Screw tightening machine capable of preventing screw from being brought up

A screw tightening machine and belt lifting technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as stability influence, limited application occasions, and increased control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

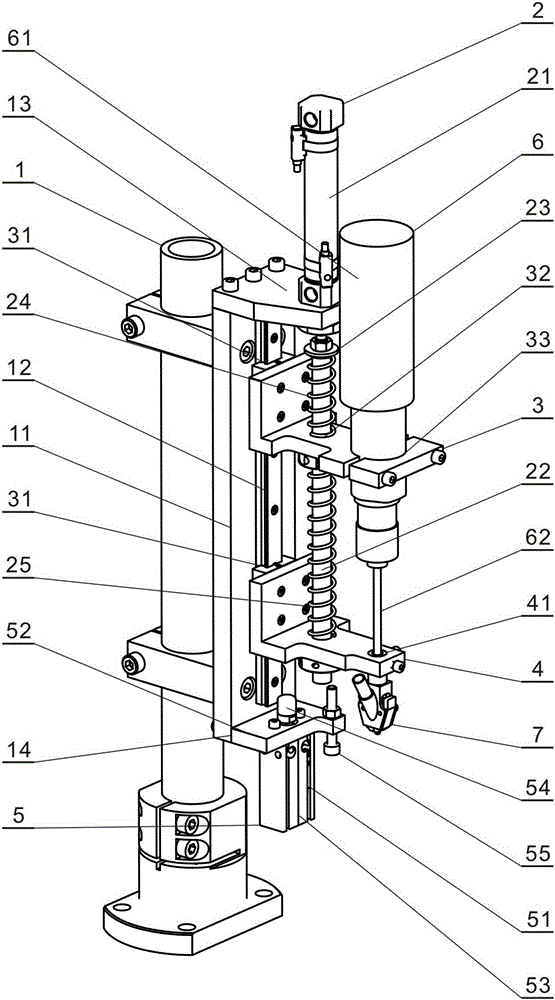

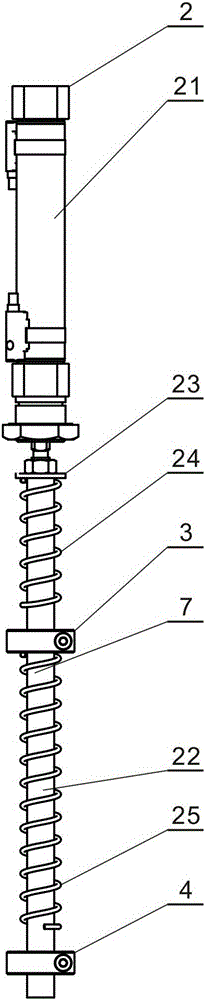

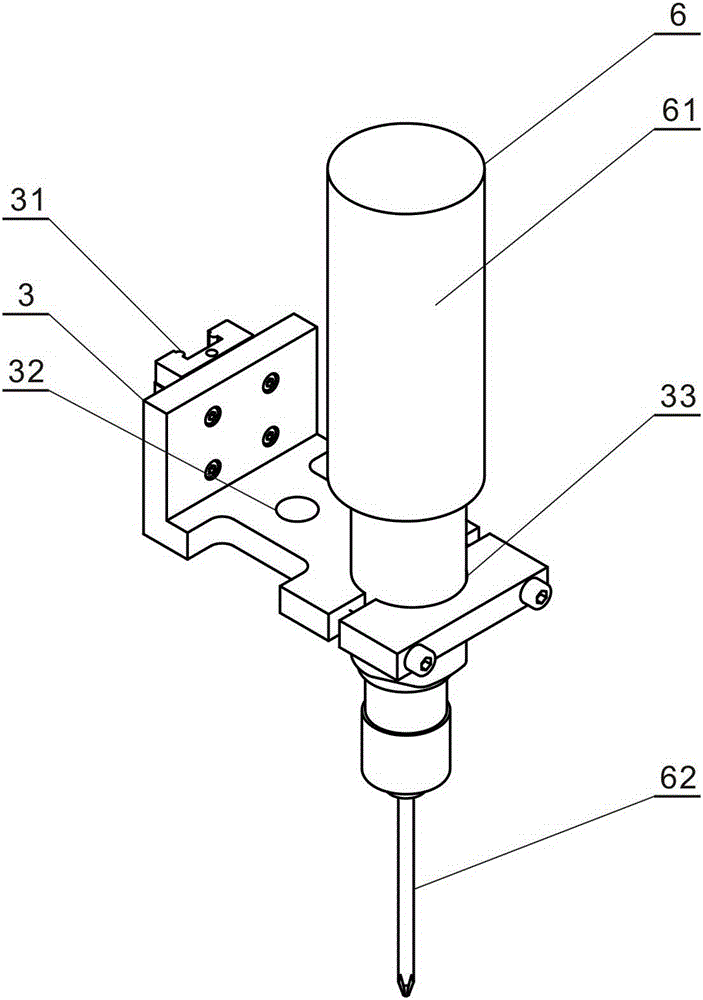

[0022] refer to figure 1 , figure 2 , Figure 7 , Figure 8 , the present invention adopts the PLC program control system to control the working procedures of each component in real time. The main points of work of the present invention are that when the batch knife 62 tightens the screw 9 on the product, the main cylinder 21 of the feed mechanism 2 drives the electric batch 61 of the upper slider 3, so as to maintain a stable axial contact between the batch knife 62 and the screw 9 When the batch knife 62 exits the screw 9, the jacking mechanism 5 drives the lower slider 4, prompting the batch head 7 to quickly disengage from the screw 9, and at the same time when the screw tightening work is completed, the hidden danger of the screw 9 being carried by the batch head is eliminated , to realize the non-contact pressure assembly between the present invention and the product 8.

[0023] Taking screw 9 screwed into the connector to implement product assembly as an example, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com