A working method for fast and precise transfer of blocks

A working method and block technology, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyor objects, etc., can solve problems such as unsafe, low, and block damage, and achieve the effect of fast transfer and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

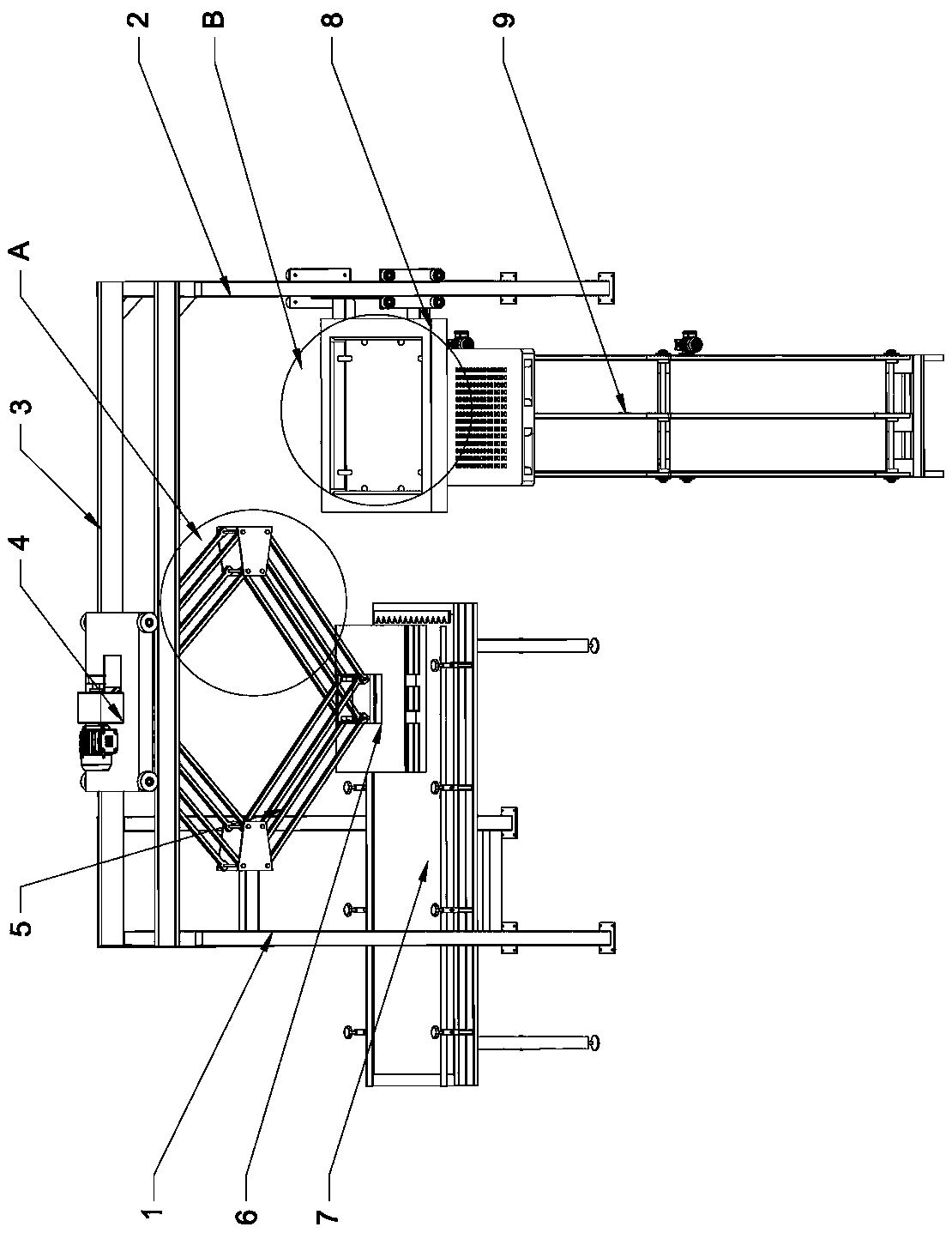

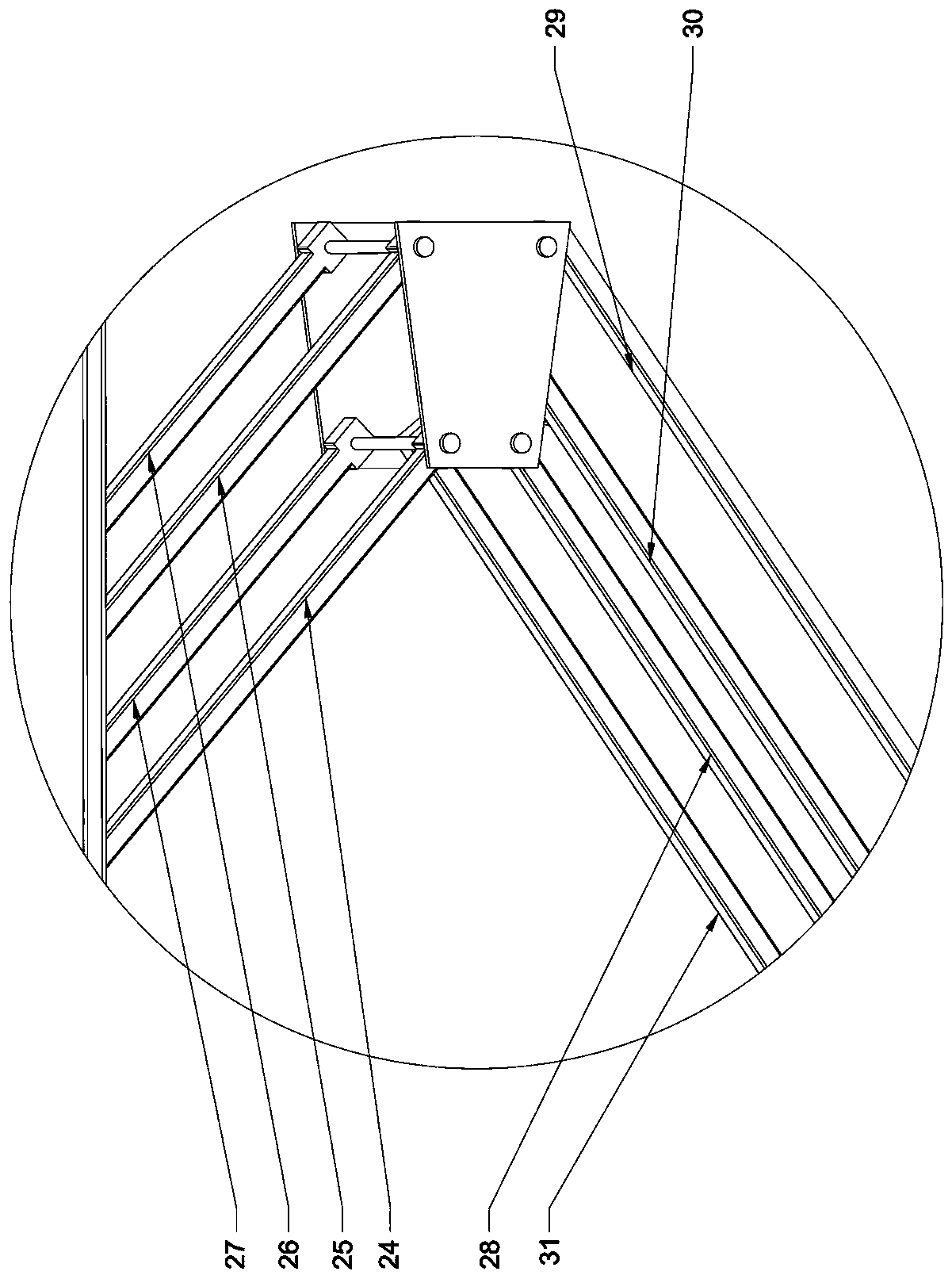

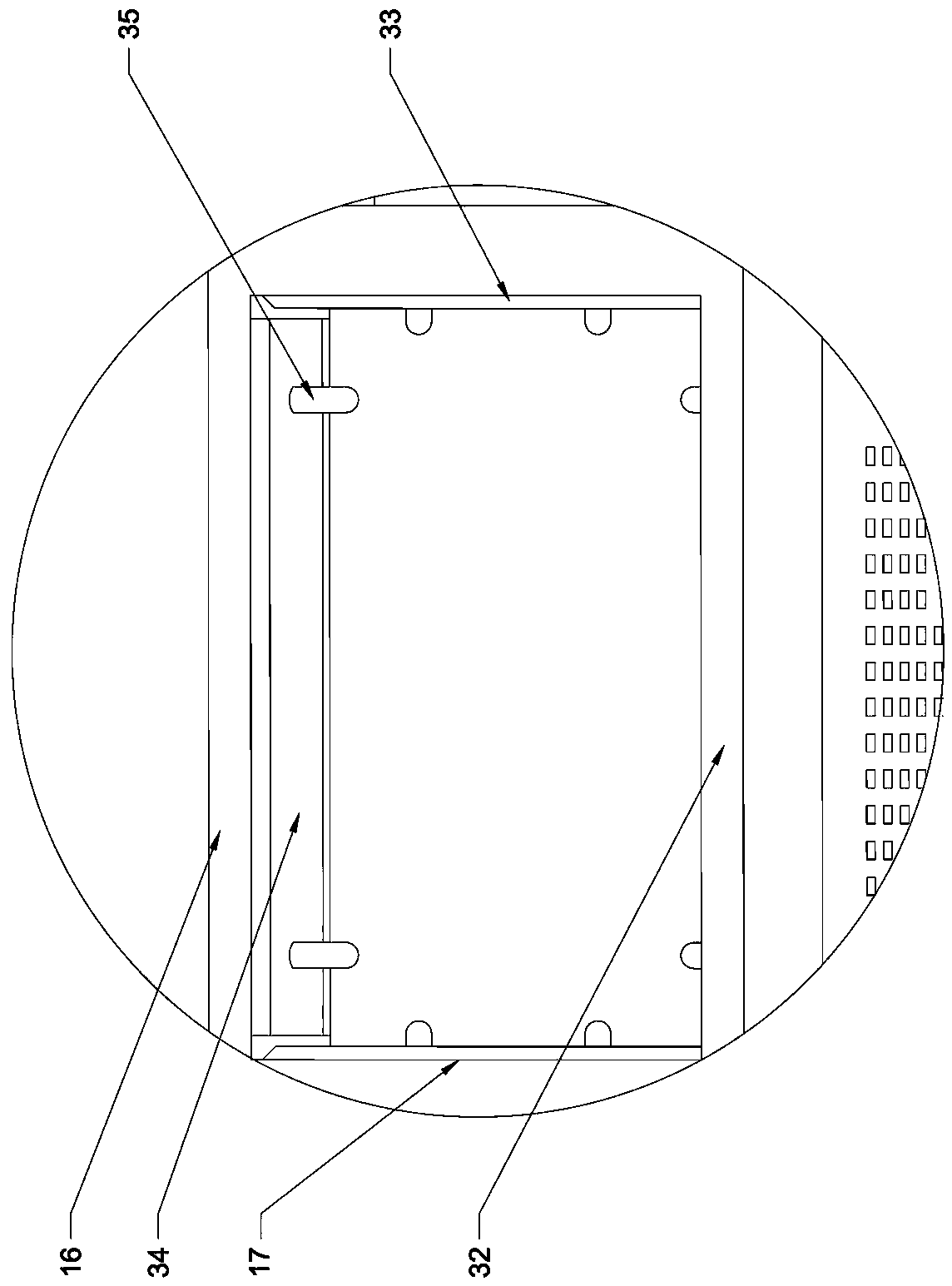

[0031] like Figure 1-8 As shown, the object of the present invention is achieved in the following way: a working method for fast and precise transfer of building blocks, including a left side support 1, a right side support 2 and its transverse track 3; Device 4. A control link assembly 5 is connected below the manipulator driving device 4, and a manipulator 6 is directly connected below the control link assembly 5; a finished block delivery device 7 and a finished block delivery device 7 are arranged below the transverse rail 3. Entry device 9; said right side bracket 2 is equipped with grab correction detection device 8 in cooperation with finished block entry device 9; it is characterized in that,

[0032] Including step 1, the operator firstly installs the main supporting frame, installs the transverse rail 3 on the left support 1 and the right support 2, uses the left translation device to translate the left support 1, and uses the right translation device to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com