A battery set-making and screening method

A screening method and battery technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of different voltage capacities and inability to match groups, etc., and achieve the effects of improving service life, reducing costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

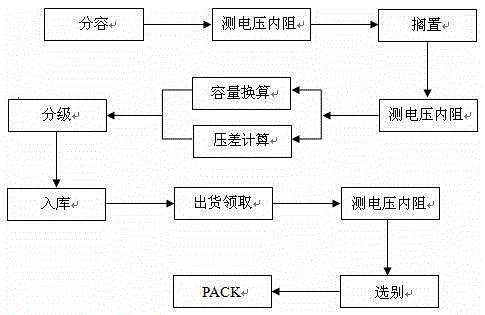

[0033] The specific battery pack screening method includes the following steps:

[0034] 1. Capacity classification, through charging and discharging the battery, the discharge capacity of the battery can be obtained, and the data can be exported to an EXCEL table.

[0035] 2. Measure the voltage internal resistance. After removing from the cabinet, use the voltage internal resistance tester to test within the specified time, and export the data to an EXCEL form.

[0036] 3. Measure the voltage internal resistance after shelving, use the voltage internal resistance tester to test the voltage internal resistance after shelving at the specified time, and export the data to the EXCEL form.

[0037] 4. Calculate the pressure difference and convert the capacity, and organize the data in the EXCEL table.

[0038] 5. Grading. According to the grading standard, the sorted data is separated into different grades and put into storage.

[0039] 6. Pick up the shipment, pick up the batt...

Embodiment 2

[0058] The method for screening battery packs includes the following steps:

[0059] 1. The capacity-distributing equipment is equipped with temperature monitoring, and the temperature of each battery is exported in the data table.

[0060] 2. The formula can convert the capacity at different temperatures into the normal temperature capacity at 25°C.

[0061] 3. Data processing requires volume software, computer and office software.

[0062] 4. The content analysis software has the function of data export.

[0063] 5. The voltage internal resistance tester is connected to the computer, and the customized software is used to convert and export to the EXCEL form.

[0064] 6. The grading standard is the standard for judging qualified products within the enterprise, which is unified with the requirements for matching groups.

[0065] 7. Batteries of the same level must meet the matching requirements, so there is no need to consider the capacity difference.

[0066] 8. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com