Method for completeness evaluation of nuclear power plant debugging test projects

A technology for test items and integrity, applied in the field of integrity assessment of nuclear power plant commissioning and test items, can solve problems such as difficulty in ensuring the integrity of test items, lack of a list of benchmarking test items, etc., achieve great practical and popular value, and ensure completeness and effective, high coverage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

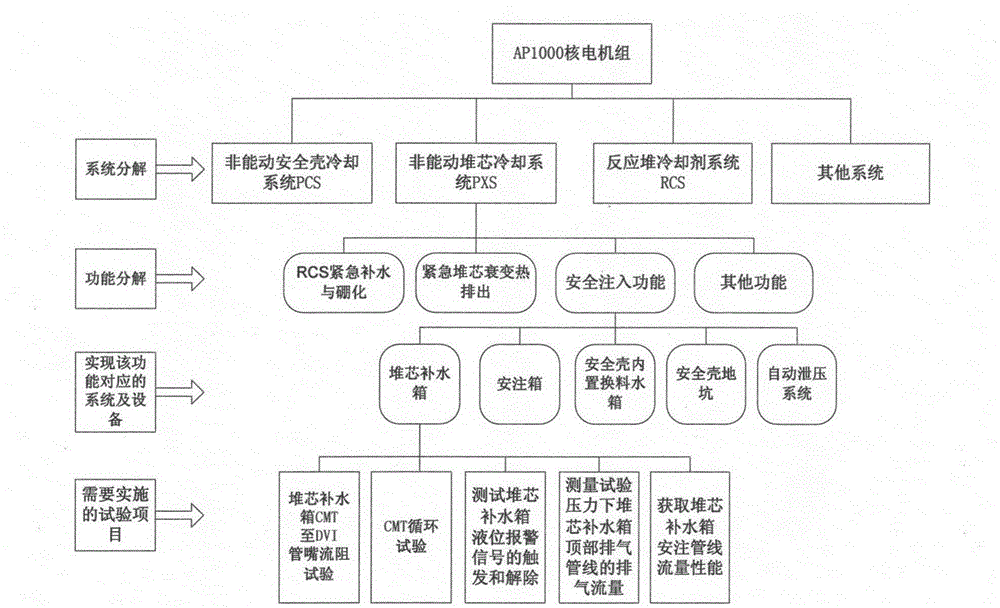

[0025] Taking the AP1000 nuclear power plant passive reactor coolant system as an example to evaluate the integrity of the commissioning test project, the specific steps are as follows:

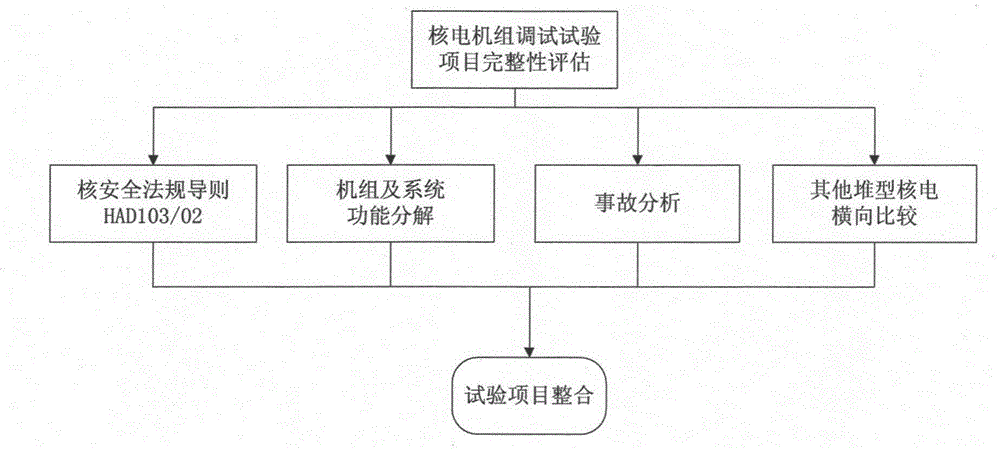

[0026] Step 1: Based on the dimensions of HAD103 / 02 "Nuclear Power Plant Commissioning Procedures" in my country's nuclear safety regulations and guidelines, conduct a completeness assessment of the nuclear power plant commissioning test project.

[0027] For the emergency core cooling system, nuclear safety guidelines emphasize that it can ensure its reliable start after the accident, and inject boron-containing water with a certain pressure and flow rate into the core to meet the requirements of core cooling and reactivity control.

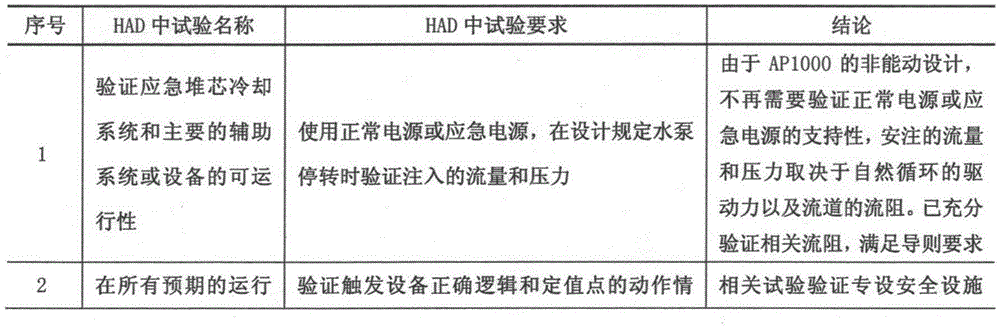

[0028] The comparative analysis of the PXS test of AP1000 and HAD103 / 02 is shown in Table 1. The nuclear safety ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com