Partition power supply system for managing stray current at railway vehicle depot and control method

A subway depot, stray current technology, applied in vehicle components, power lines, transportation and packaging, etc., can solve problems such as arcing and ignition, and achieve the effect of aggravating leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

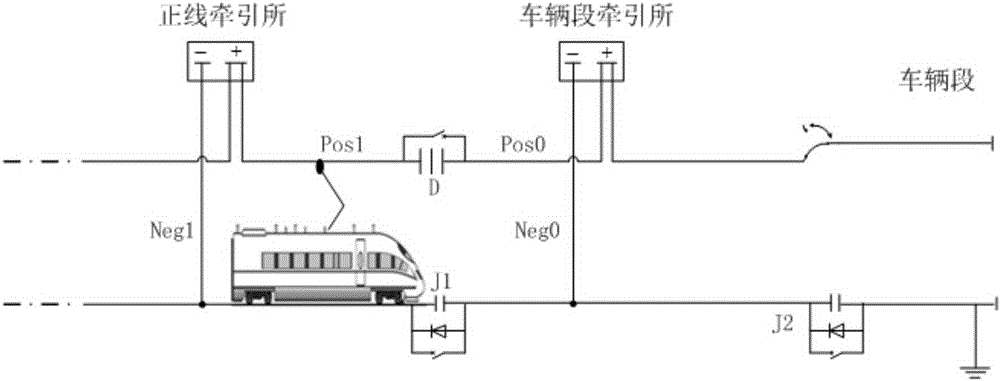

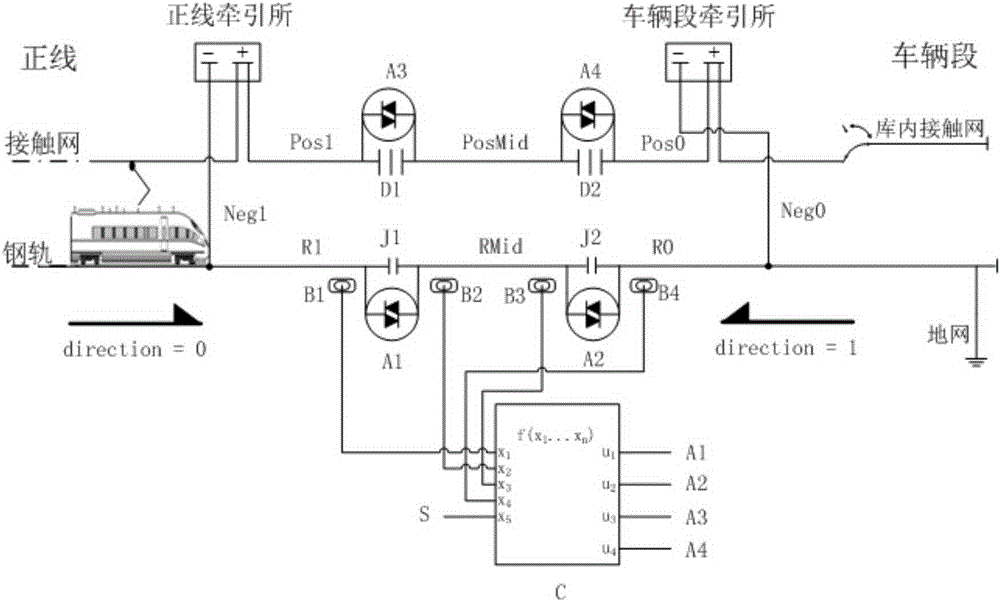

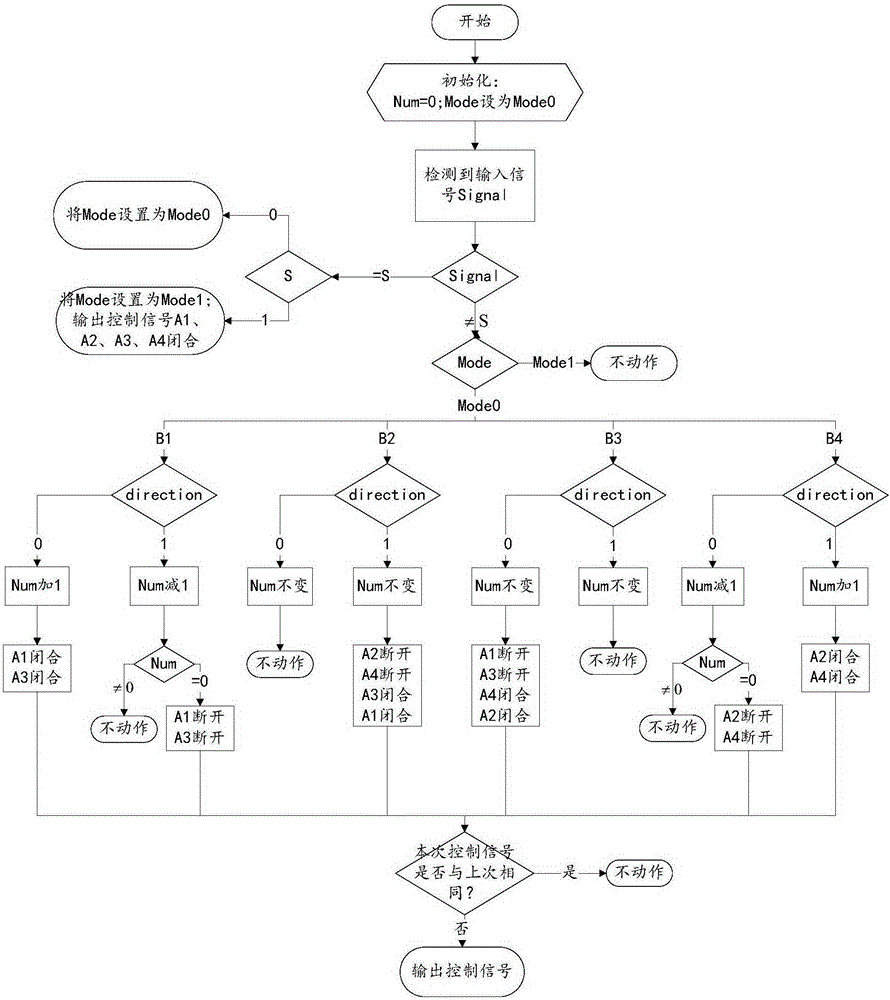

[0027] Such as figure 2As shown, the present invention includes insulation joint J (including J1, J2), catenary electrical segment D (including D1, D2), high-power DC thyristor switch A (including A1, A2, A3, A4), track axle counter B (including B1, B2, B3, B4), state identification control unit (C), depot power supply system operation status signal (S), characterized in that: two insulating joints J1, J2 are set between the depot and the main line , the distance between which is greater than 1.5 times the length of the train, cancel the one-way conduction device in parallel with J1 and J2 in the existing scheme, and connect A1 and A2 in parallel at both ends of J1 and J2 respectively, and the track area on the main line side of J1 is R1, J1, J2 The track area between them is RMid, and the track area on the J2 depot side is R0; catenary subsections ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com