Disc brake and vehicle

A technology of disc brakes and brake pads, applied in the direction of brake types, axial brakes, brake actuators, etc., can solve the problems of low braking comfort performance, hydraulic oil leakage, slow dynamic response of braking, etc. Achieve the effects of improving braking stability, preventing rapid wear, and uniform force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0055] In the present disclosure, the orientation words such as "inside and outside" used refer to the inside and outside of the outline of the corresponding part unless stated otherwise.

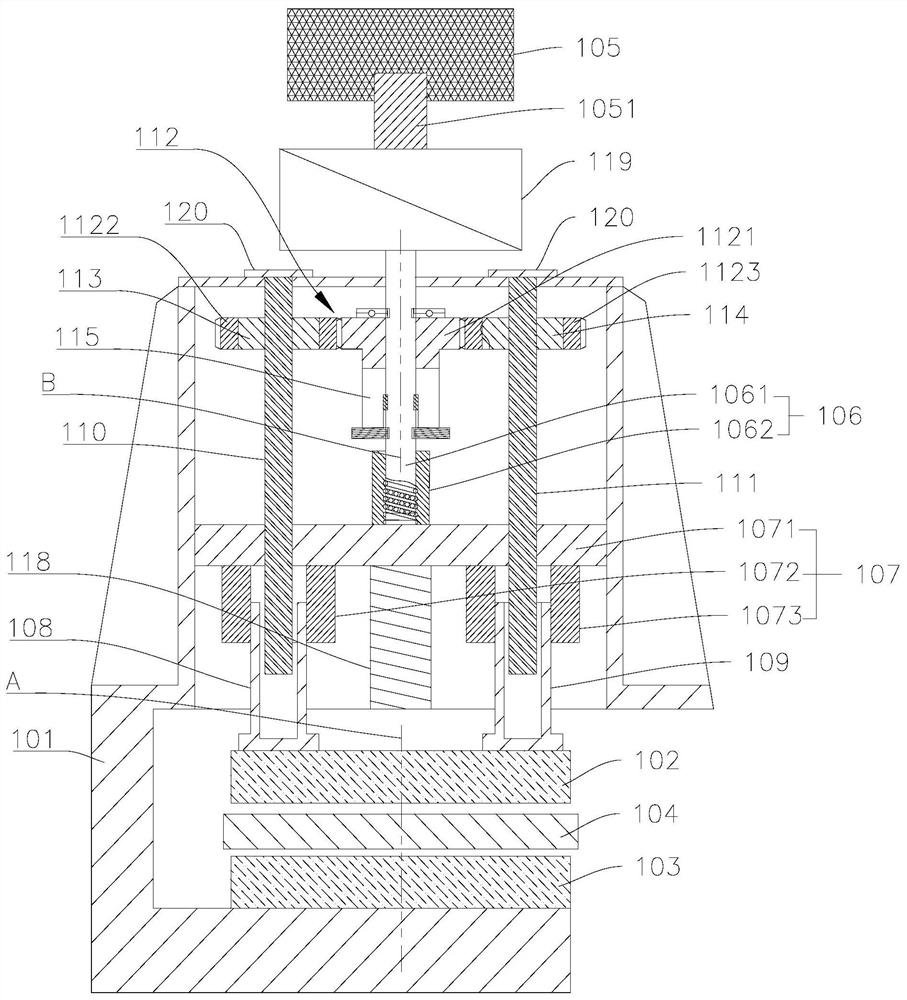

