Flame-retardant urea-formaldehyde resin adhesive and preparation method thereof

A technology of urea-formaldehyde resin glue and flame retardant, which is applied in the direction of adhesives, adhesive additives, aldehyde/ketone condensation polymer adhesives, etc. It can solve the problems of fire hazards, poor thermal stability of urea-formaldehyde resin, etc., and achieve retention and dispersion Performance, ease of reaction conditions, and improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

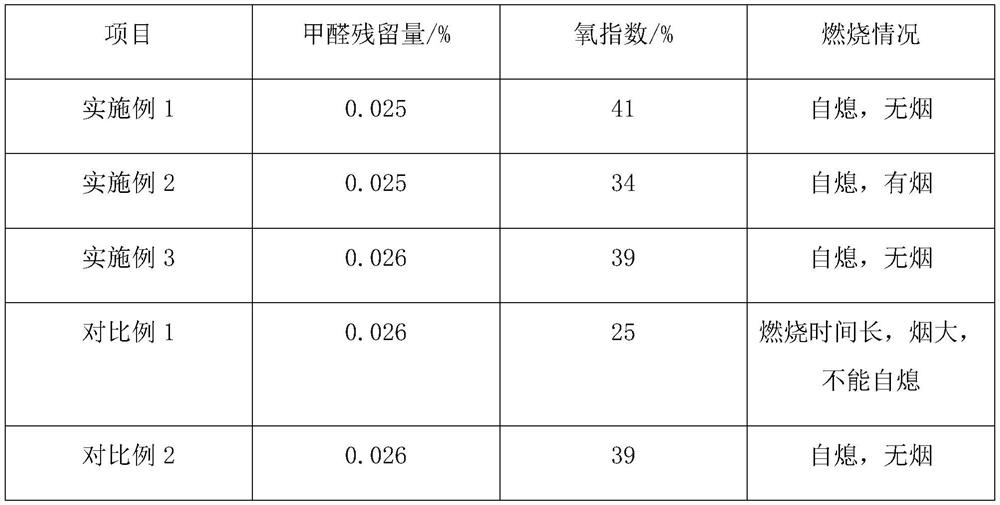

Examples

Embodiment 1

[0031] A preparation method of a flame-retardant urea-formaldehyde resin adhesive, comprising the following steps:

[0032] (1) Prepare modified inorganic mineral particles: use deionized water to disperse 100g inorganic mineral particles (200 mesh) and configure a concentration of 15wt% inorganic mineral particle slurry, wherein antimony trioxide and other hydroxides in the inorganic mineral particles The mass ratio is 1:3, and stearic acid is added after heating to 85°C in a water bath to configure a modified reaction solution with a stearic acid concentration of 6wt%, allowing it to react under 20Khz ultrasonic vibration for 45min, and then place it in a centrifuge Within 10 minutes, the condition of rotating speed of 8000 rpm was maintained to obtain modified inorganic mineral particles. The mass ratio of antimony trioxide to other hydroxides in the inorganic mineral particles is 1:3.

[0033] (2) Preparation of flame retardant: After mixing the modified inorganic mineral...

Embodiment 2

[0045] A preparation method of a flame-retardant urea-formaldehyde resin adhesive, comprising the following steps:

[0046] (1) Prepare modified inorganic mineral particles: use deionized water to disperse 50g inorganic mineral particles (200 mesh) and configure a concentration of 15wt% inorganic mineral particle slurry, wherein antimony trioxide and other hydroxides in the inorganic mineral particles The mass ratio is 1:3, and stearic acid is added after heating to 85°C in a water bath to configure a modified reaction solution with a stearic acid concentration of 6wt%, allowing it to react under 20Khz ultrasonic vibration for 45min, and then place it in a centrifuge Within 10 minutes, the condition of rotating speed of 8000 rpm was maintained to obtain modified inorganic mineral particles.

[0047] (2) Preparation of flame retardant: After mixing the modified inorganic mineral particles with 15g of tris(2-chloroethyl)phosphate, dilute with 100mL of acetone, let it react under...

Embodiment 3

[0050] A preparation method of a flame-retardant urea-formaldehyde resin adhesive, comprising the following steps:

[0051] (1) Prepare modified inorganic mineral particles: use deionized water to disperse 100g inorganic mineral particles (200 mesh) and configure a concentration of 15wt% inorganic mineral particle slurry, wherein antimony trioxide and other hydroxides in the inorganic mineral particles The mass ratio is 1:5, and stearic acid is added after heating to 85°C in a water bath to configure a modified reaction solution with a stearic acid concentration of 6wt%, allowing it to react under 20Khz ultrasonic vibration for 45min, and then place it in a centrifuge Within 10 minutes, the condition of rotating speed of 8000 rpm was maintained to obtain modified inorganic mineral particles.

[0052] (2) Preparation of flame retardant: After mixing the modified inorganic mineral particles with 30g of tris(2-chloroethyl) phosphate, dilute with 200mL of acetone, let it react und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com