A double-sided coated fabric

A technology for coatings and fabrics, applied in fiber processing, textiles, papermaking, synthetic fibers, etc., can solve problems such as easy oxidation, difficulty in large-scale adoption, and expensive rare earth elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

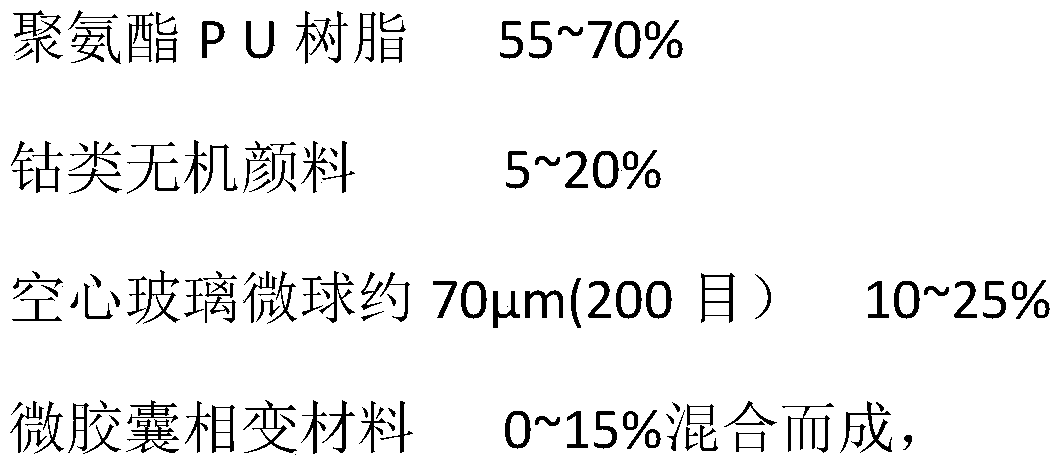

[0036] Embodiment 1: described front coating is by mass percent: polyurethane PU resin 55%

[0037] Cobalt-based inorganic pigments 20%

[0038] Hollow glass microsphere 70μm 25%

[0039] mixed; its reverse coating consists of mass percent

[0040] Polyurethane PU resin 55%

[0041] Cobalt-based inorganic pigments 10%

[0042] Hollow glass microsphere 70μm 20%

[0043] 15% microcapsule phase change material mixed;

[0044] Wherein the thickness of the front paint is 1.5 times of the reverse paint. During processing, the carrier cloth is scraped and coated by the coating machine. The carrier cloth is made of polyethylene with a thickness of 0.20 mm, and the thickness of the scraper is 3.0 mm. Scrape coating at 20 m / min, and then scrape coating on the reverse side after drying, so that the coating on the carrier cloth has a certain thickness and the coating surface is uniform. In this case, a thinner blade is used for rapid multiple strokes due to the thinner substrate. ...

Embodiment 2

[0046] Embodiment 2: described front coating is by mass percent: polyurethane PU resin 70%

[0047] Cobalt-based inorganic pigments 10%

[0048] Hollow glass microsphere 70μm 20%

[0049] mixed; its reverse coating consists of mass percent

[0050] Polyurethane PU resin 70%

[0051] Cobalt-based inorganic pigments 5%

[0052] Hollow glass microsphere 70μm 10%

[0053] 15% microcapsule phase change material mixed,

[0054]Wherein the thickness of the front paint is 1.5 times of the reverse paint. During processing, the carrier cloth is scraped and coated by the coating machine. The carrier cloth is made of polyethylene, polypropylene, polystyrene, ABS, nylon, polycarbonate, nylon 6, and nylon 66 with a thickness of 0.20 mm plus or minus 0.2 mm. , any material of polyester, the thickness of the scraper is 1.5mm~3.0mm, the paint is heated to 150~170 degrees when scraping, the scraping speed is 15~20 m / min for scraping, and the reverse side is applied after drying. Scratch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com