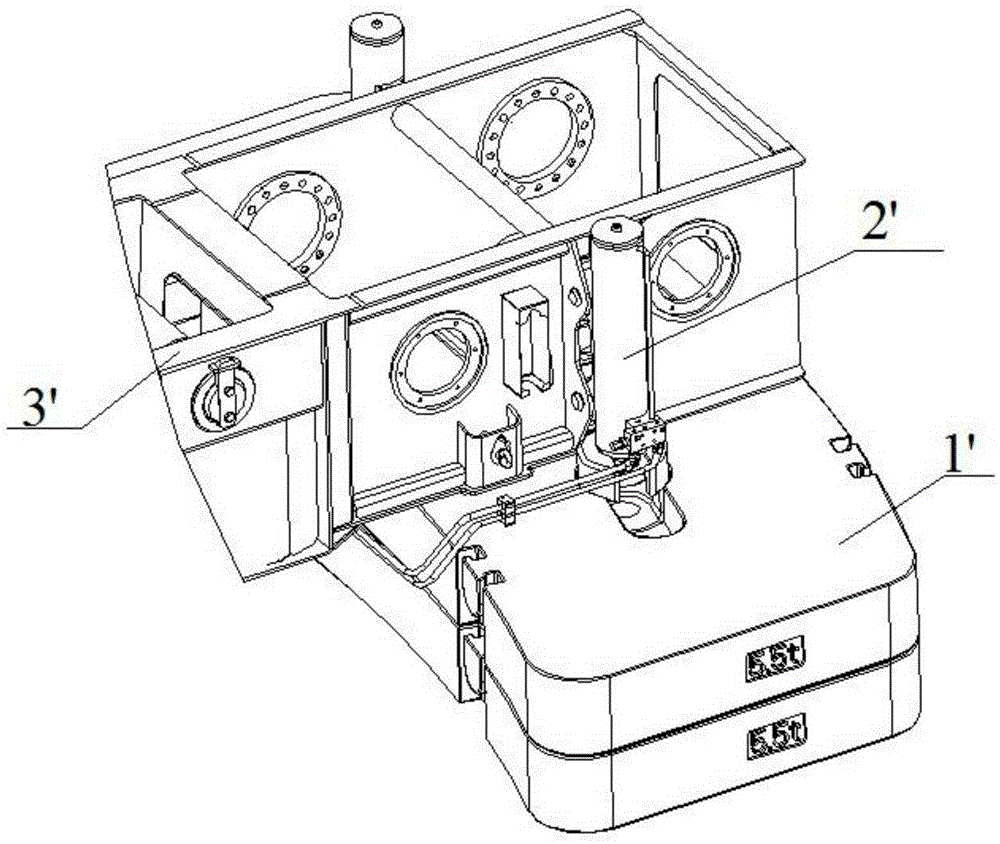

Balancing weight hitching device and crane

A technology of counterweight and connecting frame, which is applied in the direction of cranes, etc., can solve the problems of increasing hydraulic system cost, system complexity, energy loss, etc., and achieve the effects of low production and operation costs, streamlined operating system, and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

