Honeycomb briquette priming device

A fire starter and briquette technology, applied in the direction of combustion ignition, incandescent ignition, combustion methods, etc., can solve the problems of waste, slow coal ignition, heavy pollution, etc., and achieve the effect of enhancing combustion effect, reducing pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

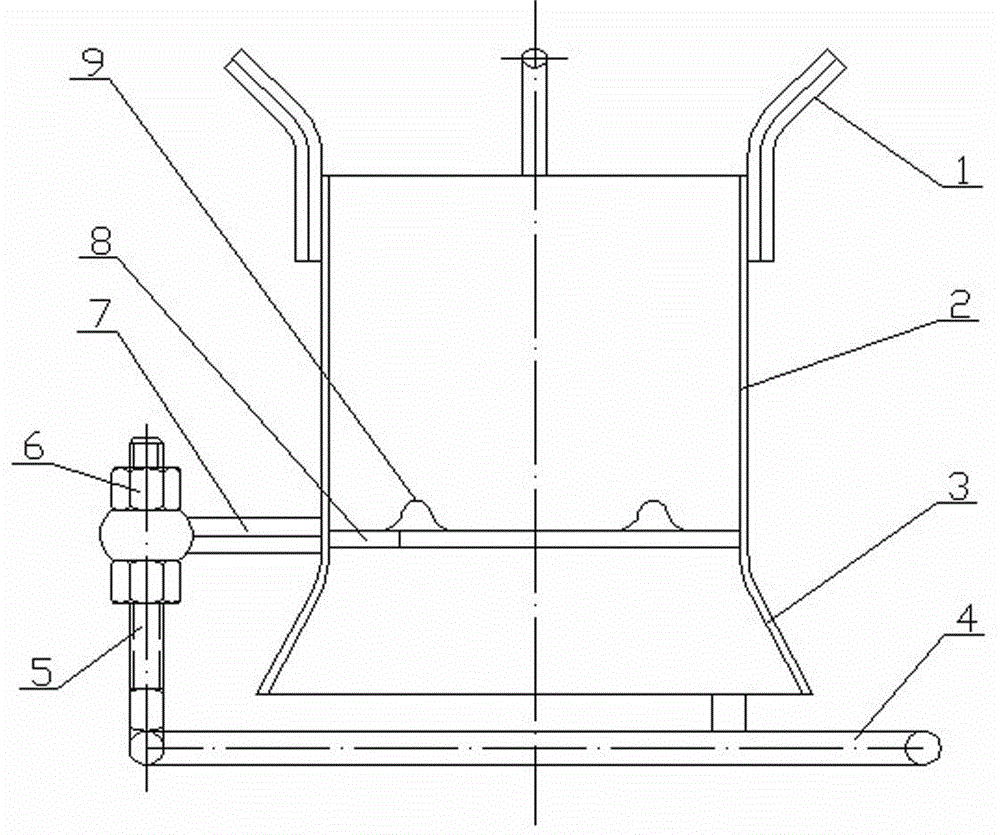

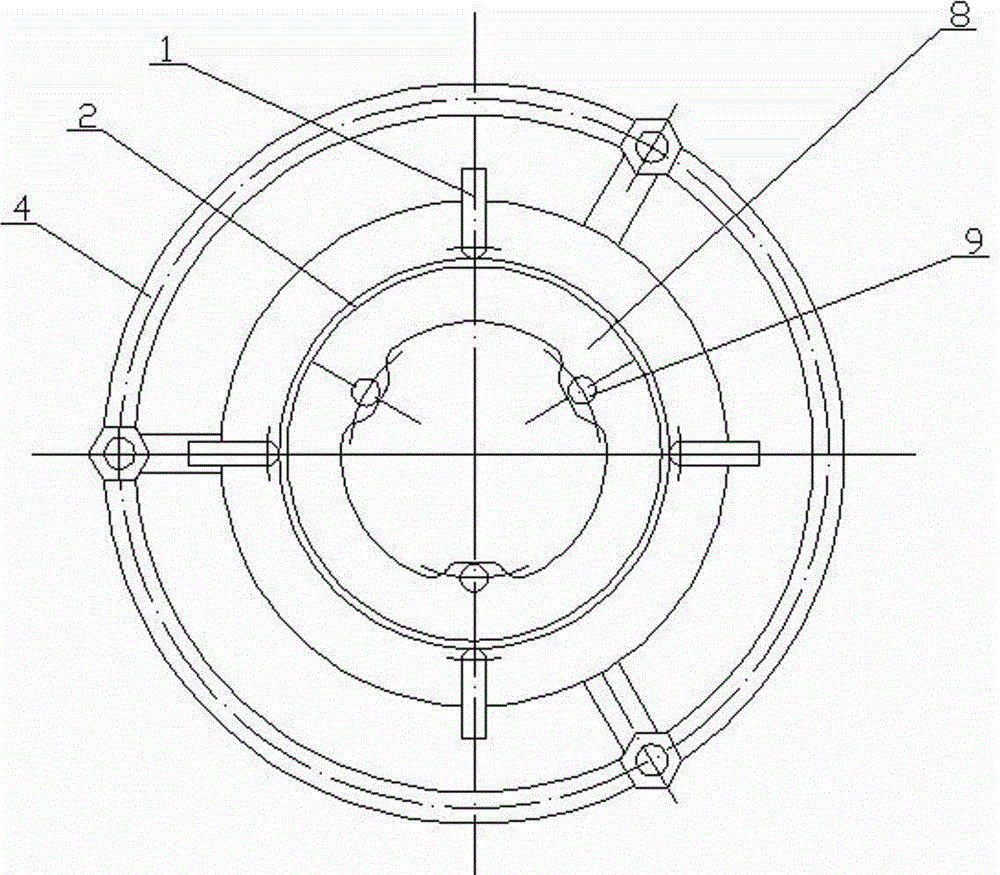

[0009] see figure 1 , figure 2 The lower end of the fire starter 2 has a bell mouth 3, and the upper port is provided with a support claw 1, and the root of the bell mouth of the fire starter inner chamber is provided with an annular support plate 8, and the upper surface of the support plate has three evenly distributed bosses 9, There is a bottom ring 4 with a diameter larger than the lower edge of the bell mouth under the fire starter. The two are connected by an adjustment rod. The adjustment rod is composed of a horizontal connecting rod 7, a screw rod 5 and a lock nut 6. The fire starter is welded into one by inner and outer layers. , There is a closed cavity between the two layers, the inner diameter of the straight part of the fire starter is 110mm, the distance between the support plate and the bell mouth port is 35mm, and the distance from the upper port of the fire starter is 85mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com