Tension control method for cold-rolled strip steel in acid continuous rolling working procedure

A tension control and cold-rolled strip technology, applied in the tension control of cold-rolled strip in the acid continuous rolling process, and the tension control of cold-rolled strip, can solve problems such as loss of support stone and scratches on the surface of strip steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

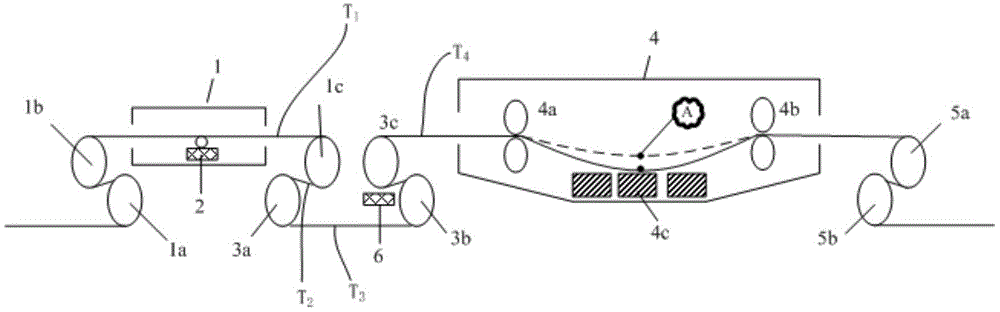

[0049] Such as figure 1 , The continuous acid rolling process unit includes the tension leveler body 1, the first tension roll group 1a, 1b, 1c, the tension leveler tension gauge 2, the second tension roll group 3a, 3b, 3c, the pickling tank body 4, the front and rear clamps Sending rollers 4a, 4b, support stone 4c, third tension roller group 5a, 5b and pickling tank tension gauge 6. Tension tester 2 of the tension leveler is used to measure the strip tension value of the tension leveler section, the pickling tank body 4 is used to pickle the strip steel, and each tension roller group is used for strip production of the tension leveler and the pickling tank tension. The control method of the present invention adjusts the strip steel tension in the tension leveler section so that the strip steel tension in the pickling tank reaches the set requirement, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com