Tile binder

A tile adhesive and titanium slag technology, which is applied in the field of chemical building materials, can solve the problems of poor acid and alkali corrosion resistance, and achieve the effects of enhancing anti-slip performance, improving mechanical properties, and increasing working strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

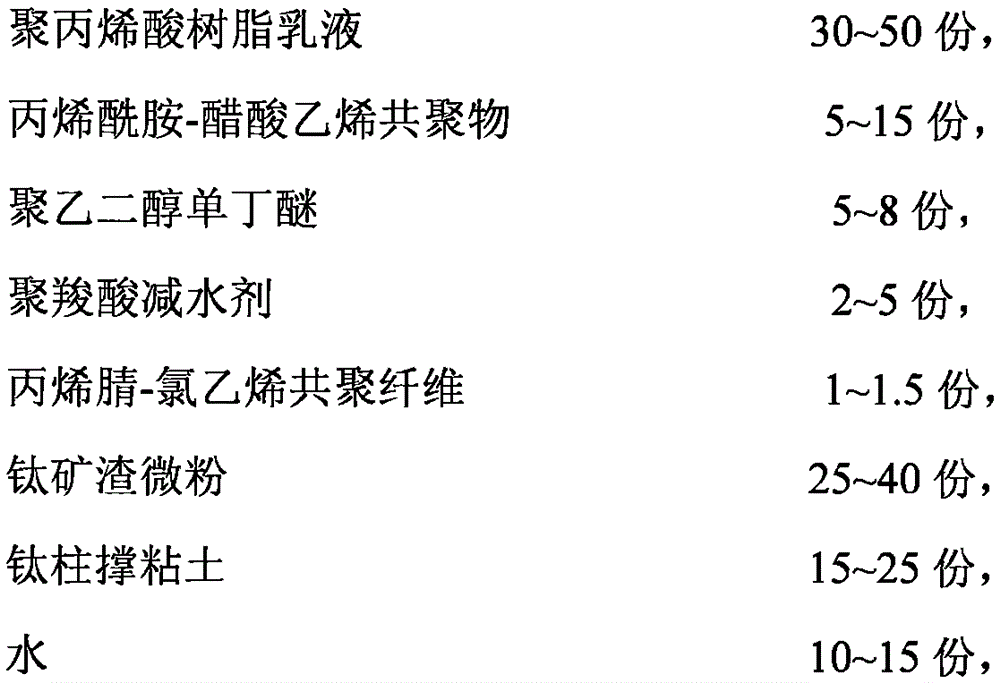

[0027] The ceramic tile adhesive of the present embodiment is made up of the raw material of following weight part:

[0028]

[0029] Among them, the specific surface area of titanium slag powder is 350m 2 / g, the particle size is 100 μm.

[0030] The preparation method of above-mentioned ceramic tile adhesive, comprises the steps:

[0031] Mix titanium slag micropowder and polyacrylic acid resin emulsion evenly and let it stand for 2 hours, then add water and stir for 1 hour at 35°C, let it stand for 30 minutes, add titanium pillared clay and stir for 1 hour, then add acrylamide to the mixed emulsion - Mix vinyl acetate copolymer, polyethylene glycol monobutyl ether, polycarboxylate water reducer, and acrylonitrile-vinyl chloride copolymer fibers uniformly to obtain tile adhesive.

