Embedded cooler for electro-hydraulic servo mechanism and cooling method

A technology of electro-hydraulic servo and servo mechanism, which is applied in the direction of mechanical equipment, fluid pressure actuation device, fluid pressure actuation system components, etc., and can solve the problem of extremely strict external size and weight limit, increase of cooler external size, Reduce the reliability of the cooler and other issues, and achieve the effect of obvious weight reduction, good sealing effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

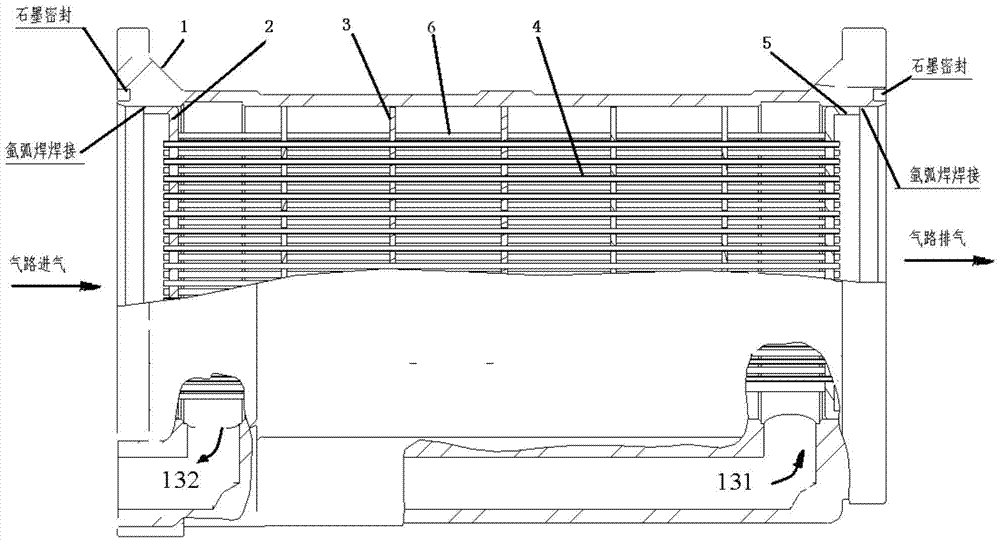

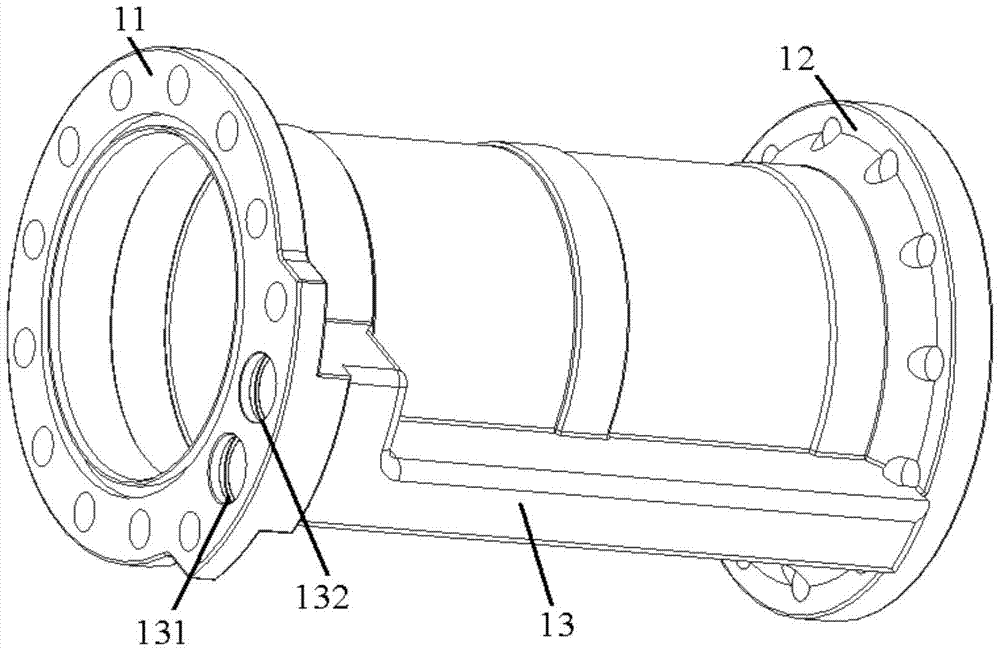

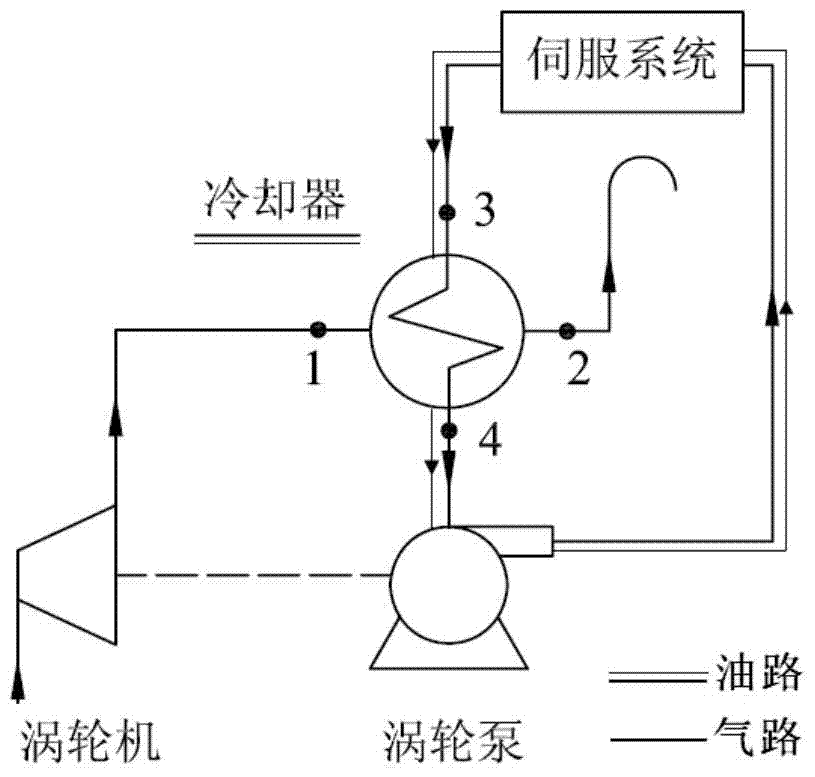

[0046] The hydrogen cooler of the present invention adopts an integrated stainless steel tubular structure, figure 1 It is a structural schematic diagram of the cooler of the present invention, which is mainly composed of a stainless steel shell 1 , a front end plate 2 , a baffle plate 3 , a tube bundle 4 , a rear end plate 5 , and a support rod 6 .

[0047]The stainless steel shell 1 is a load-bearing part, and is screwed to the main structure of the servo mechanism through flanges at both ends. All the capillary tube bundles 4 pass through the baffle plate 3, the front end plate 2 and the rear end plate 5, and are welded with the front end plate 2 and the rear end plate 5 by brazing; the front end plate 2 and the stainless steel shell 1 are welded by argon arc welding; the rear end Plate 5 and stainless steel shell 1 are welded by argon arc welding.

[0048] Both ends of the stainless steel shell 1 and the main body of the servo mechanism are sealed with flexible graphite; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com