Micro-boiling steaming method applicable to steamed bun making machine and corresponding steamed bun making machine

A steamed bun machine and micro-boiling technology, applied in steam cooking utensils, heating devices, etc., can solve the problems of wasting energy, affecting the service life of kitchen appliances, and less research and development energy, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

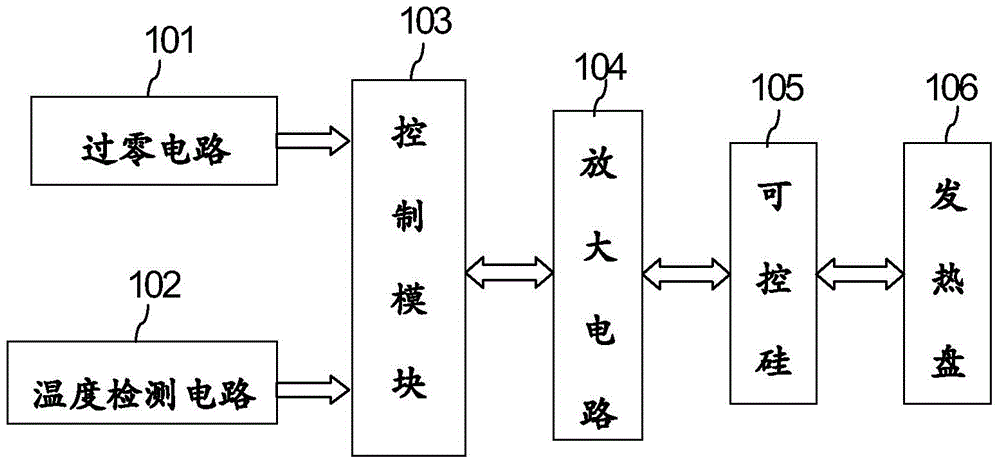

[0028] reference Figure 1 to Figure 4 , A steamed bread maker, comprising a cooking cavity composed of a cover 501 and an outer barrel 504, the outer barrel 504 is set on the top surface of the body 506, and a stirring drive device 505 is provided in the body 506. Furthermore, a mixing bucket 502 is provided in the cooking cavity, and a mixing blade 503 capable of linkage with the mixing driving device 505 is fixed in the mixing bucket 502, and the mixing bucket 502 can be fixed in the middle of the outer bucket 504.