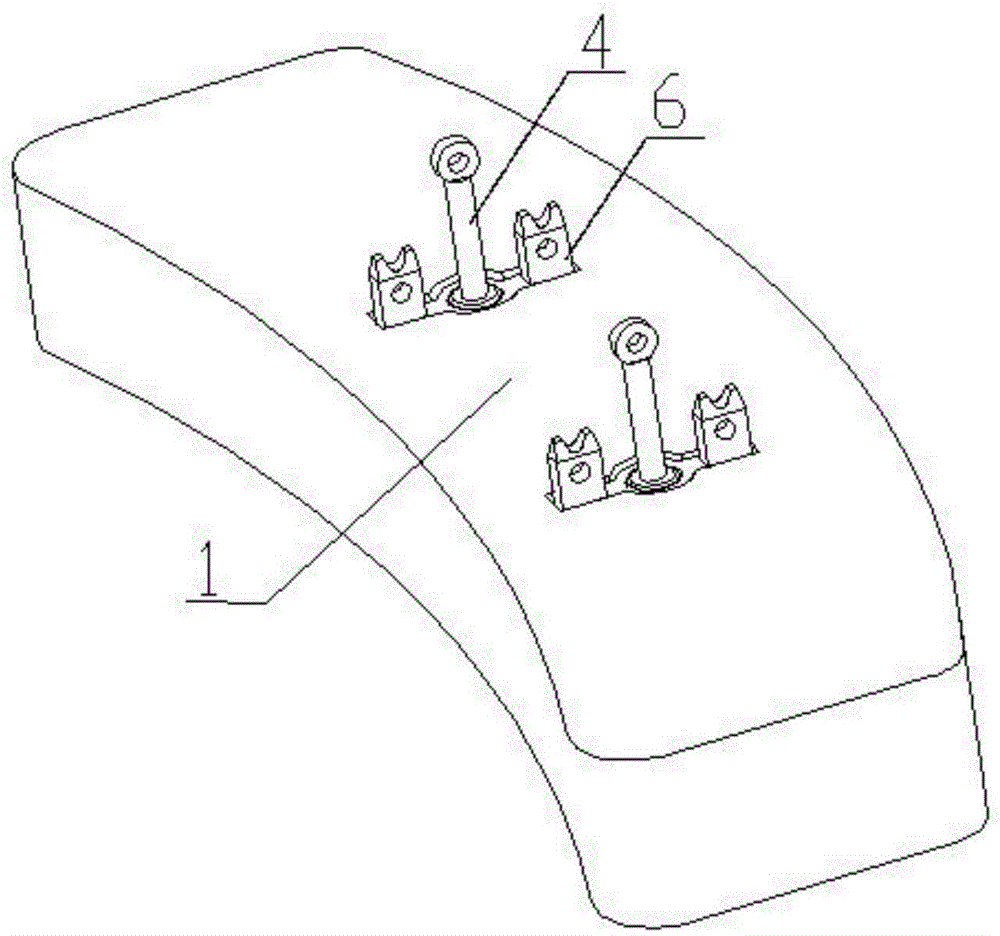

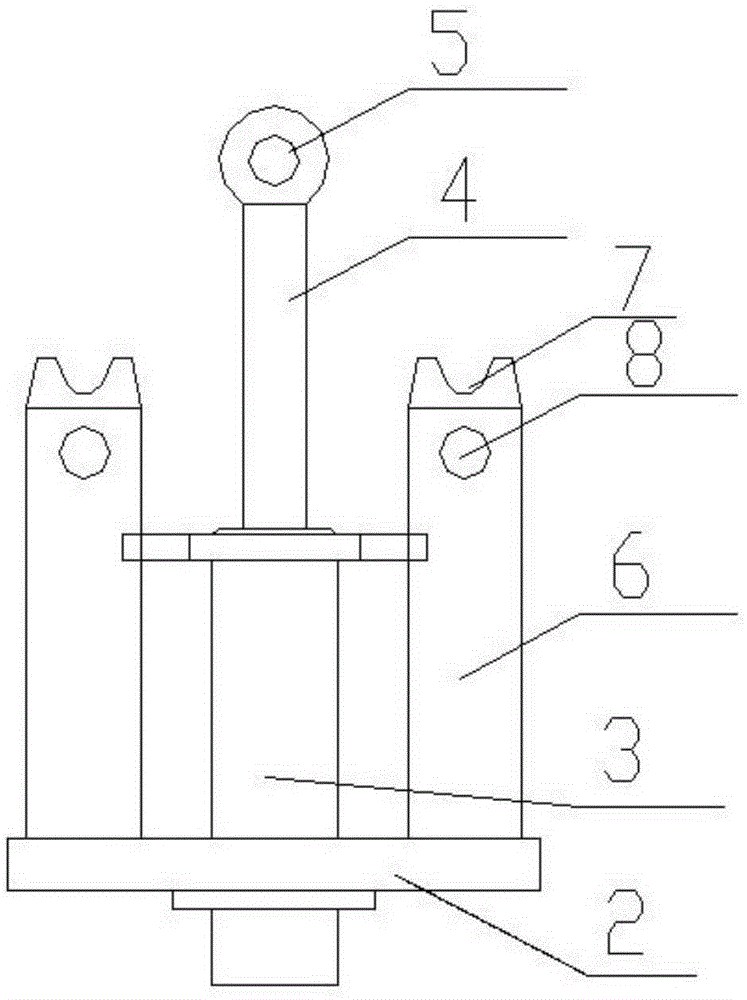

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0023] see figure 2 with image 3 , the balance weight hooking device of the present invention includes: a power source and a connecting frame assembly fixed in the balance weight 1, wherein the connecting frame assembly includes: a base 2 fixedly connected with the balance weight 1, a lifting mechanism installed on the base 2 And a pair of positioning mechanisms symmetrically arranged on both sides of the lifting mechanism. Wherein, the lifting mechanism includes: a lifting cylinder 3 and an articulated hole 5 formed at the free end of the cylinder rod 4 of the lifting cylinder, and a pair of positioning mechanisms both include: a guide articulated bracket 6 and a fixing hole 8 formed at the free end of the guide articulated bracket 6 .

[0024] During the hooking process, the power source is used to drive the lift cylinder rod 4 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com