Automobile laminated glass capable of being uniformly and electrically heated

A technology of laminated glass and electric heating, applied in windshields, transparent/reflective heating devices, vehicle parts, etc., can solve the problems of voltage loss, inability to meet, poor heating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

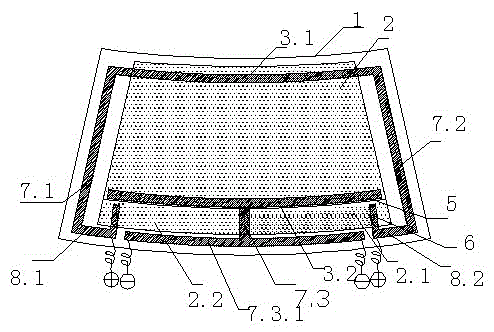

Embodiment 1

[0069] According to the present invention, a kind of automobile laminated glass capable of uniform electric heating is designed, which includes a glass substrate 1 and an electrothermal film layer 2, the electrothermal film layer 2 is coated on the glass substrate 1, and the peripheral edge of the electrothermal film layer 2 on the glass substrate 1 is provided with an edge In the non-conductive area, the upper bus bar 3.1 and the lower bus bar 3.2 are arranged on the electrothermal film layer 2, and a non-conductive dividing line 5 is provided near the bottom of the lower bus bar 3.2, which divides the electrothermal film layer 2 into the main viewing heating area and the heating at the static position of the wiper Area. Lay a first auxiliary busbar body part 7.3 through the wiper static position heating zone and the non-conductive dividing line 5 to divide the wiper static position heating zone into two areas 2.1 and 2.2 which are approximately mirror-image symmetric, the fir...

Embodiment 2

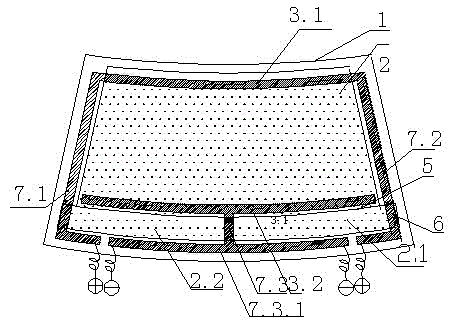

[0084] figure 2 gives something like figure 1 According to the structure, the heating zone at the rest position of the wiper is divided into two areas, which satisfy 4×N-2N and take a positive integer, so the second auxiliary bus can replace the third auxiliary bus. Others are the same as embodiment 1.

Embodiment 3

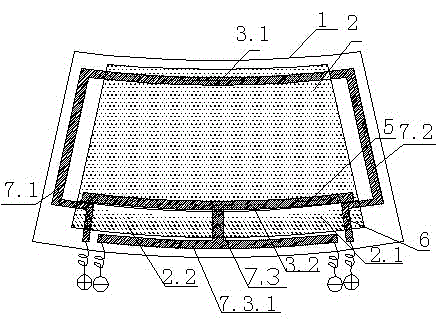

[0086] image 3In another way, the fourth auxiliary busbar can also be in the heating zone at the rest position of the wiper. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com