Solid-liquid reaction separation intermittent type ionic liquid production device

An ionic liquid, solid-liquid reaction technology, applied in organic chemistry and other directions, to achieve the effect of solving high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. A solid-liquid reaction separation batch type ionic liquid production device.

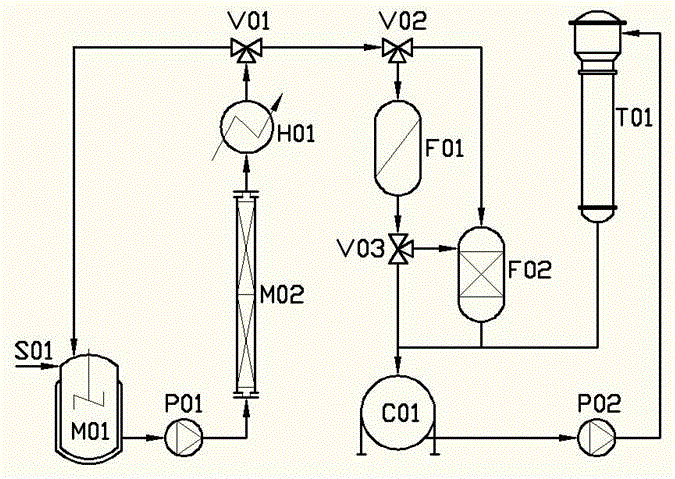

[0022] A solid-liquid reaction separation batch type ionic liquid production device, such as figure 1 As shown, including feed pipeline (S01), stirred reactor (M01), back-mixing circulation pump (P01), static mixer (M02), heat exchanger (H01), reactant material flow direction cut-off valve (V01 ), solid-liquid material flow cut-off valve (V02), solid-liquid separator (F01), liquid-liquid separator (F02), liquid material flow cut-off valve (V03), product tank (C01), product purification circulation pump ( P02), thin film evaporator (T01).

[0023] The stirred reactor (M01) is used as a place for solid-liquid or liquid-liquid mixing, back mixing and reaction.

[0024] The back-mixing circulation pump (P01) is a centrifugal pump, which is used to provide circulation power for solid-liquid or liquid-liquid mixing enhancement.

[0025] The static mixer (M02) is used to strengthen...

Embodiment 2

[0036] Example 2, using a solid-liquid reaction separation batch-type ionic liquid production device of the present invention in combination with Example 1 to produce 1-butyl-3-methylimidazolium dizinc chloride ([C4MIm]Zn2Cl5).

[0037] Raw material A: 1-butyl-3-methylimidazolium chloride salt, 150mol;

[0038] Raw material B: zinc chloride, 305mol;

[0039] Mixed reaction: fully mixed at room temperature, heated up to 100°C for 48 hours, back-mixed circulation pump (P01) with 0.5m 3 / h flow cycle;

[0040] Solid-liquid separation: filter the unreacted zinc chloride solid to obtain 1-butyl-3-methylimidazolium chloride dizinc salt ([C4MIm]Zn2Cl5);

[0041] Production effect: the purity of 1-butyl-3-methylimidazolium dizinc chloride ([C4MIm]Zn2Cl5) is 99.3%.

Embodiment 3

[0042] Example 3, using a solid-liquid reaction separation batch ionic liquid production device of the present invention in combination with Example 1 to produce 1-hexyl-3-methylimidazolium ferric chloride ([C6MIm]FeCl4).

[0043] Raw material A: 1-hexyl-3-methylimidazolium chloride salt, 200mol;

[0044] Raw material B: ferric chloride hexahydrate, 200mol;

[0045] Mixed reaction: step by step mixing, reaction at room temperature for 6 hours, back-mixing circulation pump (P01) with 0.8m 3 / h flow cycle;

[0046] Solid-liquid separation: filter the unreacted solid to obtain two liquid phases;

[0047] Liquid-liquid separation: remove the water phase to obtain the oil phase 1-hexyl-3-methylimidazolium ferric chloride ([C6MIm]FeCl4);

[0048] Product purification: use a thin film evaporator (T01) to distill under reduced pressure to remove residual water in the oil phase;

[0049] Production effect: the purity of 1-hexyl-3-methylimidazolium ferric chloride ([C6MIm]FeCl4) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com