Epoxy resin composition

A technology of epoxy resin and composition, applied in the field of polymer materials, can solve problems such as cracks, weak crack resistance, damage, etc., and achieve the effects of reduced viscosity, high impact strength and bending strength, and good flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

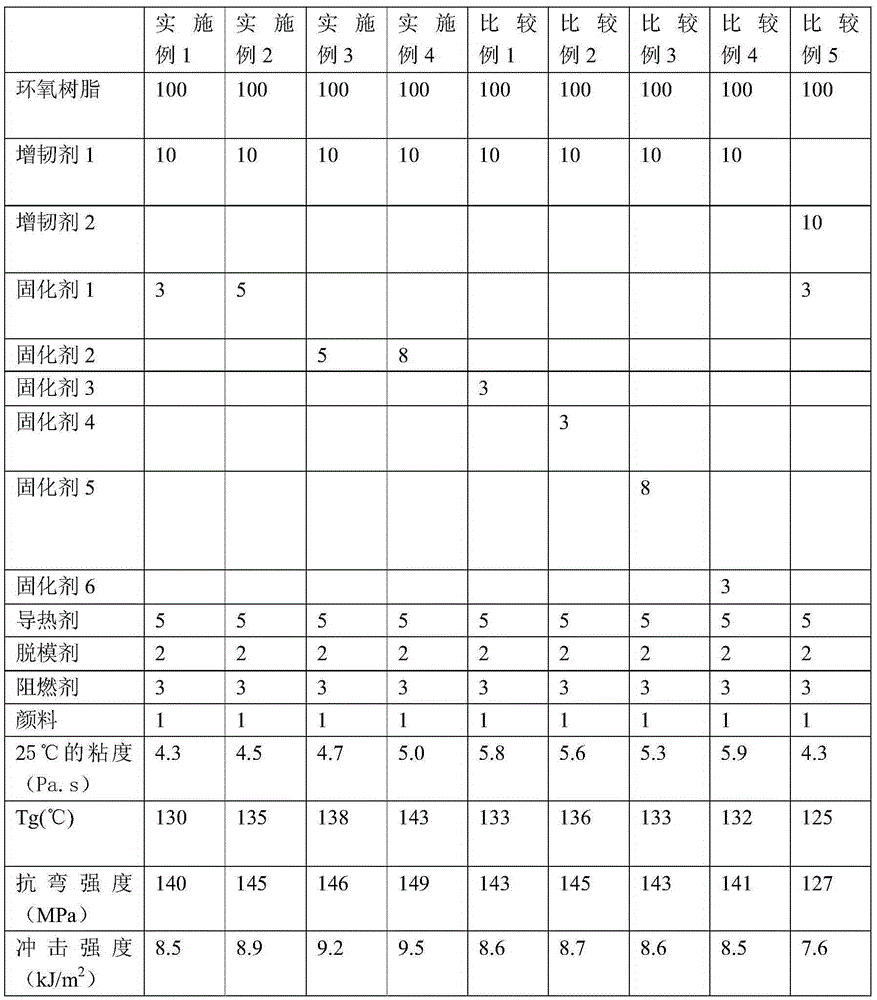

Examples

Embodiment 5

[0046] Embodiment 5 (application example)

[0047] (1) Preheat the coil winding at 100°C for 6 hours, and cool to 60°C before pouring;

[0048] (2) will accurately weigh each raw material of epoxy resin composition by the ratio in embodiment 1, at normal temperature, in vacuum tightness 1-3mbar, stirring and defoaming 3 hours;

[0049] (3) Place the coil winding in the pouring tank and vacuumize for 2 hours under the state of vacuum degree 3mbar;

[0050] (4) Pouring the epoxy resin composition into the pouring tank, keeping a vacuum of 4mbar, and soaking for 3 hours;

[0051] (5) Place the impregnated coil winding in a curing oven, keep it at 80°C for 3 hours, raise the temperature to 90°C in 30 minutes, and keep it for 1.5 hours; raise the temperature to 110°C in 30 minutes, keep it for 2.5 hours; raise the temperature to 140°C in 60 minutes , Keep for 10 hours for final curing.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap