Dry-wet mixed type electrostatic precipitator and working method thereof

An electrostatic precipitator, a hybrid technology, applied in the direction of chemical instruments and methods, electrostatic separation, electrostatic effect separation, etc., can solve problems such as no successful cases, electric field failure, incomplete dust removal, etc., to prevent backflow of flue gas and ensure The effect of reliability and service life, saving materials and processing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

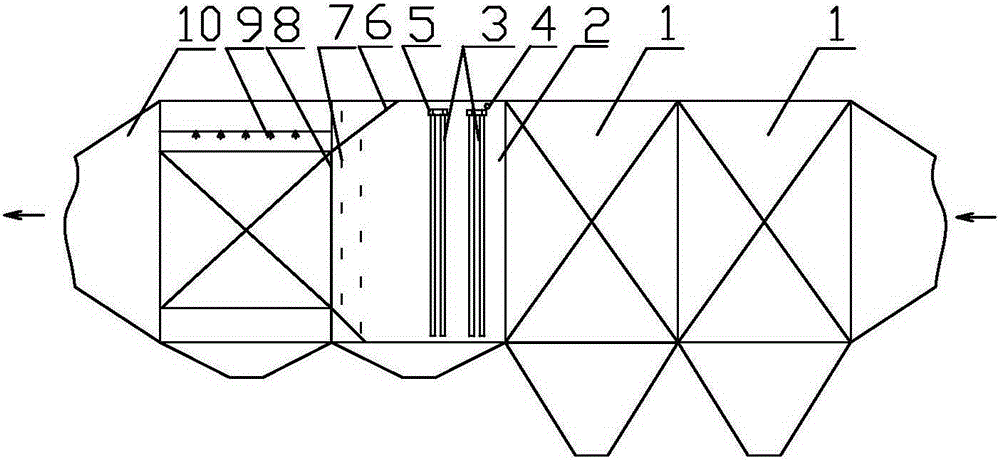

[0043] Such as figure 1 shown. The dry-wet hybrid electrostatic precipitator includes a shell, and the two ends of the shell are respectively provided with a smoke inlet and a smoke outlet. The end of the shell near the smoke inlet is provided with a dry dust removal electric field 1, and the inside of the shell is close to the smoke outlet. There is a wet dedusting electric field 10 at one end of one end, and a conversion area 2 for cooling and humidifying the flue gas is provided between the dry dedusting electric field 1 and the wet dedusting electric field 10. The characteristics of the flue gas and adjust the section of the electric field to meet the working requirements of the wet dust removal electric field 10.

[0044] figure 1 In , the direction of the arrow indicates the flow direction of the flue gas. Obviously, figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com