Turbocharger structure capable of achieving single-stage supercharging and two-stage supercharging

A technology of turbochargers and turbines, which is applied to machines/engines, parts of pumping devices for elastic fluids, liquid fuel engines, etc., can solve the problems of single-stage supercharging and occupying space, and achieve reduction The effect of structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

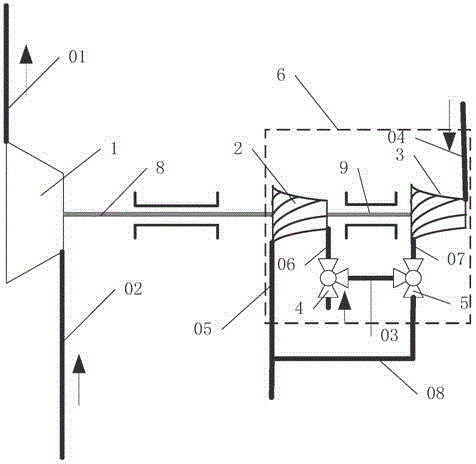

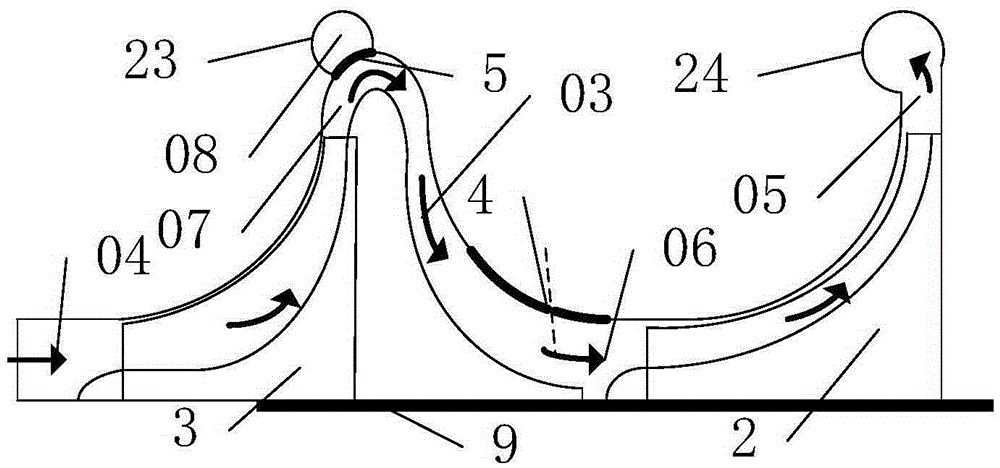

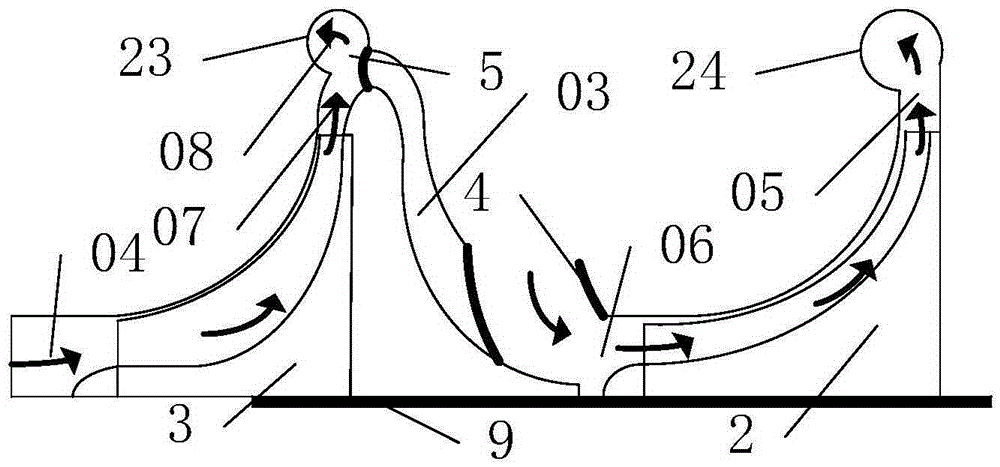

[0014] combine Figure 1~3 , The supercharger of the present invention includes: a turbine 1, a compressor 6 and a shaft A segment 8.

[0015] In the present invention, the structure of the compressor is improved on the basis of the original compressor. The structure of the compressor 6 includes: inlet air passage I04, impeller A3, outlet air passage I07, switching control valve I5, communication air passage I03 , Connecting gas path Ⅱ08, switching control valve Ⅱ4, inlet gas path Ⅱ06, impeller B2, connecting gas path Ⅱ08 and outlet gas path Ⅱ05.

[0016] The turbocharger has two shafts: the shaft A section 8 and the shaft B section 9. Since the two shafts are on one shaft, the rotation speeds of the turbine 1, the impeller B2 and the impeller A3 are the same.

[0017] The turbine 1 is connected to the exhaust pipe of the internal combustion engine through the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com