Multi-station hopper

A multi-station and hopper technology, which is applied to conveyors, vibrating conveyors, transportation and packaging, etc., can solve the problem that raw materials cannot be delivered to different positions, so as to save waiting time for feeding and improve work efficiency , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

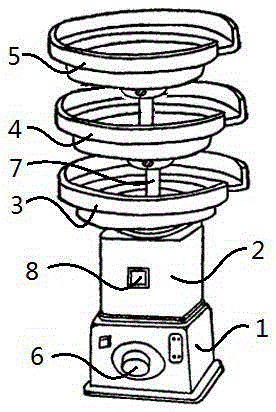

[0021] The reference signs in the accompanying drawings include: controller 1 , electromagnetic vibrator 2 , first feeding tray 3 , second feeding tray 4 , third feeding tray 5 , adjustment button 6 , rotating shaft 7 , and start switch 8 .

[0022] Such as figure 1 As shown, the multi-station hopper includes a controller 1 , an electromagnetic vibrator 2 , a first feeding tray 3 , a second feeding tray 4 and a third feeding tray 5 from bottom to top. The first feeding tray 3 , the second feeding tray 4 and the third feeding tray 5 are all connected to the controller 1 through a rotating shaft 7 . The coil spring supporting the first feeding tray 3 is connected between the electromagnetic vibrator 2 and the first feeding tray 3, and the first feeding tray 3, the second feeding tray 4 and the third feeding tray 5 all adopt soft iron and are installed on the electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com