Circumferentially-feeding and circumferentially-discharging flow assisting type sedimentation basin

A sedimentation tank and auxiliary flow technology, which is applied to the feeding/discharging device of the settling tank, the settling tank, etc., can solve the problems of large floor area and limited construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

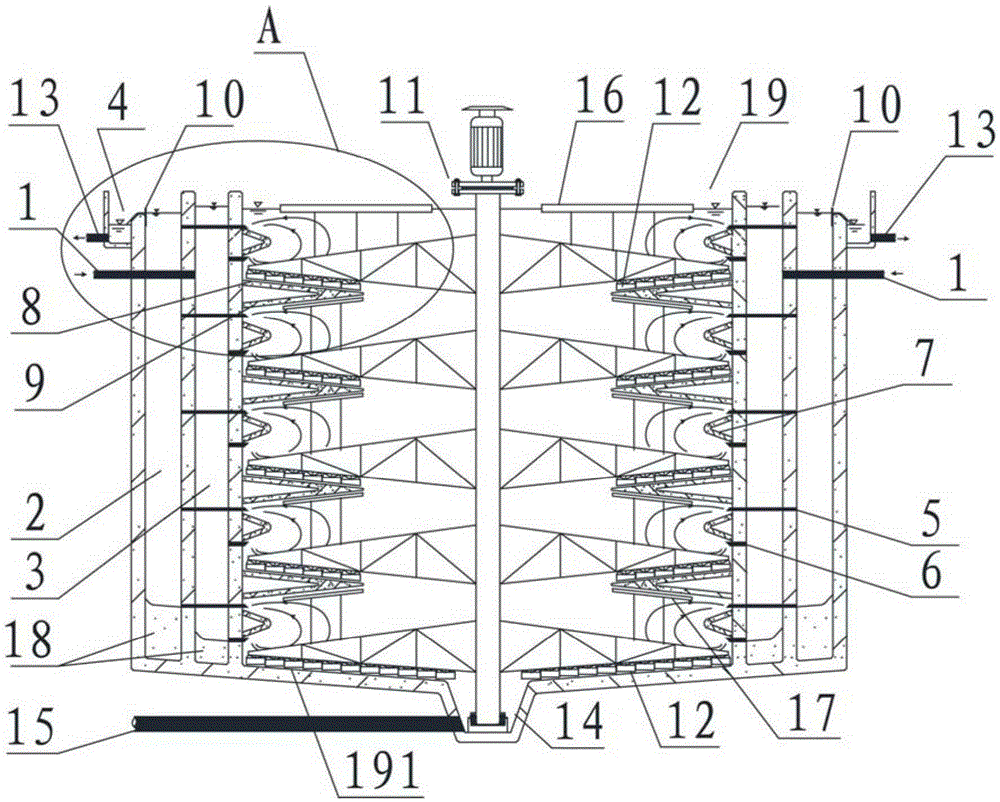

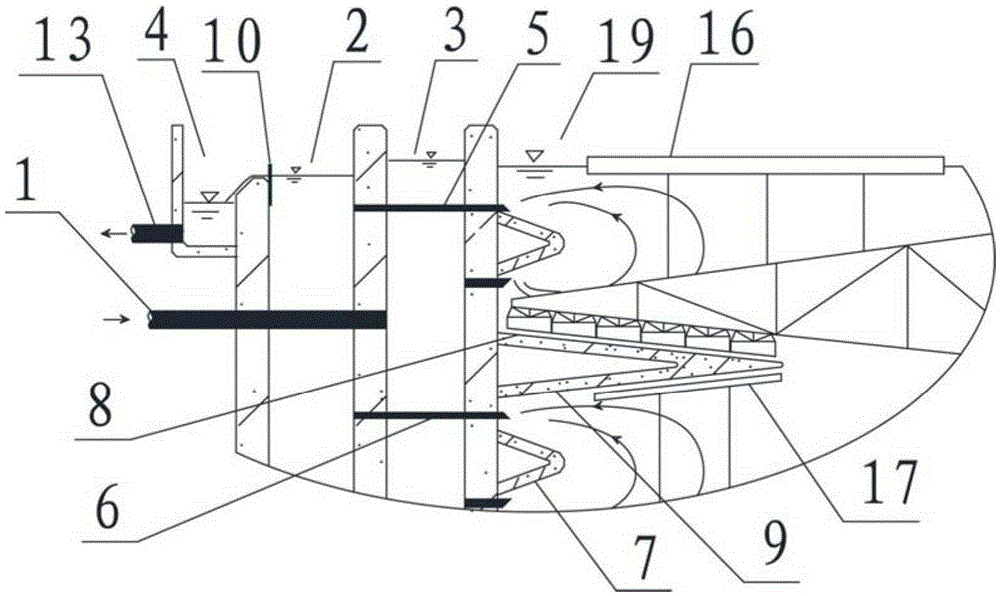

[0031] Such as figure 1 and 2As shown, the week-in and week-out auxiliary flow sedimentation tank provided by the embodiment of the present invention includes a tank body 19, a water distribution annular well 3, a water collection annular well 2 and a mud scraper and slag discharger 11, and the water distribution annular well 3 is arranged around the pool Outside the body 19, the water receiving annular well 2 rings are arranged on the outside of the water distribution annular well 3. Preferably, the diameter of the pool body 19 is 20m-30m, and the specific size is determined according to the calculation of the water volume, wherein the upper surface of the bottom of the pool body 19 is the bottom of the pool A sludge collection surface 191, the central area of the sludge collection