A kind of anti-corrosion positive grid green alloy of lead-acid storage battery

A lead-acid battery, anti-corrosion technology, applied in the direction of electrode carrier/collector, etc., can solve the problems of environmental pollution, coarse alloy crystal image, intergranular corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The anti-corrosion positive grid green alloy of the lead-acid storage battery of the present invention comprises the following components in weight percent: tin (Sn) 0.8-1.5%, calcium (Ca) 0.08-0.15%, aluminum (Al) 0.01-0.04%, cerium (Ce) 0.02-0.2%, lanthanum (La) 0.02-0.2%, neodymium (Nd) 0.02-0.2%, silver (Ag) 0.001-0.05%, the rest is lead, and the lead grade is greater than 99.99%.

[0014] The original alloy contains Pb-Ca-Sn-Al, and its alloy crystal image is coarse. Since the positive electrode is a repeated process of oxidation and reduction during use, the original composition alloy is easily oxidized in this environment to cause intergranular corrosion. In addition, it is necessary to retain the operability and high hydrogen evolution potential of the original alloy. Therefore, the refinement and consistency of the alloy crystal are mainly studied. Through a large number of scientific and reasonable experiments, it is found that the amount of Ce, La, Nd, and Ag ...

Embodiment 2

[0022] The anti-corrosion positive grid green alloy of the lead-acid storage battery of the present invention comprises the following components in weight percent: 1.0-1.2% of tin, 0.1-0.13% of calcium, 0.02-0.03% of aluminum, 0.05-0.1% of cerium, and 0.05-0.1% of lanthanum %, neodymium 0.05~0.1%, silver 0.005~0.03%, all the other are lead, others are the same as embodiment 1.

[0023] The alloy formula of Example 3-22 is shown in Table 1-2 (lead is not included, the percentage of the alloy in the table is removed, and the rest is lead), and the rest are the same as in Example 1.

[0024] Table 1 Alloy Formula Table of Embodiment 3-12 of the present invention

[0025]

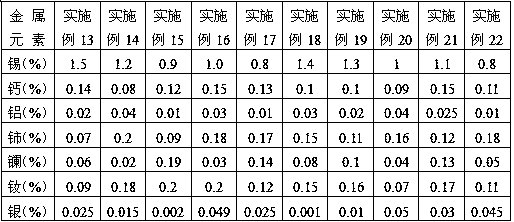

[0026] Table 2 Alloy Formula Table of Embodiment 13-22 of the present invention

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com