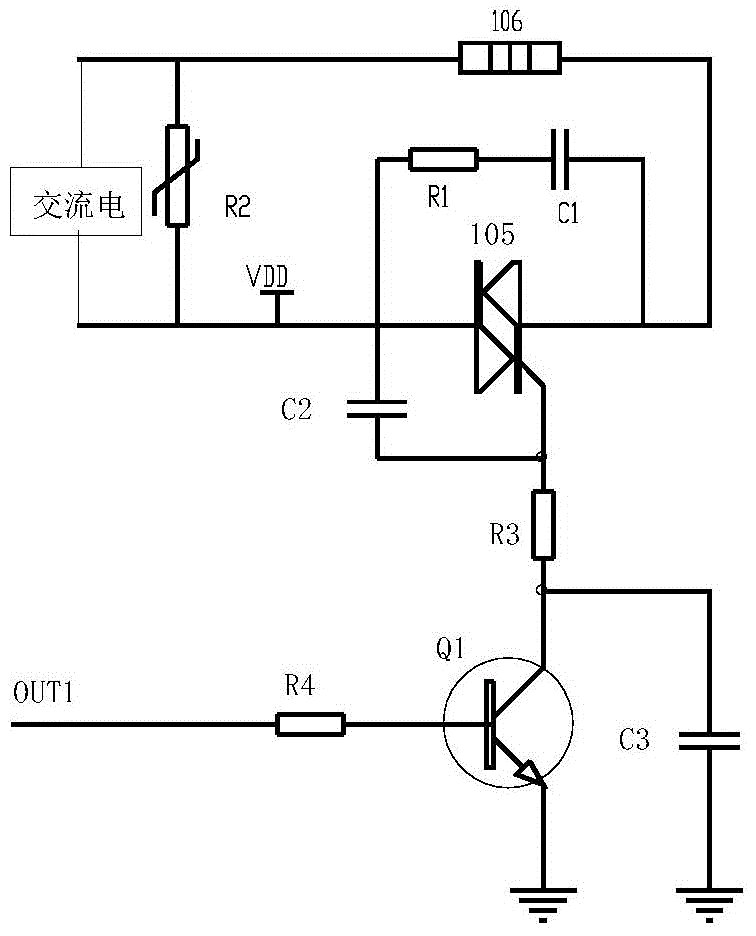

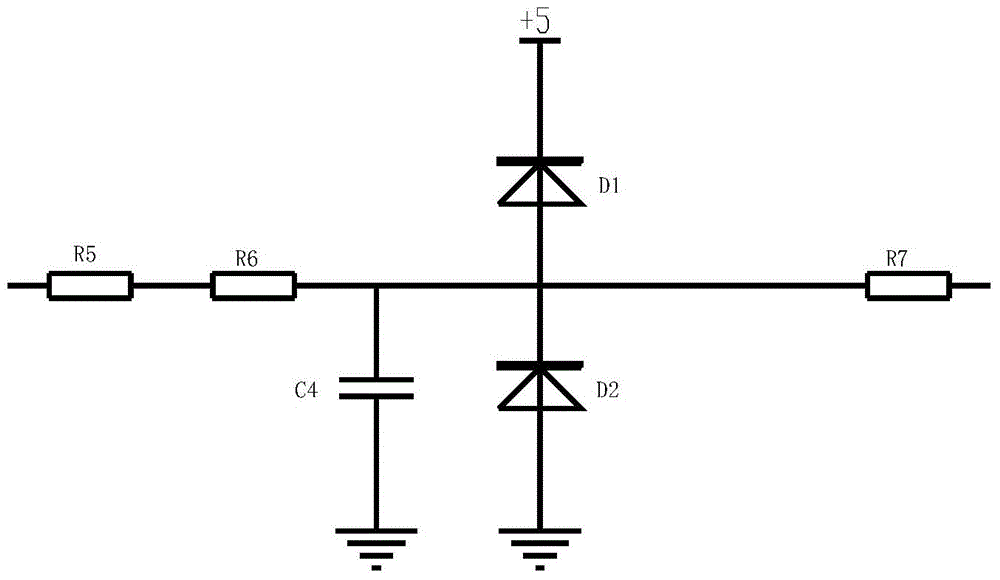

[0029] The inner bottom of the outer barrel 504 can store water and a heating plate 106 is provided on the outer bottom surface of the outer barrel 504. At this time, the outer barrel 504 and the heating plate 106 constitute a heating device that provides steam for the cooking cavity. Further, a temperature sensor R9 is provided on the inner wall of the outer tub 504, and the temperature sensor R9 penetrates into the cooking cavity and is a part of the temperature...

Embodiment 2

[0034] based on Figure 1 to Figure 4 , A micro-boiling steaming method suitable for a steamed bun maker. The steamed bun maker includes a cooking cavity, a temperature sensor R9 that can detect the temperature in the cooking cavity, a heating device that can provide steam to the cooking cavity, and a control module 103. Add 50g to 300g of water into the heating device in advance, and control the temperature range of the water in the heating device at 15 degrees to 45 degrees. This method should only start to run after the ingredients in the steamed bun machine have been mixed and fermented, that is, the dough can be heated to form steamed buns.

[0035] The method includes the following steps:

[0036] (1) Pre-heating mode: When the dough in the cooking cavity needs to be steamed, the control module 103 controls the heating device to heat with the first power, and the first power range is 500W-1300W;

[0037] (2) Slight boiling mode: When the control module 103 detects that the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com