surface 191 at the bottom of the pool is provided with a sludge bucket 14, and the bottom of the sludge bucket 14 is provided with a sludge discharge pipe 15 communicating with the outside of the...

Embodiment 2

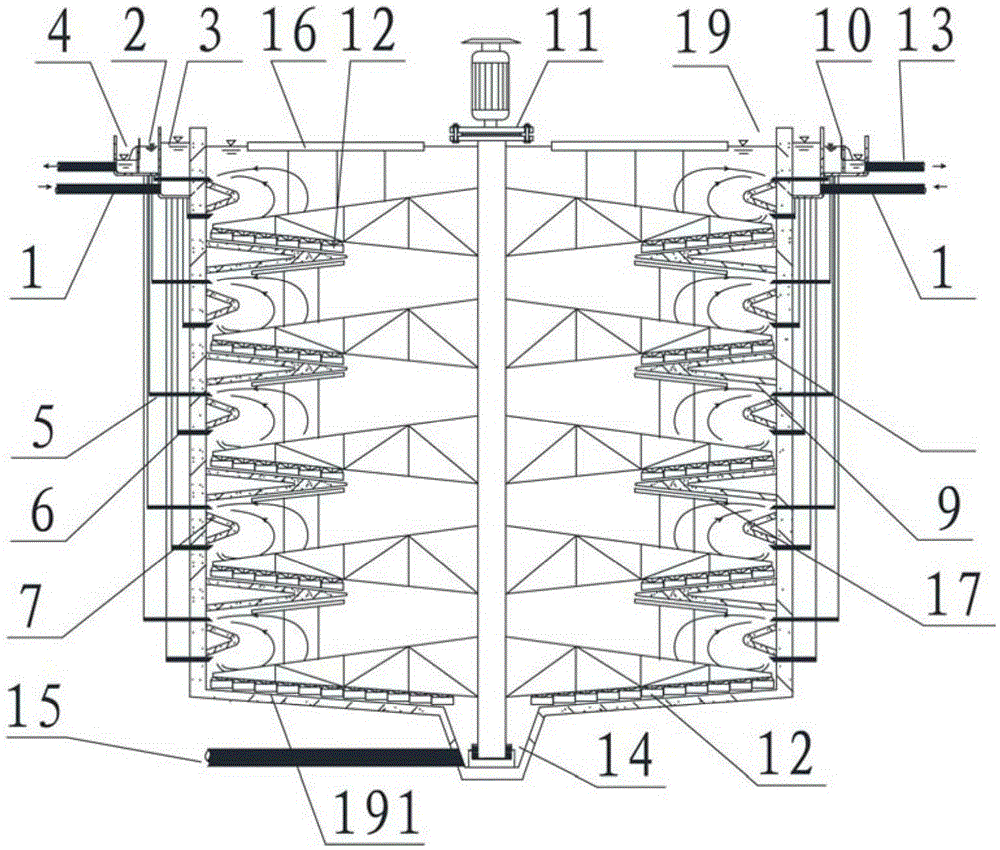

[0056] Such as image 3 As shown, the second embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that the depths of the water inlet and distribution annular well 3 and the water collection annular well 2 are reduced so that they are only arranged in the pool body 19 The top position is in the shape of a channel, and the pipes with the same diameter as the water inlet distribution pipe 6 and the water collection pipe 6 are used at the bottom to connect with the corresponding water inlet distribution pipe 6 and the water collection pipe 6 respectively, so as to reduce the amount of reinforced concrete in the pool body , reduce the cost of the tank body, and can further reduce the area of the sedimentation tank and save the area occupied by the sedimentation tank. This embodiment is especially suitable for regions where the climate is warm and does not freeze in winter.

[0057] In summary, the week-in and week...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com