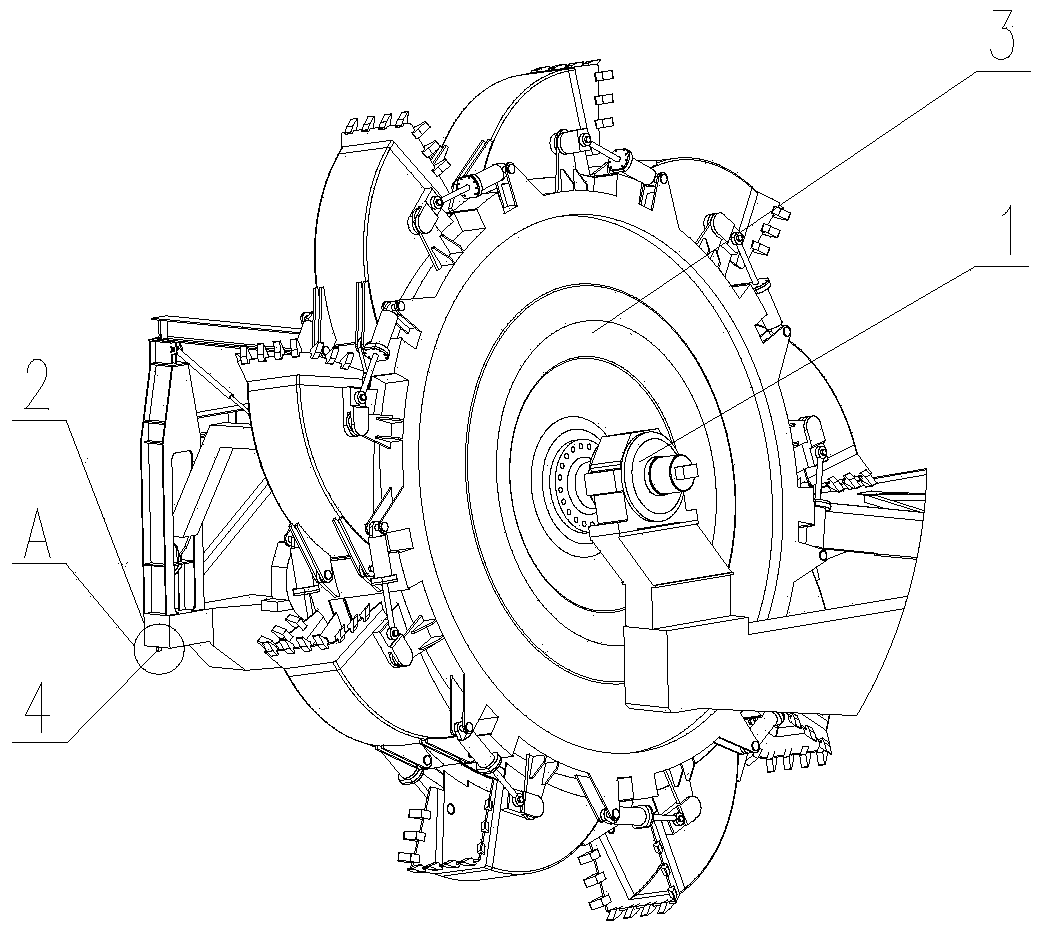

A retractable yard self-adaptive flexible bucket wheel device

An adaptive, bucket-wheel technology, applied in transportation and packaging, loading/unloading, mechanically driven excavators/dredgers, etc., can solve the problems of rigid collision and inability to clear the yard, and achieve the goal of reducing the cost of clearing the yard Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

