Composite material prepared from active carbon and used for adsorption, and preparation method thereof

A technology of activated carbon preparation and composite material, applied in the field of water treatment, can solve problems such as desorption and secondary pollution, and achieve the effects of high adsorption capacity, stable adsorption and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

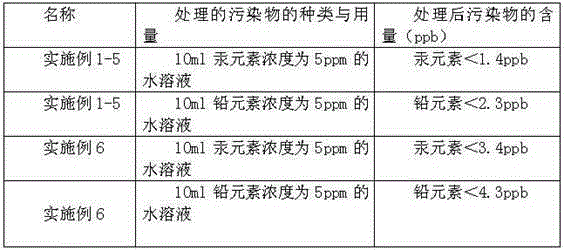

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a composite material prepared by activated carbon for adsorption is composed of the following raw materials in parts by weight: 21 parts of adhesive, 6 parts of transition metal compound, 13 parts of carbonitride, 13 parts of activated carbon, 5 parts of nickel nitrate Parts, 5 parts of tetrabutyl titanate, the above-mentioned composite material prepared by activated carbon for adsorption, is characterized in that it consists of the following steps: the transition metal compound, activated carbon and tetrabutyl titanate are pulverized by a pulverizing device, and then stirred The device makes it fully mixed, passes through a 100-mesh sieve to prepare mixture A, mixes the adhesive, nickel nitrate and carbonitride, mixes it with distilled water in a ratio of 1:1, and then performs ultrasonic treatment on it. The ultrasonic treatment condition is : temperature 50°C, ultrasonic power 400W, ultrasonic time 50min; prepare mixture B, ...

Embodiment 2

[0020] A composite material prepared by activated carbon for adsorption, consisting of the following raw materials in parts by weight: 22 parts of adhesive, 7 parts of transition metal compound, 14 parts of carbon nitrogen compound, 12 parts of activated carbon, 4 parts of nickel nitrate, tetrabutyl titanate 4 parts of ester. The preparation process is the same as in Example 1.

Embodiment 3

[0022] A composite material prepared by activated carbon for adsorption, consisting of the following raw materials in parts by weight: 23 parts of adhesive, 5 parts of transition metal compound, 10 parts of carbon nitrogen compound, 16 parts of activated carbon, 7 parts of nickel nitrate, tetrabutyl titanate 2 parts of ester. The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com