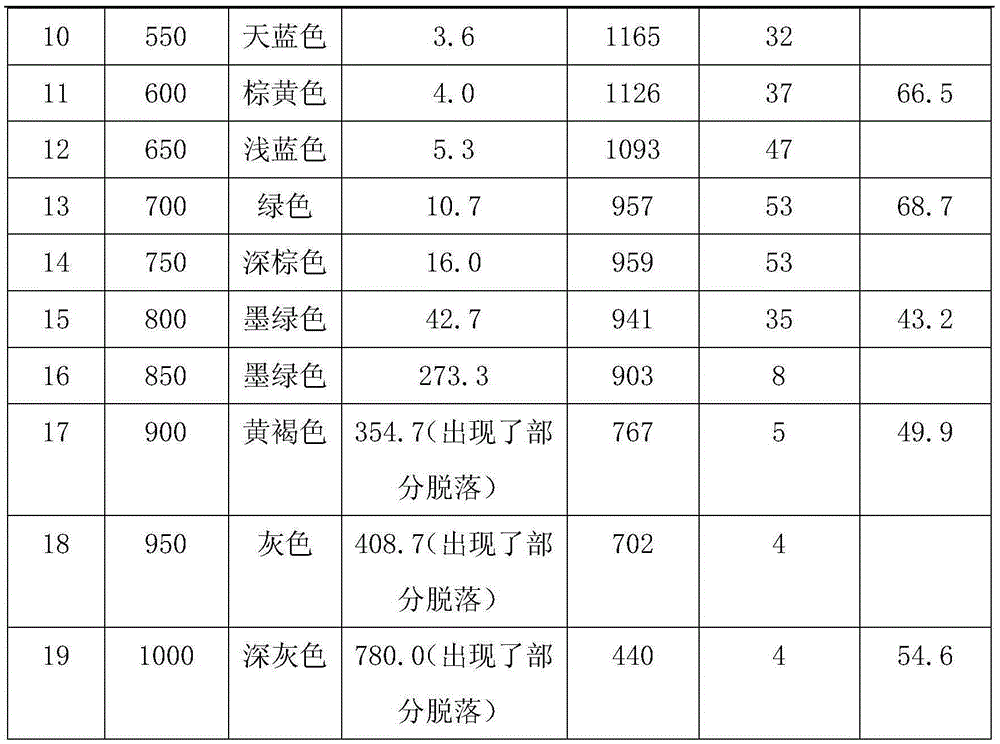

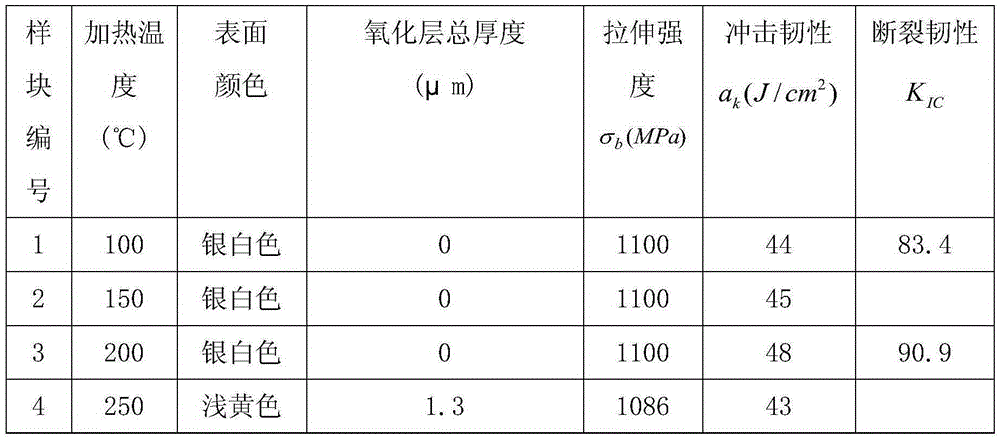

[0017] 2) Test the tensile properties, impact toughness, fracture toughness, oxide layer thickness and metallographic structure of the samples corresponding to the various oxidation colors of TC18 heated at different temperatures. The test results are shown in the table below. The test results are based on The TC18 material standards and technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com