Cracking catalytic device for waste oil and waste plastic

A technology for cracking catalysis and waste plastics, applied in cracking, catalytic cracking, petroleum industry, etc., can solve problems such as increased work costs, complex process flow, secondary pollution, etc., to improve quality, improve heat and mass transfer conditions, reduce coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

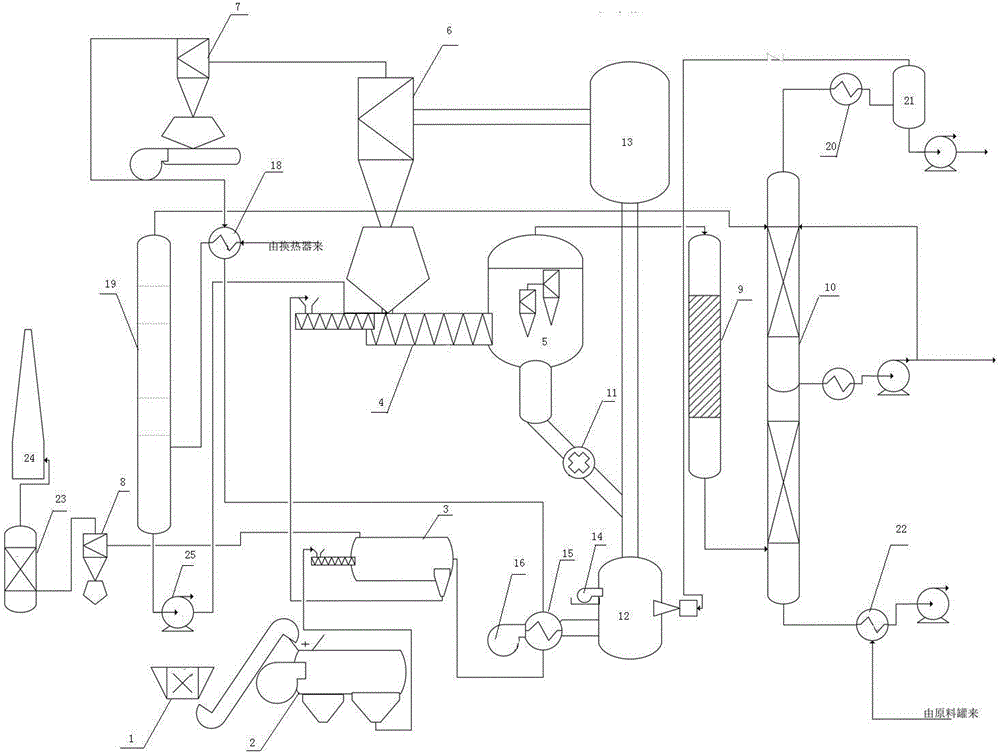

[0015] as the picture shows. A co-cracking catalytic device for waste oil and waste plastics, comprising a pulverizer 1, a wind separator 2, a flue gas preheater 3, a screw propeller 4, a first cyclone separator 5, a second cyclone separator 6, and a third cyclone Separator 7, fourth cyclone separator 8, reactor 9, rectification tower 10, the raw materials enter the first cyclone through pulverizer 1, winnowing machine 2, flue gas preheater 3 and screw propeller 4 in sequence The feed inlet of the separator 5, the solid outlet of the first cyclone separator 5 enter the stockpile 12 through the feeder 11, and the stockpile 12 is connected with the combustion chamber 13 through a riser, and the stockpile 12 is provided with Burner 14, air preheater 15 and fan 16, the outlet of combustion chamber 13 is connected with the feed inlet of second cyclone separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com