Full-automatic frame buckling molding production line

A fully automatic, production line technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as loose fit and low processing efficiency, achieve high production efficiency, good product effect quality, and facilitate high-efficiency and rapid production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below by embodiment the present invention will be further described. It should be understood that the methods described in the examples of the present invention are only used to illustrate the present invention, rather than to limit the present invention, and any simple improvement to the preparation method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

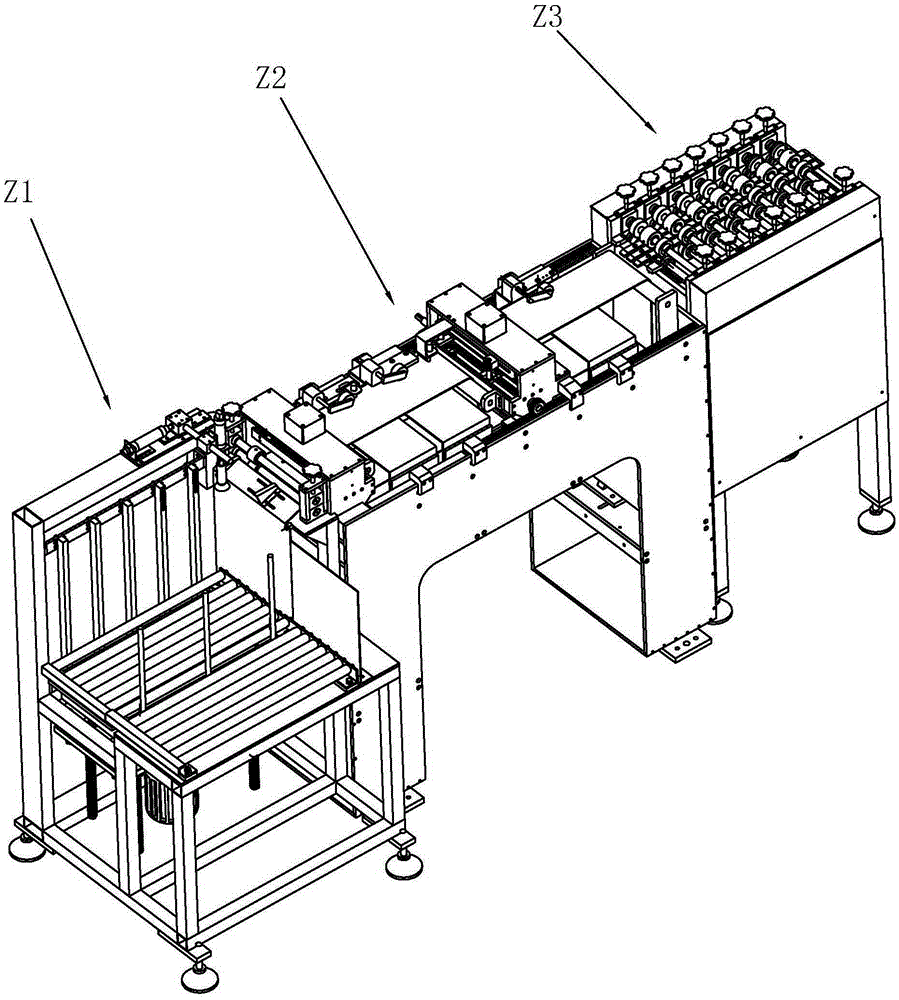

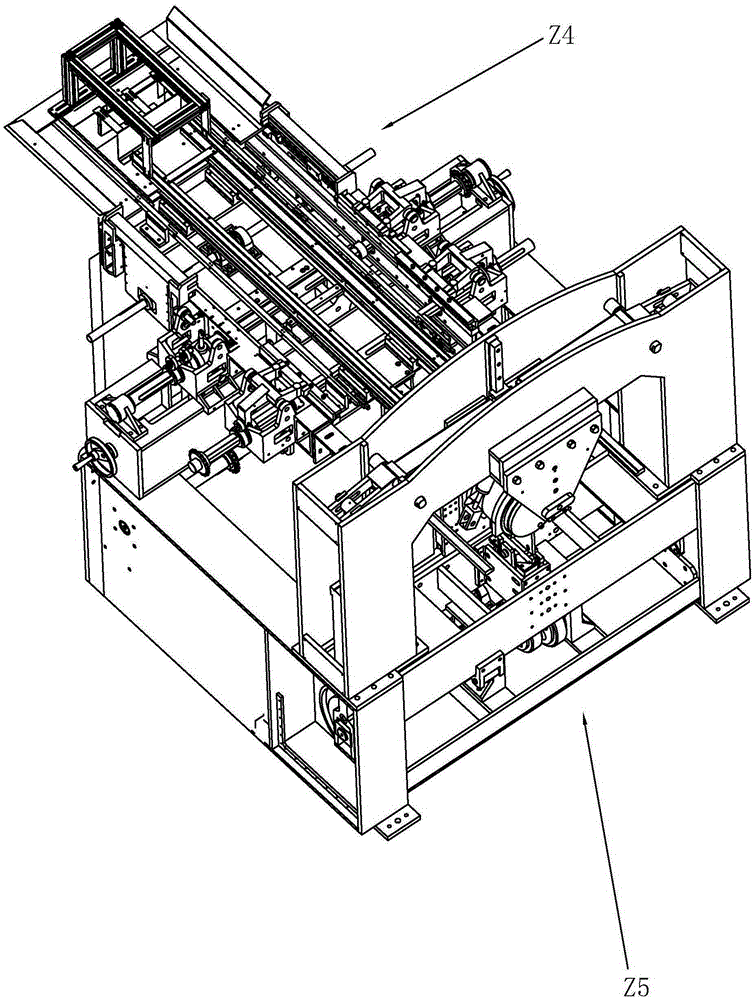

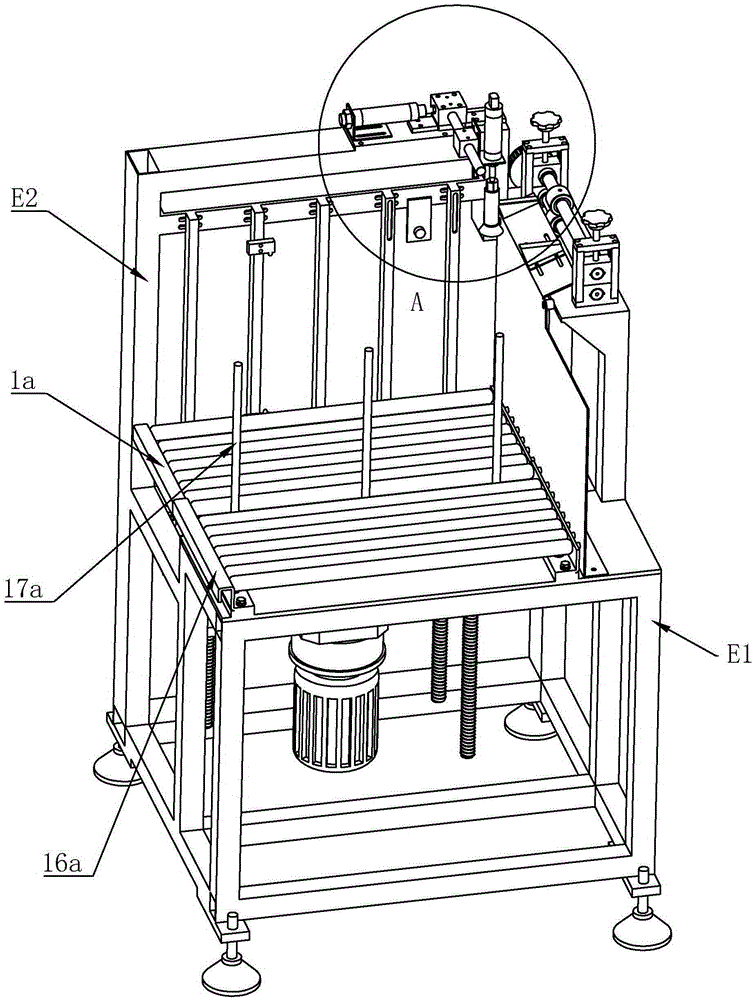

[0057] Refer to attached Figures 1 to 2 , the fully automatic buckle bone forming production equipment of the present invention includes a feeding device Z1, a cutting device Z2, a rolling device Z3, a transmission device Z4 and a buckle bone equipment Z5 connected in sequence, and the feeding device Z1 includes a The suction part and push sheet metal are sent to the push part of the cutting device Z2. The cutting device Z2 includes a punching mechanism and a conveyor belt 241. The punching mechanism cuts off the sheet metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com