Disc brake assembly and method of manufacture

A technology of disc brakes and components, applied in the direction of brake components, brake types, axial brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

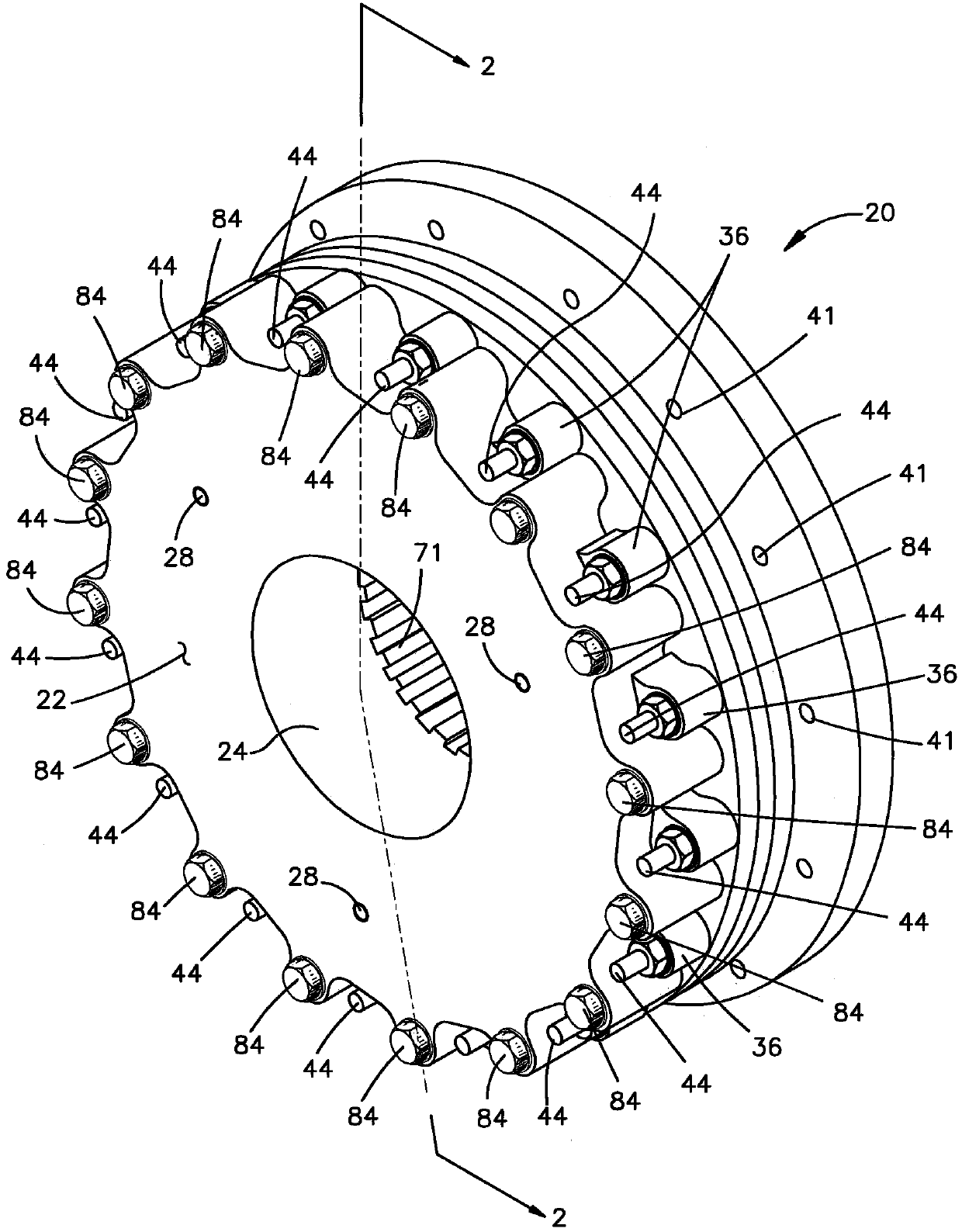

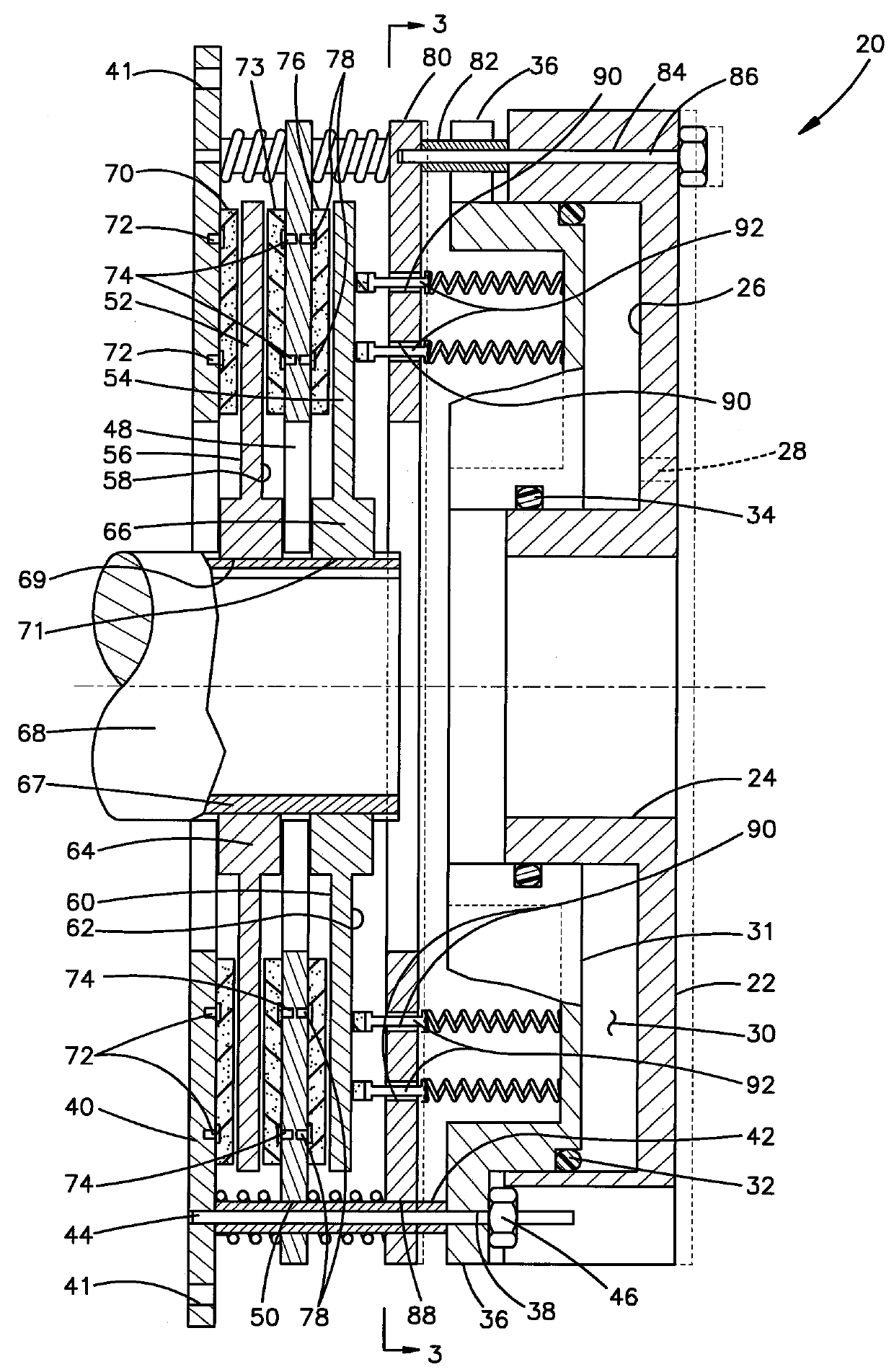

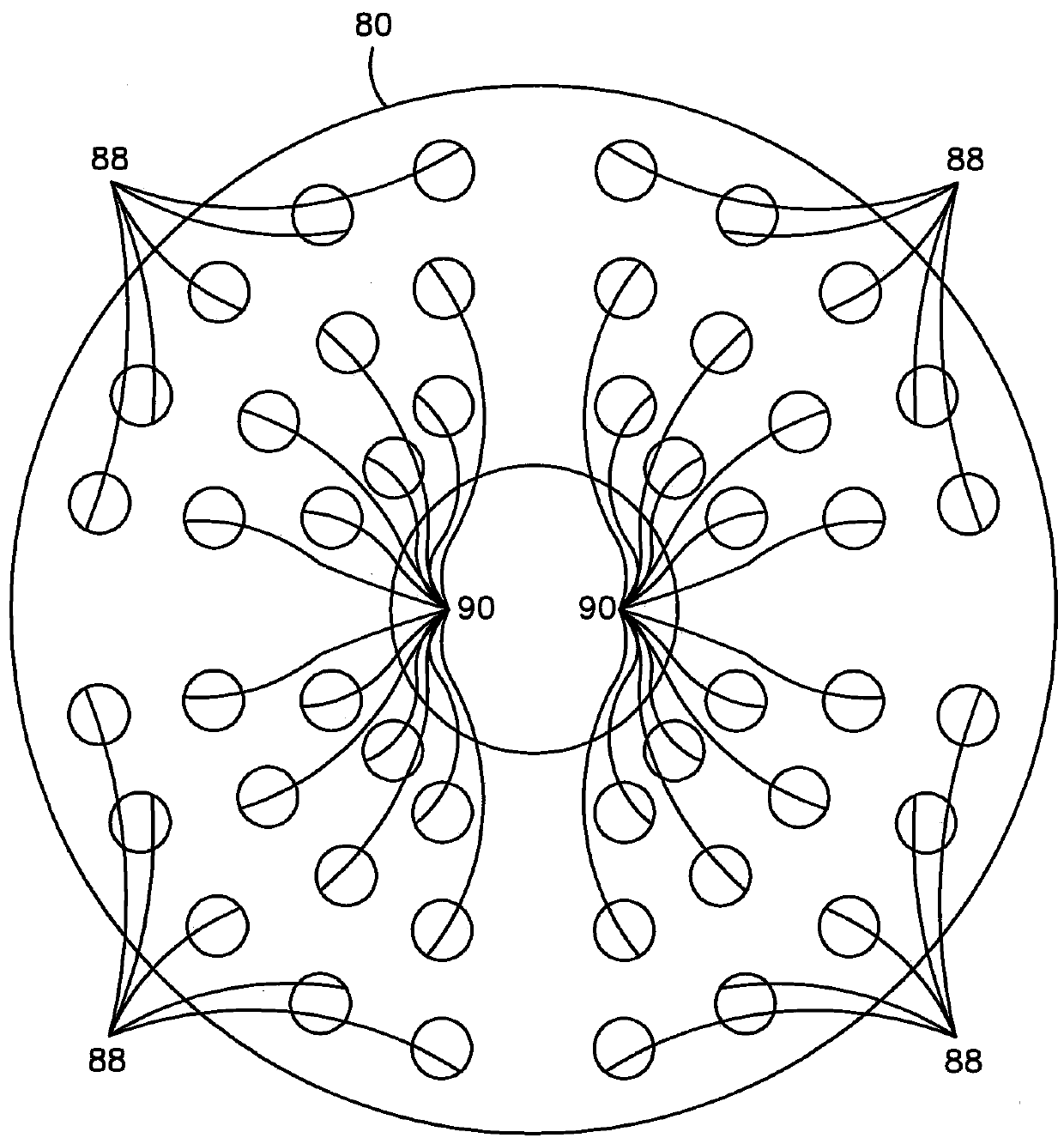

[0019] see Figure 1-5 , a disc brake assembly according to the present invention is generally indicated at 20 and includes a housing 22 of generally annular configuration with an inner circumference 24 sized to allow a rotating shaft of a desired diameter in a manner having the desired clearance through. The housing 22 includes an annular chamber 26 cooperating with an annular piston 31 disposed therein to define an annular fluid pressure chamber 30 . Chamber 30 has a plurality of fluid pressure inlets 28 formed through housing 22 . Piston 31 is sealed in annular cavity 26 around the radial periphery of cavity 26 by a suitable sealing ring 32 ; and the radial inner circumference of cavity 26 is sealed around piston 22 by an inner sealing ring 34 .

[0020] The annular piston 31 has a plurality of circumferentially spaced radially outwardly extending circumferentially spaced lugs 36 each having an aperture 38 formed axially therethrough.

[0021] An annular stationary mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com