Carbonation method of beverage

A carbonation and beverage technology, applied in chemical instruments and methods, mixing methods, chemical/physical processes, etc., can solve the problems of large absorption equipment, large space occupation, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

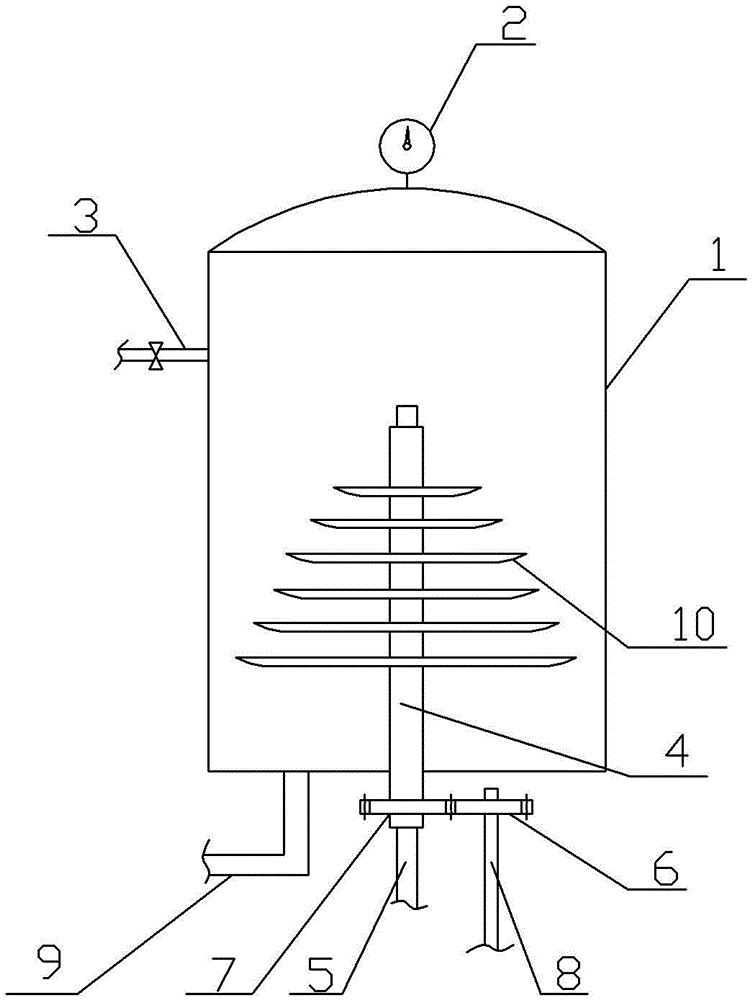

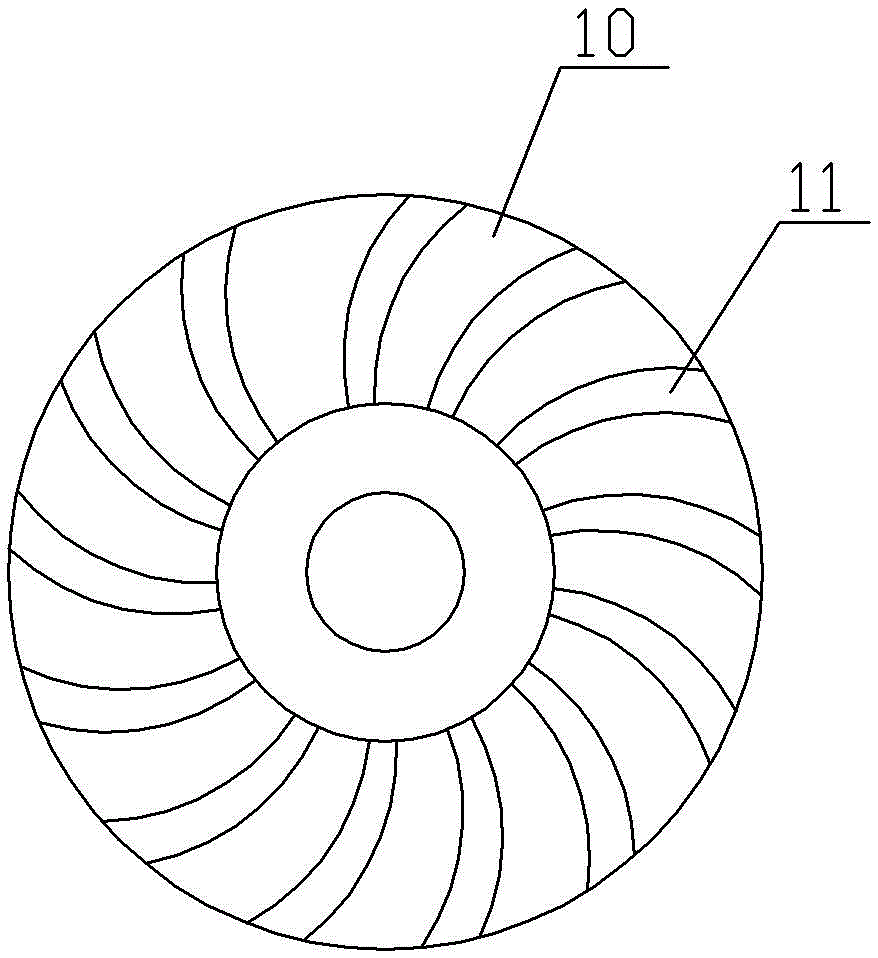

[0015] The reference signs in the drawings of the specification include: shell 1, pressure gauge 2, CO 2 Input pipe 3, rotating pipe 4, clean cold water pipe 5, driving gear 6, driven gear 7, transmission shaft 8, carbonated water outlet pipe 9, disc 10, splitter tank 11.

[0016] A kind of beverage carbonation method, relies on figure 1 , figure 2 The thin-film carbonation machine shown, the thin-film carbonation machine includes a casing 1, the casing 1 is a double-layer cylindrical structure composed of an outer cylinder and an inner cylinder, the outer cylinder is welded by steel plates, and the inner cylinder is a stainless steel gall. The interlayer between the inner cylinder and the outer cylinder is filled with heat insulating material, and the heat insulating material in this embodiment is airgel felt.

[0017] A pressure gauge 2 is installed on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com