Car-washing water wax and preparation method thereof

A technology for car washing water and mass fraction, which is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of large wax debris and diatomite damage to car paint, inability to penetrate car paint, etc. achieve long-lasting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

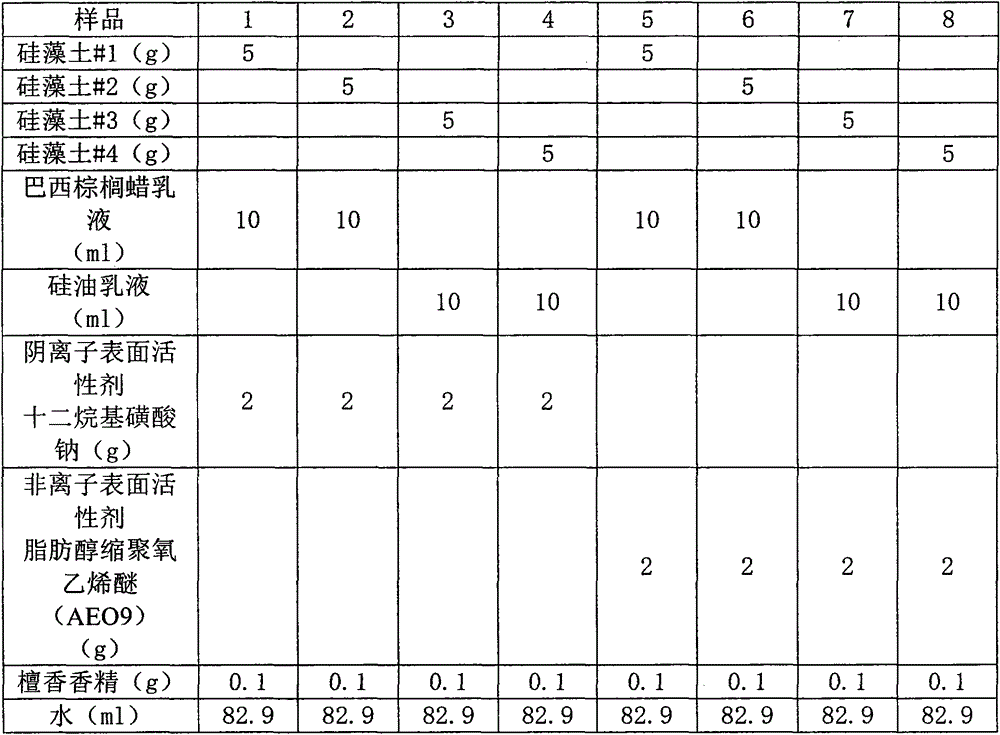

Examples

Embodiment 1

[0014] Dissolve 1g of tetraethoxysilane, 10g of two-terminal silanol polydimethylsilane, 0.5ml of hydrochloric acid, and 1ml of deionized water in 100ml of absolute ethanol, and raise the temperature to 60°C for 36 hours under full stirring to obtain Modified siloxane. Take 2ml of the above reaction solution, add it evenly into 1g of diatomite, stir well, let the solvent evaporate naturally for 2 hours, and obtain siloxane-modified diatomite #1.

Embodiment 2

[0016] Dissolve 1g of methyltrimethoxysilane, 10g of two-terminal silanol polydimethylsilane, 0.5ml of hydrochloric acid, and 1ml of deionized water in 100ml of absolute ethanol, and raise the temperature to 60°C for 36 hours under full stirring. A modified siloxane is obtained. Take 2ml of the above reaction solution, add it evenly into 1g of diatomite, stir well, let the solvent evaporate naturally for 2 hours, and obtain siloxane-modified diatomite #2.

Embodiment 3

[0018] Dissolve 1g of octyltrimethoxysilane, 10g of two-terminal silanol polydimethylsilane, 0.5ml of hydrochloric acid, and 1ml of deionized water in 100ml of absolute ethanol, and raise the temperature to 60°C for 36 hours under full stirring. A modified siloxane is obtained. Take 2ml of the above reaction solution, add it evenly into 1g of diatomite, stir well, let the solvent evaporate naturally for 2 hours, and obtain siloxane-modified diatomite #3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com