Intake air recirculation fittings with ring cavity

A technology for recirculation pipes and intake pipes, which is applied to engine components, combustion air/combustion-air treatment, internal combustion piston engines, etc. It can solve the problems of affecting the working efficiency of the impeller, different guiding effects of the wind deflector, and increasing the impact of the impeller. , to achieve the effect of ensuring smooth air intake, low cost and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and drawings.

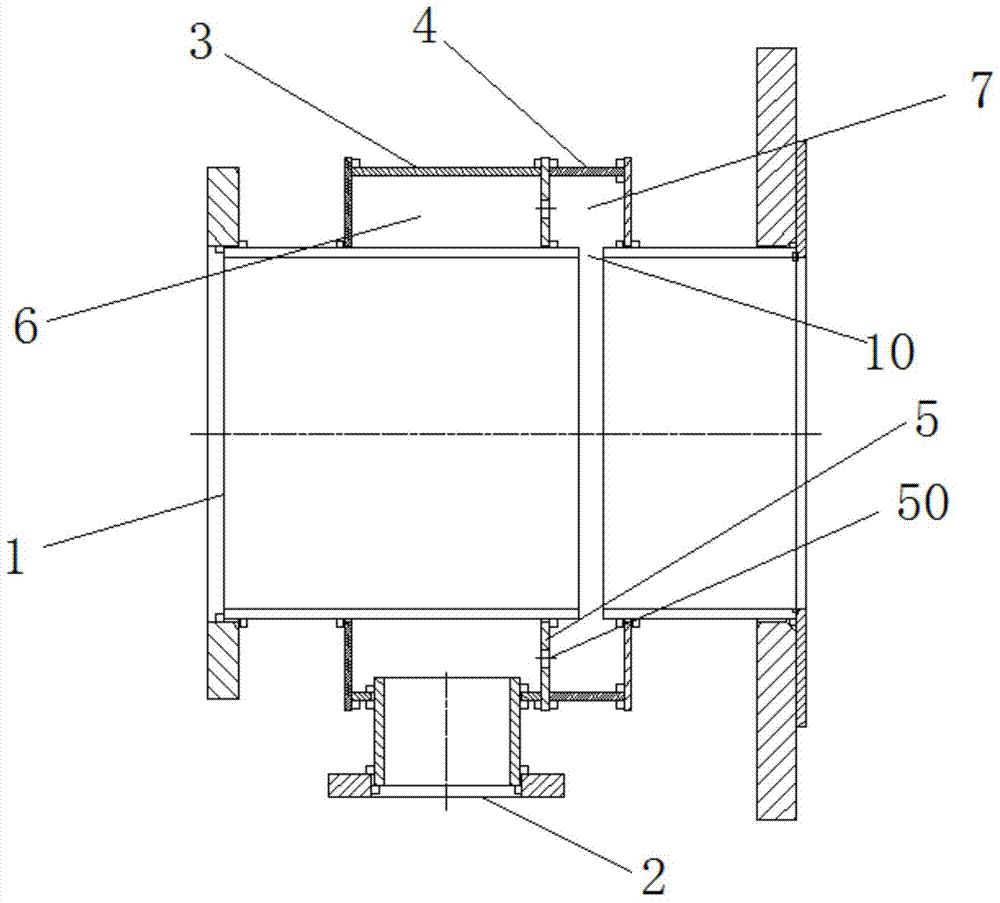

[0014] Such as figure 1 The shown intake recirculation pipe fitting with a ring cavity includes a main pipe 1. The main pipe 1 is sleeved with a first ring 3 and a second ring 4 side by side. The first ring 3 and the second ring A first ring cavity 6 and a second ring cavity 7 are formed between the ring 4 and the main pipe 1, and the first ring 3 and the second ring 4 are connected to the main pipe 1 by welding. The diameters of the first loop 3 and the second loop 4 are the same and larger than the outer diameter of the main pipe 1. The length of the first loop 3 is greater than the length of the second loop 4, so that the first loop cavity 6 The volume is greater than the volume of the second ring cavity 7, so that the circulating air can smoothly enter the second ring cavity 7 from the first ring cavity 6 to ensure the normal air intake of the main flow channel an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com