Bottom light emitting type OLED display panel

A display panel, light-emitting technology, applied in the direction of organic semiconductor devices, semiconductor devices, electrical components, etc., can solve the problems of limited light-emitting area, large service life loss of light-emitting materials, limited light-emitting efficiency, etc., and achieve the effect of increasing light-emitting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

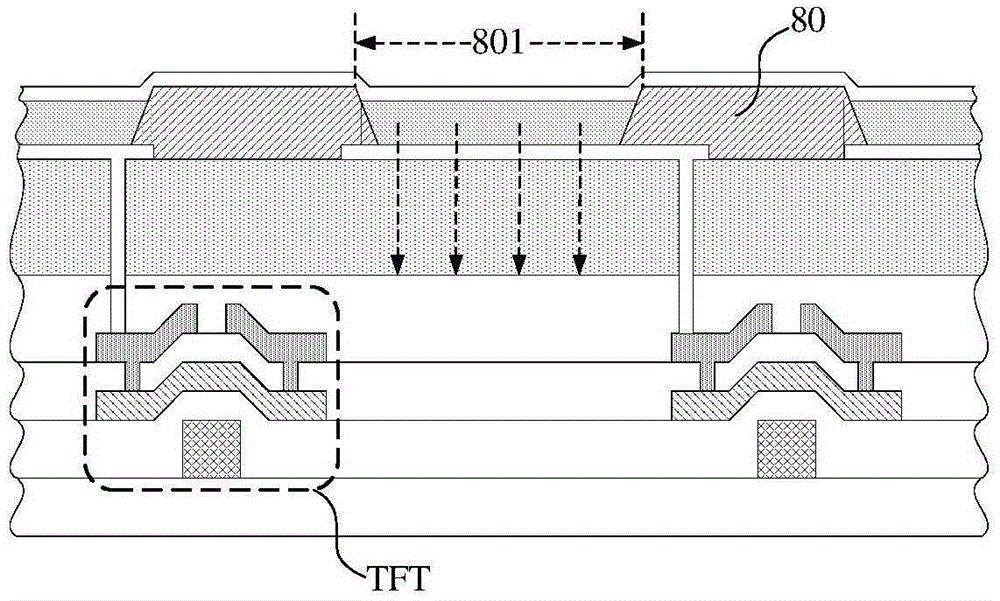

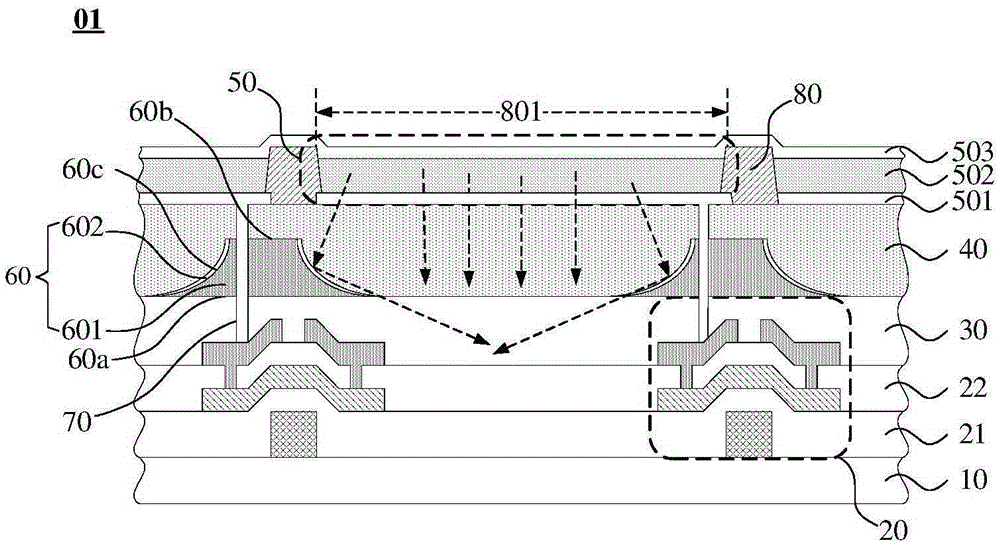

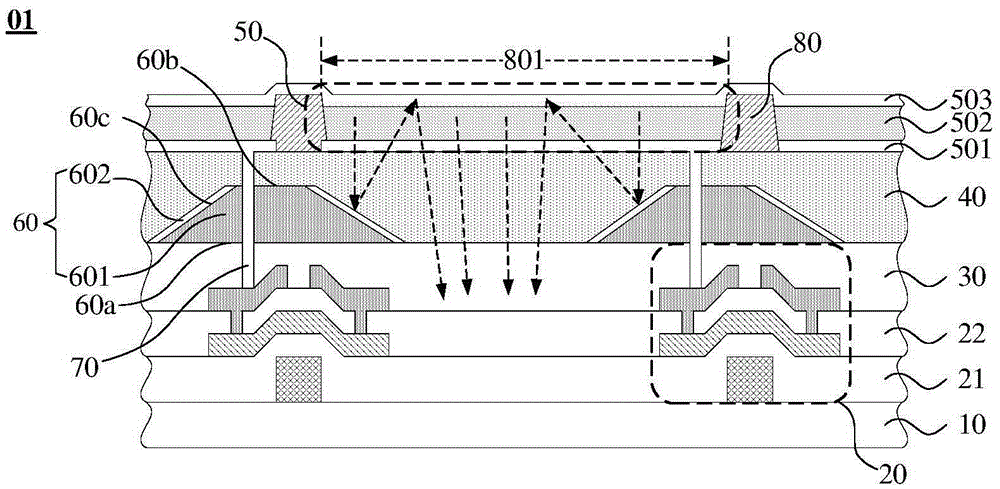

[0052] refer to Figure 2A or Figure 2B As shown, the reflective structure 60 includes a main body 601 and a reflective layer 602; wherein, the main body 601 is composed of a bottom surface 60a and a top surface 60b arranged in parallel, and the side 60c connecting the bottom surface 60a and the top surface 60b is a concave arc surface or a plane; The area of the bottom surface 60a is greater than the area of the top surface 60b, and the bottom surface 60a and the top surface 60b are rectangles whose geometric centers overlap, and as Figure 3A As shown, the adjacent two sides of the rectangle are respectively parallel to the gate line 23 and the data line 24 of the display panel; the reflective layer 602 covers at least one side 60c of the main body portion 601 .

[0053] It should be noted that, first, when the side 60c connecting the bottom surface 60a and the top surface 60b is a concave arc surface, refer to Figure 2A As shown, the shape of the main body portion 6...

Embodiment 2

[0065] refer to Figure 2C As shown, the reflective structure 60 includes a main body 601 and a reflective layer 602; wherein, along the direction perpendicular to the surface of the bottom-emitting OLED display panel 01, the cross-sectional figure of the main body 601 is arc-shaped, and the arc-shaped arc is a semicircle or minor arc; and if Figure 3B As shown, the reflective layer 602 covers at least the arc-shaped half arc surface 60d, and the semi-arc surface 60d takes the direction parallel to the gate line 23 or the data line 24 of the bottom emission type OLED display panel 01 as the dividing line (referred to in the figure as a-a' dotted line indicates).

[0066] It should be noted that, first, when the reflective layer 602 only covers the arc-shaped half-arc surface 60d, and this half-arc surface 60d is parallel to the direction of the gate lines or data lines of the above-mentioned bottom-emission OLED display panel 01 When it is a dividing line, the light irradia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com