Automotive Lithium Ion Starter Battery

A technology for starting batteries and lithium ions, which is applied to secondary batteries, battery pack components, circuits, etc. It can solve the problems of poor positioning effect of battery packs, poor heat dissipation of battery packs, and high space occupancy, achieving positioning and Good heat dissipation, low space occupancy, and reduced risk of positive and negative short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

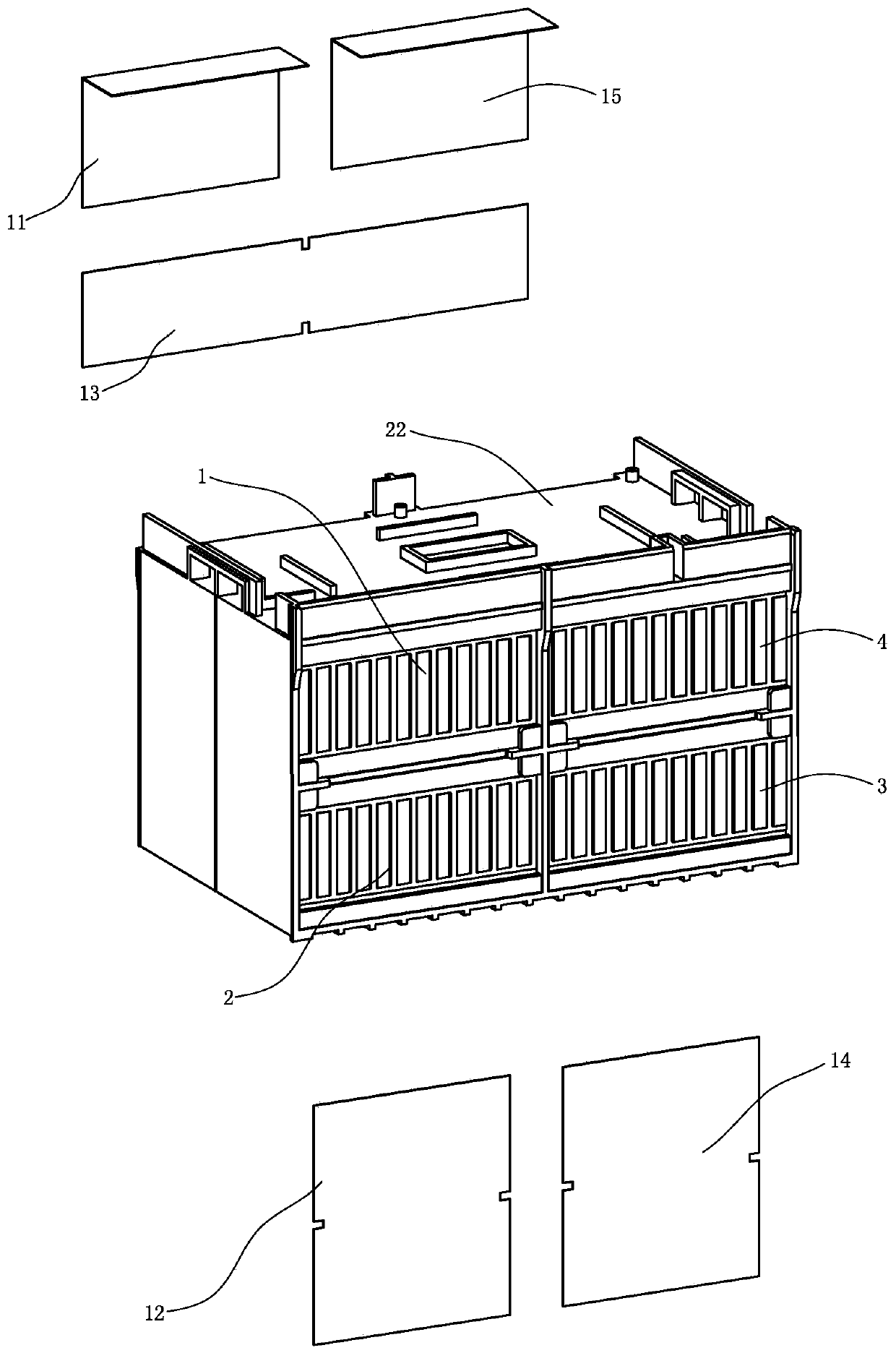

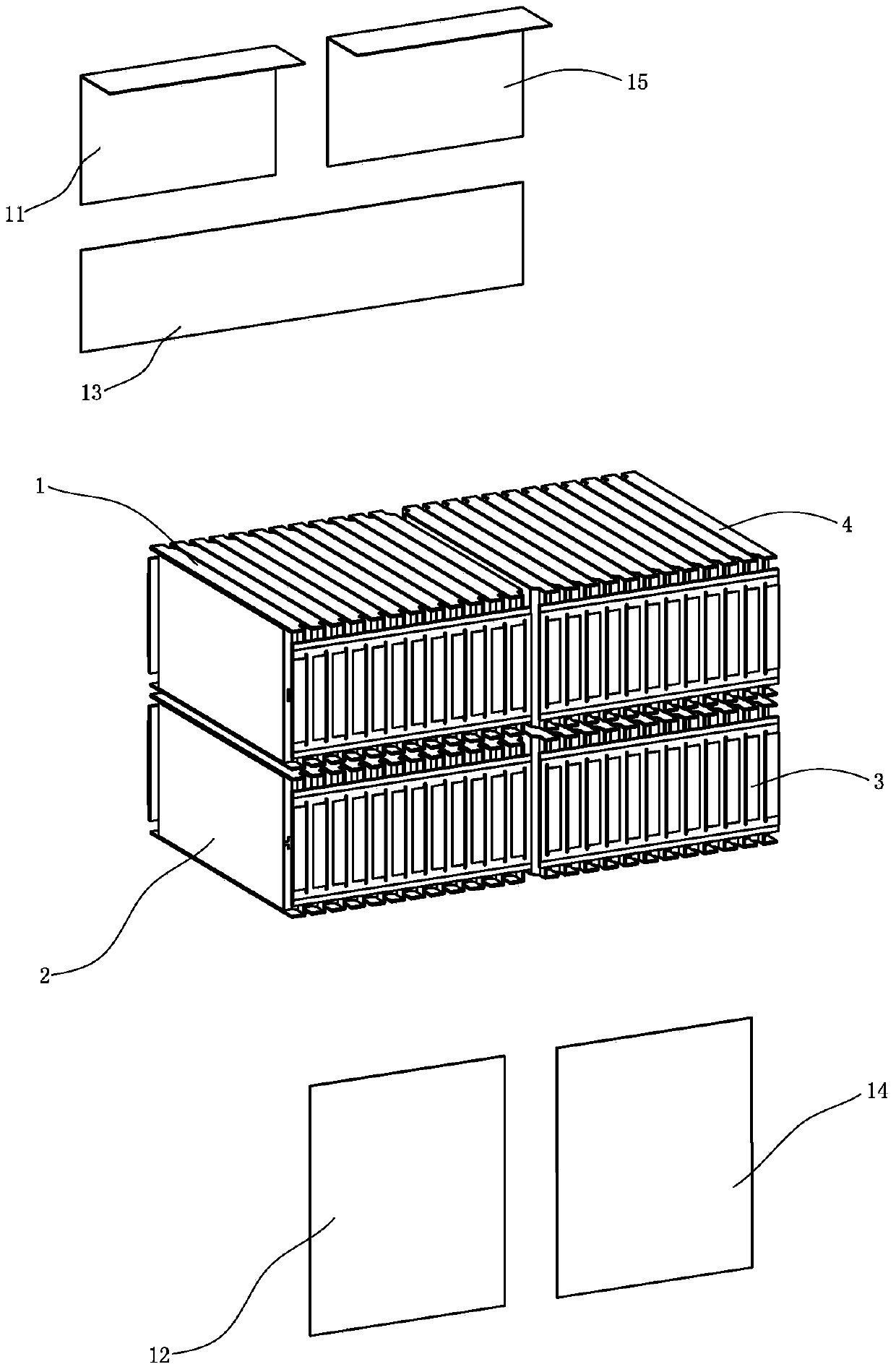

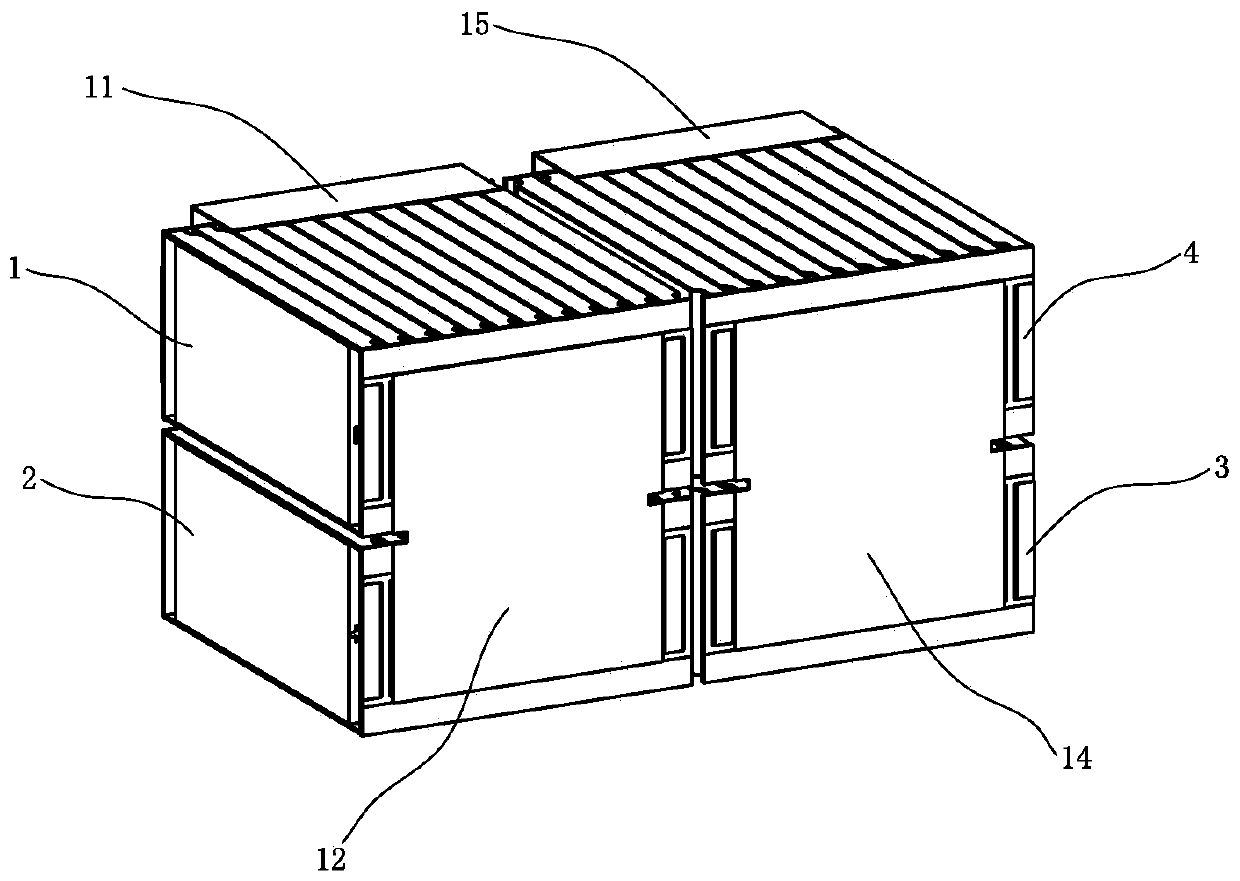

[0037] Such as Figure 1-5 The automobile lithium-ion starting battery shown is composed of a bracket and 4 cell groups installed on the bracket. The 4 cell groups are distributed in upper and lower layers, and the cell groups are composed of multiple The battery core body 