Electronic equipment antenna main reflector and preparation method thereof

A technology of electronic equipment and main reflector, applied in antennas, chemical instruments and methods, electrical components, etc., can solve the problems of poor antenna surface strength and poor reflection effect of the main reflector, and achieve good adhesion and easy processing technology. Precise, impact-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below in conjunction with the examples. If no specific conditions are indicated in the examples, it will be carried out according to the conventional conditions or the conditions suggested by the manufacturer.

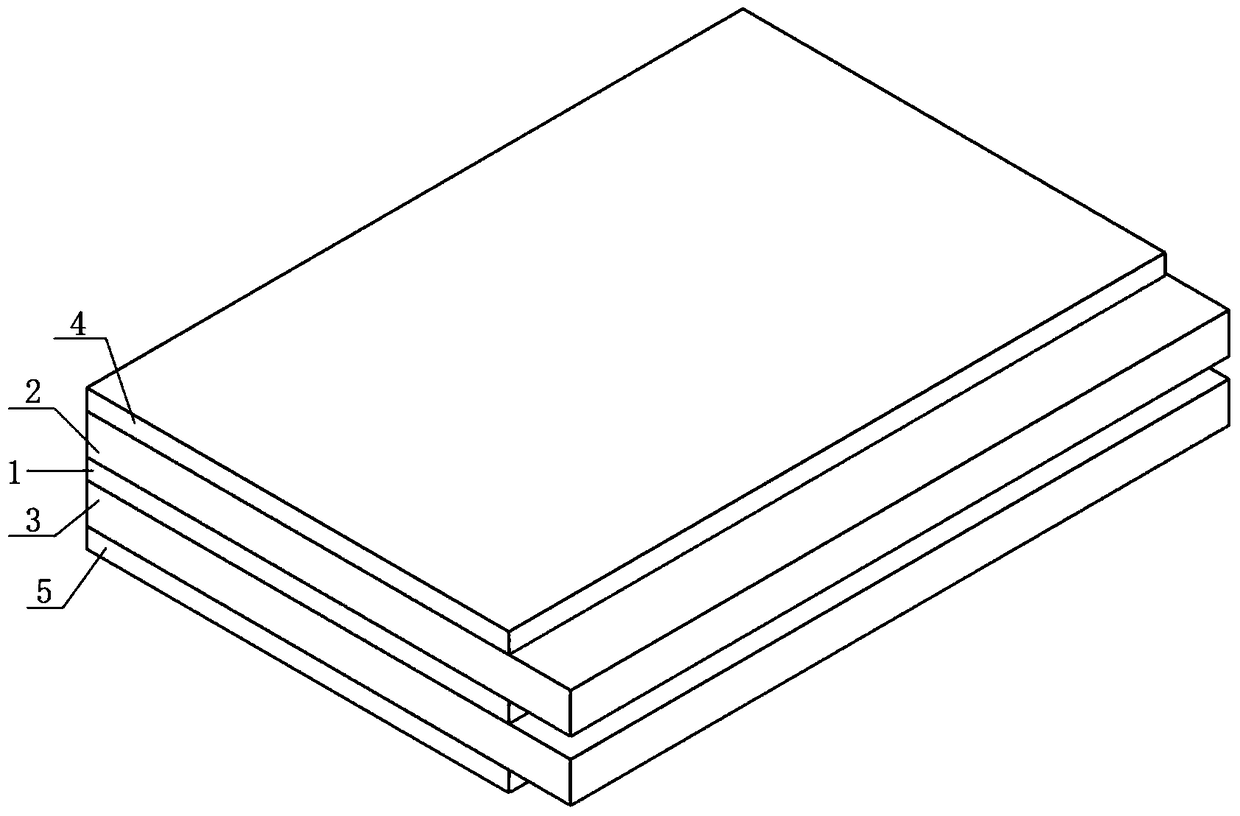

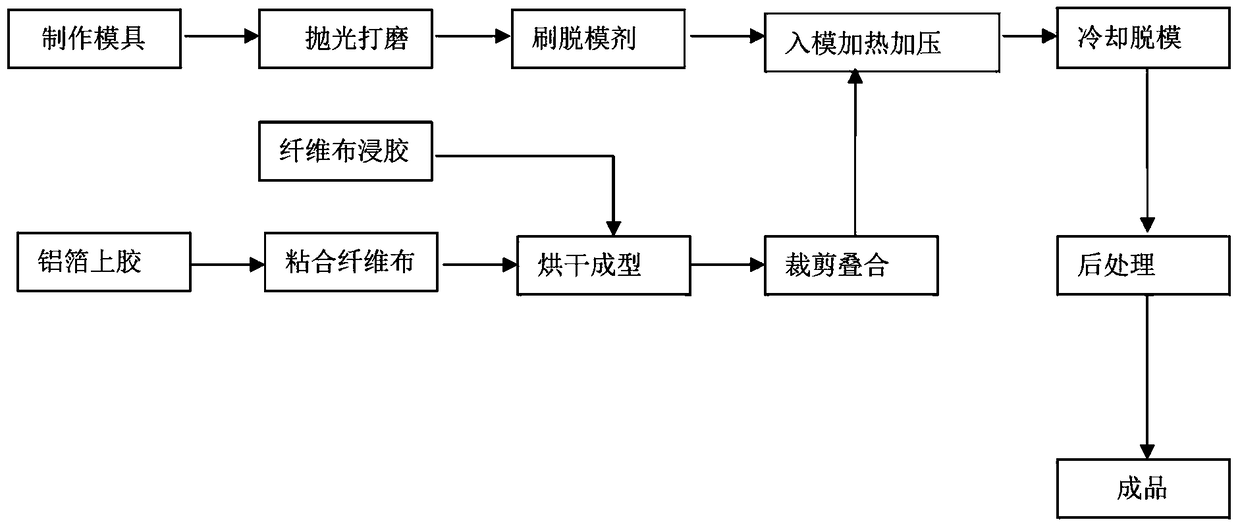

[0030] figure 1 The electronic equipment antenna main reflecting surface of an embodiment of the present invention is shown, which includes:

[0031] Aluminum foil cloth layer 1;

[0032] The first glass fiber cloth layer 2, the first glass fiber cloth layer 2 is bonded to one side of the plain weave aluminum foil cloth layer 1 with hot melt adhesive;

[0033] The second glass fiber cloth layer 3, the second glass fiber cloth layer 3 is bonded to the other side of the plain weave aluminum foil cloth layer 1 with hot melt adhesive;

[0034] The first unsaturated resin impregnated layer 4, the first unsaturated resin impregnated layer 4 is obtained by impregnating glass fiber cloth in the unsat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com