Especially mobile working machine and manufacturing method for vehicle concrete pump

A technology of concrete pump and working machine, applied in the field of concrete distribution rod, hinge point of support leg, and vehicle concrete pump, can solve the problems of limited stroke and inaccuracy of tools, and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

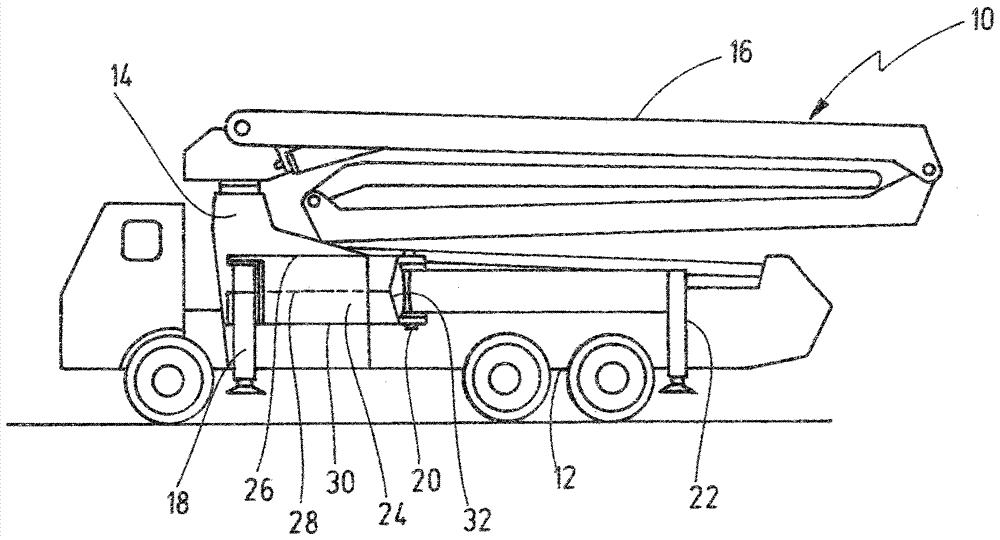

[0021] figure 1 The vehicle concrete pump 10 represented in includes a chassis 12, a load-bearing structure 14 mounted on the chassis and fixed to the vehicle, a concrete distribution rod 16 mounted on the load-bearing structure so as to be rotatable around a vertical axis of rotation, and two supports or rotating Legs 22 are each hinged to the load-bearing structure 14 via hinge points 20 and can be swiveled out about a vertical axis of rotation. The support legs 18, 20 can be moved out of the travel position shown into a support position further from the longitudinal axis of the vehicle.

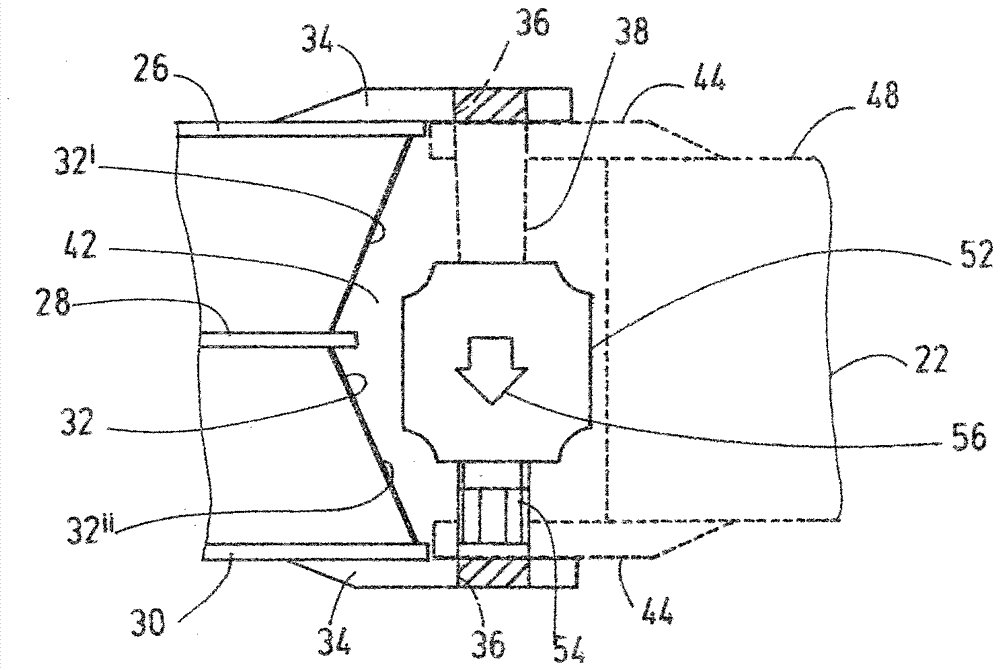

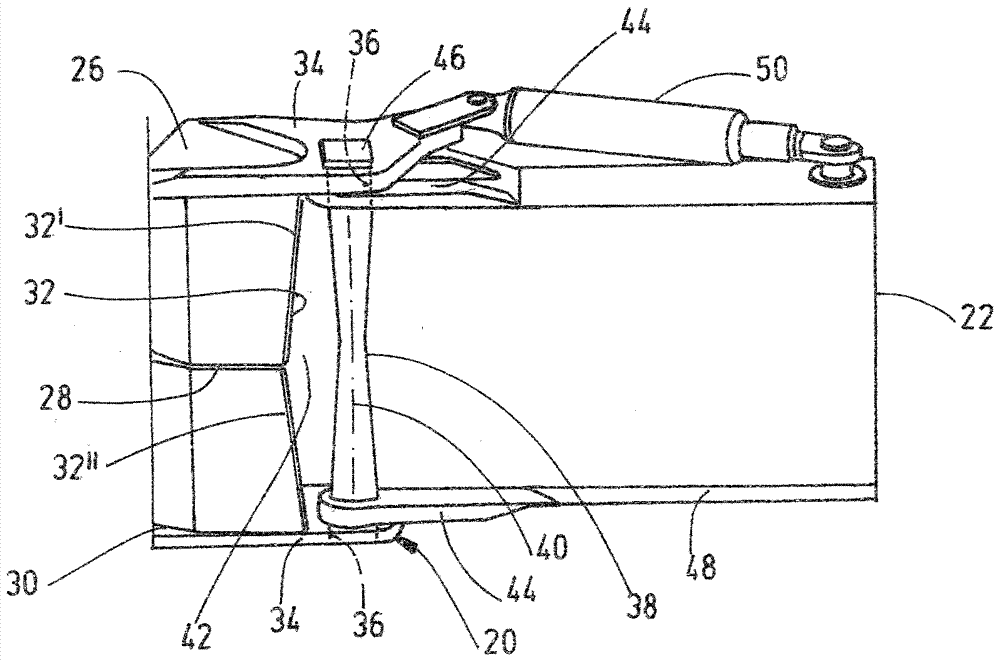

[0022] Each hinge point 20 is arranged at a box-type structure 24 consisting of three flanges 26, 28, 30 and wall panels welded thereto. In this case, the boundary wall 32 facing the hinge point 20 has a triangular hollow profile.

[0023] like figure 2 As best shown, the hinge points 20 each have two bearing plates 34 which are welded to the flanges 26 , 30 and which protrude above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com