20 is stacked, and the positive and negative electrode handles of the battery core body are respectively arranged at the two ends of the battery core body.

[0038] The first cell group 1 and the fourth cell group 4 are located on the upper layer, and the second cell group 2 and the third cell group 3 are located on the lower layer; the first to fourth cell groups are arranged from top to bottom, and then From left to right, and finally from bottom to top. The positive pole of the first battery pack 1 is connected to the first conductor 11 as the positive pole of the battery, and the negative pole of the fourth battery pack 4 is connected to the fifth conductor 15 as the negative pole of the battery. The n...

Embodiment 2

[0043] Such as Figure 8-12 The difference between the starting battery shown in Example 1 and the starting battery in Example 2 is that the starting battery in Example 2 is composed of 8 battery packs, and the 8 battery packs are distributed in upper and lower layers. The first battery pack 1, The fourth cell group 4, the fifth cell group 5 and the sixth cell group 6 are located on the upper layer, the second cell group 2, the third cell group 3, the seventh cell group 7 and the eighth cell group 8 Located on the lower level.

[0044] The negative pole of the first battery pack 1 is on the same side as the positive pole of the second battery pack 2, and is connected with the second conductor 12; the negative pole of the second battery pack 2 is on the same side as the positive pole of the third battery pack 3, And connect with the third conductor 13; the negative pole of the third battery pack 3 and the positive pole of the fourth battery pack 4 are on the same side, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com