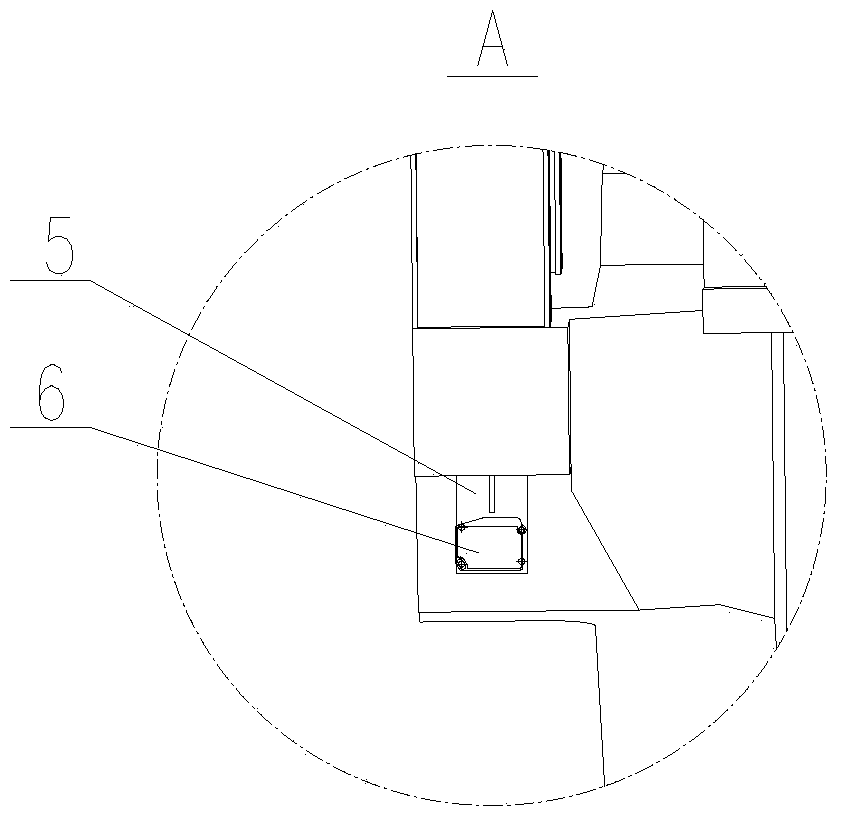

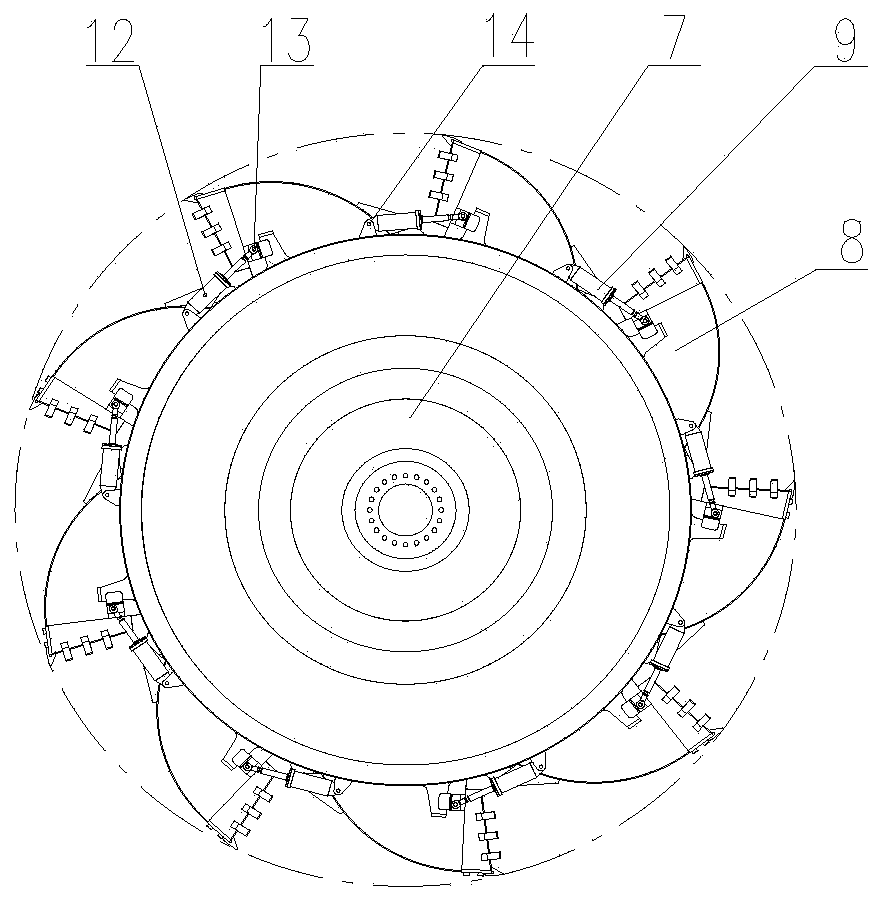

[0050] In the first embodiment, during the normal reclaiming and material lifting process of the hopper 8, the digging resistance, material gravity and the self-weight of the hopper 8 acting on the hopper 8 are borne by the hopper outer limit baffle 27 of the bucket wheel body 7, and the spring pressing rod 37 In the initial state, the hopper 8 is in a rigidly open state without being subjected to tension and pressure; during the unloading and no-load operation of the hopper 8, the spring pressure rod 37 is pressed by the gravity of the hopper 8, and the cylindrical spring retracting device 9 The initial pre-pressure is greater than the pressure of the spring pressing rod 37 under the action of the self-weight of the hopper 8, the self-weight of the hopper 8 cannot push the spring pressing rod 37 to move in the axial direction, the cylindrical spring 35 is still in the pre-compressed state, and the spring pressing rod 37 is always in the initial state , the hopper 8 is in a sem...

Embodiment 2

[0054] In the second embodiment, during the normal reclaiming and material lifting process of the hopper 8, the digging resistance, material gravity and the self-weight of the hopper 8 acting on the hopper 8 are borne by the hopper outer limit baffle 27 of the bucket wheel body 7. At this time, the plate The spring retracting device 10 is in the initial state and does not bear tension and pressure, and the hopper 8 is in a rigidly open state; during the unloading and no-load operation of the hopper 8, the head of the leaf spring retracting device 10 is under the action of the gravity of the hopper 8. Under pressure, the initial pre-pressure of the leaf spring retracting device 10 is greater than the pressure generated by the leaf spring retracting device 10 under the action of the self-weight of the hopper 8, and the self-weight of the hopper 8 cannot compress the leaf spring retracting device 10 to move inward, and the leaf spring returns The retracting device 10 is in the ini...

Embodiment 3

[0057] In the third embodiment, the bucket wheel body 7 is the same as the bucket wheel body 7 in the first embodiment.

[0058] In the third embodiment, during the normal reclaiming and material lifting process of the hopper 8, the digging resistance, material gravity and the self-weight of the hopper 8 acting on the hopper 8 are borne by the hopper outer limit baffle 27 of the bucket wheel body 7, and the hydraulic pressure rod 40 In the initial state, and does not bear tension and pressure, the hopper 8 is in a rigidly open state; during the unloading and no-load operation of the hopper 8, the hydraulic pressure rod 40 is pressurized by the gravity of the hopper 8, and the nitrogen in the air bag 37 is pressed. 39 The pressure is greater than the pressure of the hydraulic pressure rod 40 under the action of the self-weight of the hopper 8, the self-weight of the hopper 8 cannot push the hydraulic pressure rod 40 to move in the axial direction, the hydraulic pressure rod 40 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com