Embodiment 2

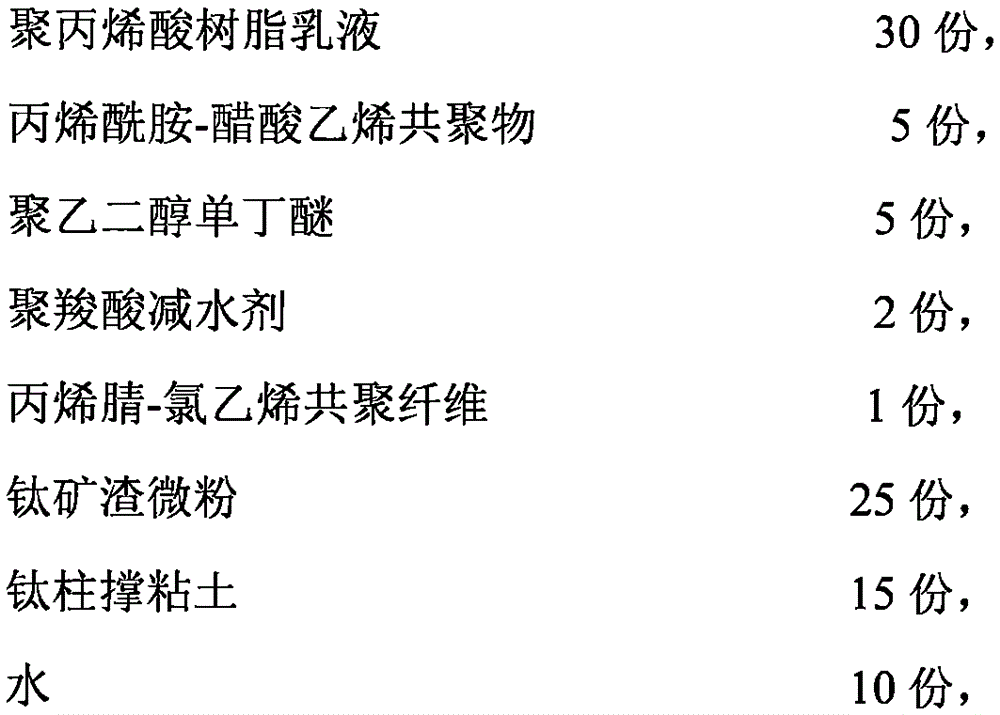

[0033] The ceramic tile adhesive of the present embodiment is made up of the raw material of following weight part:

[0034]

[0035] Among them, the specific surface area of titanium slag powder is 400m 2 / g, the particle size is 90 μm.

[0036] The preparation method of above-mentioned ceramic tile adhesive, comprises the steps:

[0037] Mix titanium slag micropowder and polyacrylic acid resin emulsion evenly, then let stand for 4 hours, add water and stir for 2 hours at 60°C, let stand for 45 minutes, add titanium pillared clay and stir for 2 hours, add acrylamide to the mixed emulsion - mixing and mixing vinyl acetate copolymer, polyethylene glycol monobutyl ether, polycarboxylate water reducing agent, and acrylonitrile-vinyl chloride copolymer fiber to obtain tile adhesive.

Embodiment 3

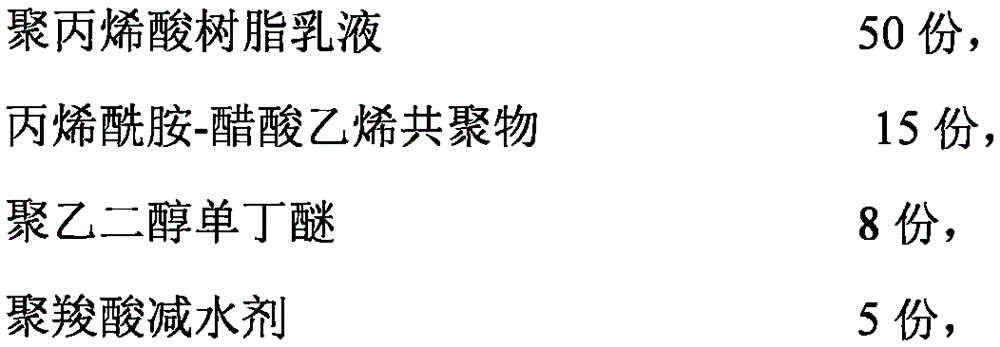

[0039] Ceramic tile adhesive is made up of the following raw materials of weight part:

[0040]

[0041]

[0042] Among them, the specific surface area of titanium slag powder is 420m 2 / g, particle size 85μm.

[0043] The preparation method of above-mentioned ceramic tile adhesive, comprises the steps:

[0044] Mix titanium slag fine powder and polyacrylic acid resin emulsion evenly and let it stand for 3 hours, add water and stir for 1.5 hours at 50°C, let stand for 35 minutes, add titanium pillared clay and stir for 1.5 hours, add to the mixed emulsion Acrylamide-vinyl acetate copolymer, polyethylene glycol monobutyl ether, polycarboxylate water reducer, and acrylonitrile-vinyl chloride copolymer fiber are uniformly mixed to obtain a ceramic tile adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com