Mixed-color water-absorbing antiskid non-woven fabric and manufacturing method thereof

A production method, non-woven technology, applied in the direction of chemical instruments and methods, lamination auxiliary operations, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

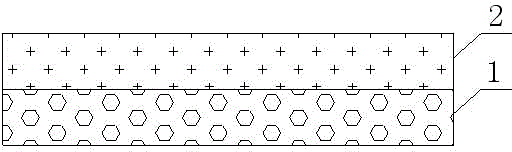

[0017] Embodiment 1: A variegated water-absorbing and non-slip non-woven fabric, the variegated water-absorbing and non-slip non-woven fabric is composed of two layers of variegated non-woven fabric layer 1 and PE film layer 2, and the PE film layer 2 is compounded on the variegated non-woven fabric layer 1 by laminating technology.

[0018] A method for making a variegated water-absorbing non-slip non-woven fabric, the steps of which are:

[0019] (1) The variegated non-woven fabric layer 1 is prepared by acupuncture method;

[0020] (2) PE film layer 2 is coated on one side of the variegated non-woven fabric layer 1, and the coating temperature is controlled at 300 degrees Celsius;

[0021] (3) Cool the variegated non-woven fabric coated in step 2 to normal temperature, roll it into a roll and pack it, and then prepare variegated water-absorbing and non-slip non-woven fabric.

Embodiment 2

[0022] Embodiment 2: A variegated water-absorbing and non-slip non-woven fabric, the variegated water-absorbing and non-slip non-woven fabric is composed of two layers of variegated non-woven fabric layer 1 and PE film layer 2, and the PE film layer 2 is compounded on the variegated non-woven fabric layer 1 by laminating technology.

[0023] A method for making a variegated water-absorbing non-slip non-woven fabric, the steps of which are:

[0024] (1) The variegated non-woven fabric layer 1 is prepared by acupuncture method;

[0025] (2) PE film layer 2 is coated on one side of the variegated non-woven fabric layer 1, and the coating temperature is controlled at 295 degrees Celsius;

[0026] (3) Cool the variegated non-woven fabric coated in step 2 to normal temperature, roll it into a roll and pack it, and then prepare variegated water-absorbing and non-slip non-woven fabric.

Embodiment 3

[0027] Embodiment 3: A variegated water-absorbing and non-slip non-woven fabric, the variegated water-absorbing and non-slip non-woven fabric is composed of two layers of variegated non-woven fabric layer 1 and PE film layer 2, and the PE film layer 2 is compounded on the variegated non-woven fabric layer 1 by laminating technology.

[0028] A method for making a variegated water-absorbing non-slip non-woven fabric, the steps of which are:

[0029] (1) The variegated non-woven fabric layer 1 is prepared by acupuncture method;

[0030] (2) PE film layer 2 is coated on one side of the variegated non-woven fabric layer 1, and the coating temperature is controlled at 310 degrees Celsius;

[0031] (3) Cool the variegated non-woven fabric coated in step 2 to normal temperature, roll it into a roll and pack it, and then prepare variegated water-absorbing and non-slip non-woven fabric.

[0032] The invention relates to a variegated water-absorbing and non-slip non-woven fabric. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com