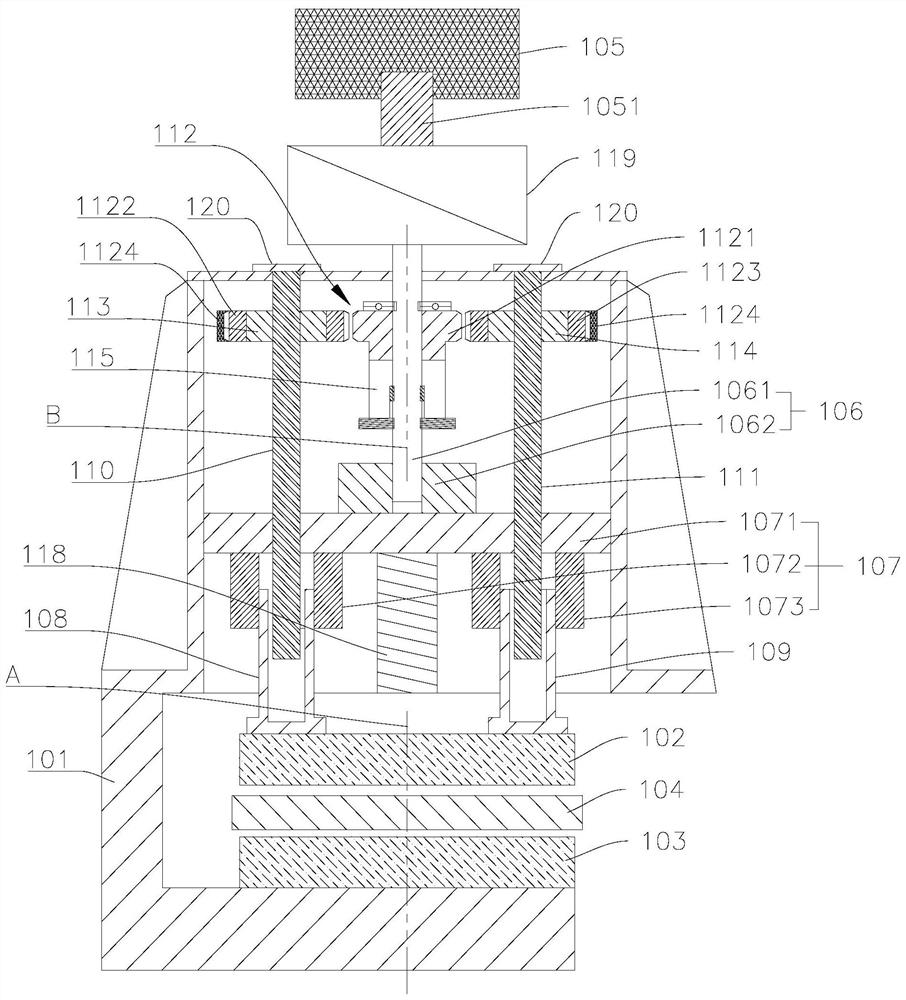

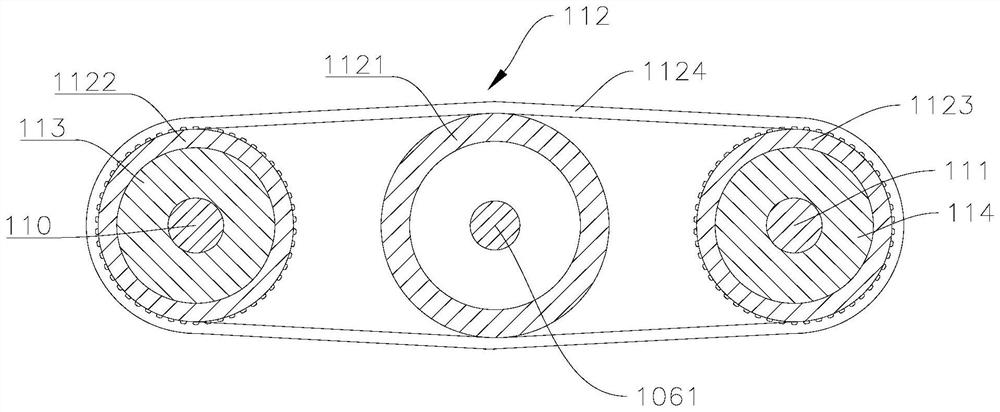

[0056] like Figure 1 to Figure 6 As shown, the present disclosure provides a disc brake, including a brake caliper body 101, a first brake block 102, a brake disc 104, a motor 105, a screw mechanism 106, a cross arm 107, a first piston 108 and a second The piston 109 and the cross arm 107 can move axially and are fixed in the brake caliper body 101. The screw mechanism 106 includes a lead screw 1061 and a nut 1062. The nut 1062 is fixed on the cross arm 107, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com