Process for high temperature removal of trace chloride contaminants in a catalytic dehydrogenation process

A technology for catalytic dehydrogenation and chloride, applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve problems such as not very effective, high production cost, unsatisfactory large pressure drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

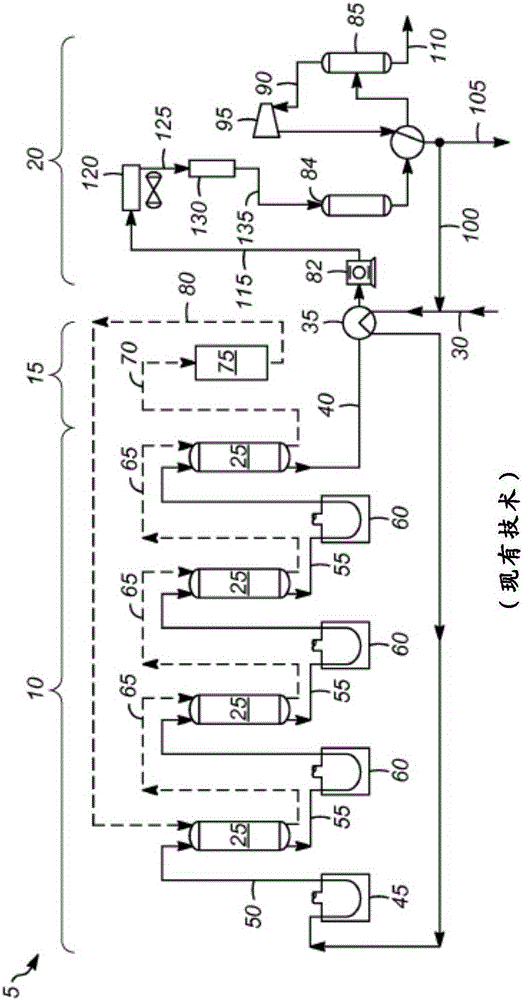

[0020] At higher temperatures, undesirable side reactions on chloride adsorbents, such as acid-catalyzed polymerization, oligomerization, cyclization and the tendency to form heavy residues by condensation, generally increase. In addition, higher temperatures are believed to unduly reduce the adsorbent capacity of the adsorption process. It is believed that optimum performance of the chloride remover can be achieved with a cooled product stream from a cooler downstream of the reactor effluent compressor in the catalytic dehydrogenation unit. Therefore, conventionally, the chloride remover is located downstream of the compressor and downstream of the cooler to impart increased adsorbent capacity, such as figure 1 shown.

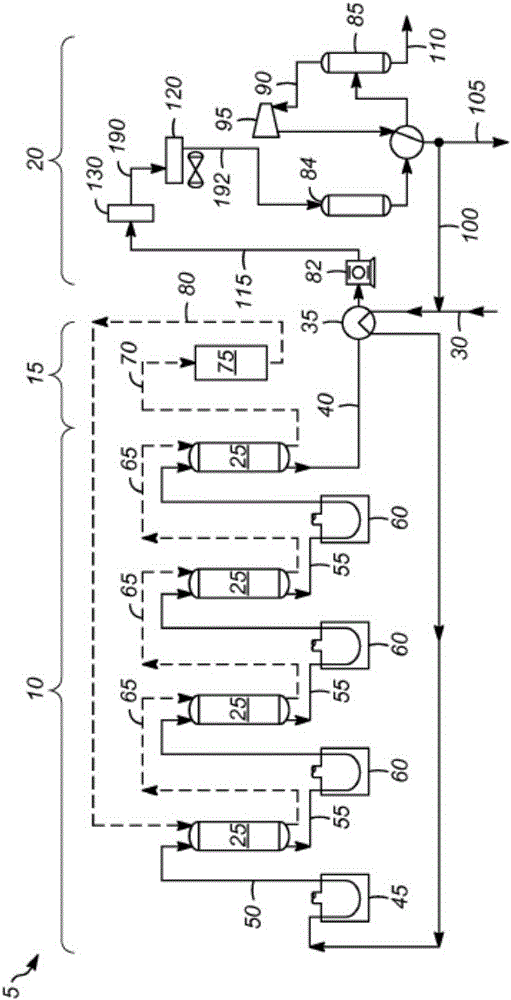

[0021] However, if there is an efficient adsorbent with suitable properties, such as low reactivity to olefin polymerization and high capacity at high operating temperatures, it is preferred that the chloride remover be located on the hotter stream prior to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com