Multi-film heat seal cutting machine

A cutting machine and electric heating technology, which is applied in the field of medical and sanitary products production equipment, can solve the problems of product yield impact, high labor cost, easy wrinkling, etc., and achieve the effect of improving production precision, improving production efficiency, and high overlapping precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

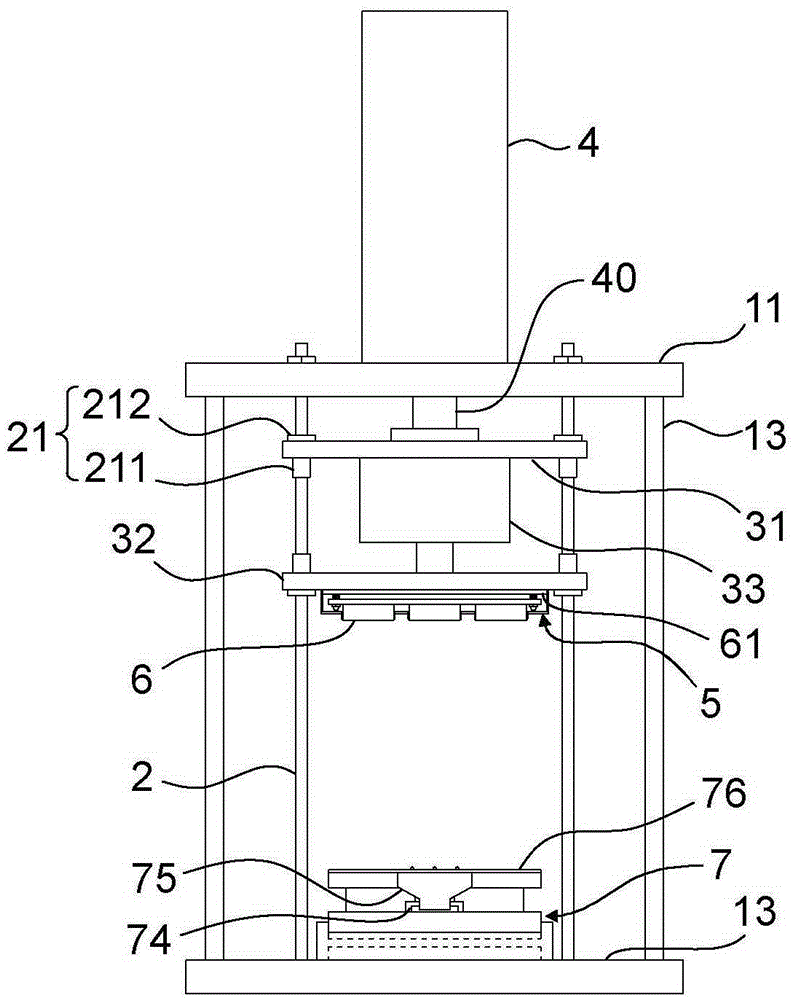

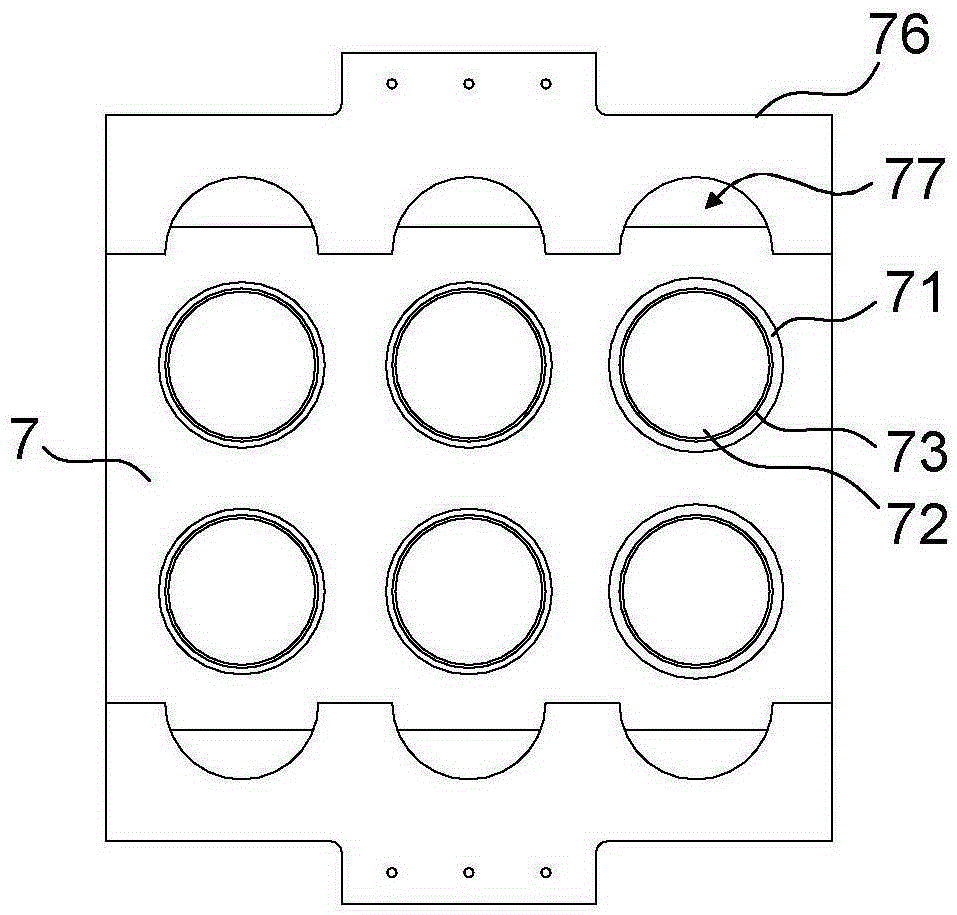

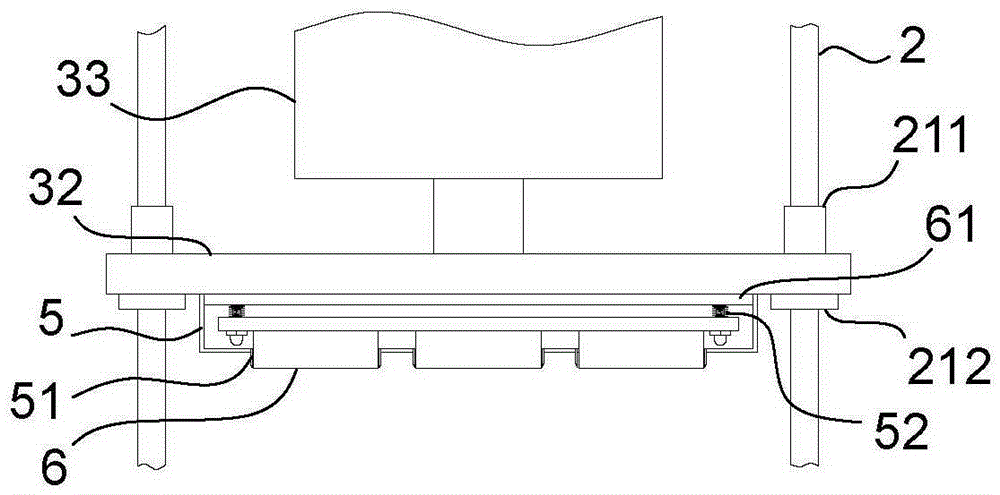

[0020] Such as Figure 1 to Figure 4 As shown, a multi-film heat-sealing cutting machine includes a bracket consisting of an upper cover 11, a base 12, and a column 13, a slide rail 2, an upper slide 31, a lower slide 32, a high-frequency electric heating device 33, a cylinder 4, and a cutting disc 5 , Cutter 51, elastic member 52, metal anvil 6, base plate 61, bottom plate 7.

[0021] The bracket is open on all sides, and the upper cover 11 and the base 12 are connected by four columns 13 around, and there are four cylindrical slide rails 2 connected to the upper cover 11 and the base 12 in the inner part, and on the slide rail 2 from top to bottom An upper slide plate 31 and a lower slide plate 32 are arranged below, and a high-frequency electric heating device 33 is fixed between the upper slide plate 31 and the lower slide plate 32 . The thermally conductive meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com