A treatment device for catering wastewater

A treatment device and technology for catering wastewater, applied in the direction of flotation water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc. Unsatisfactory oil removal effect, etc., to improve the separation effect of floating oil, occupy a small space, and reduce the use of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

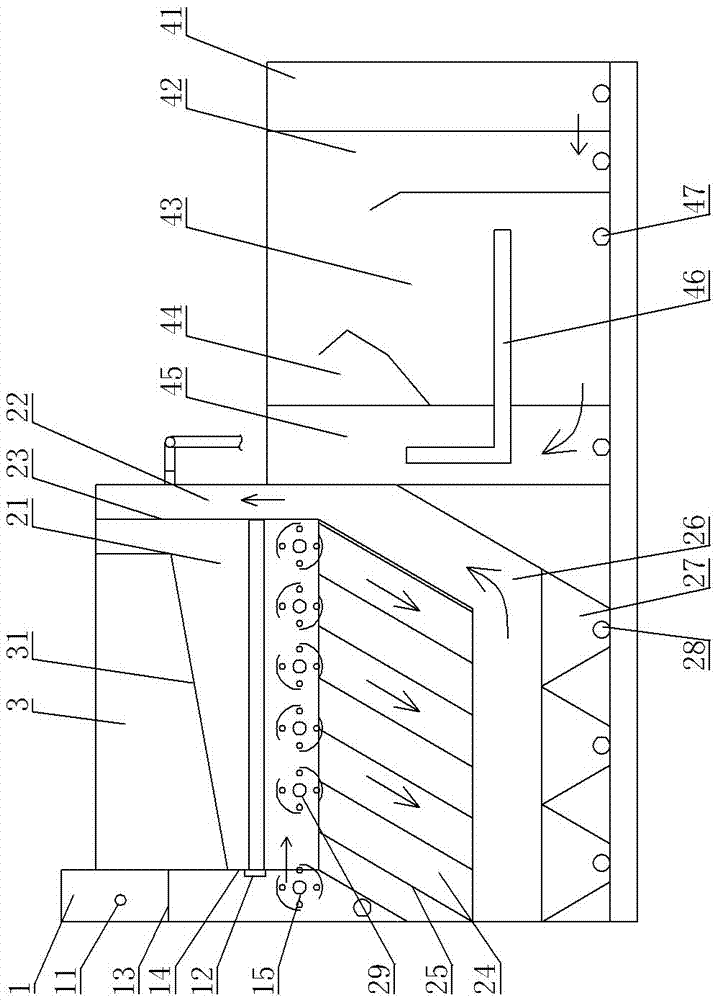

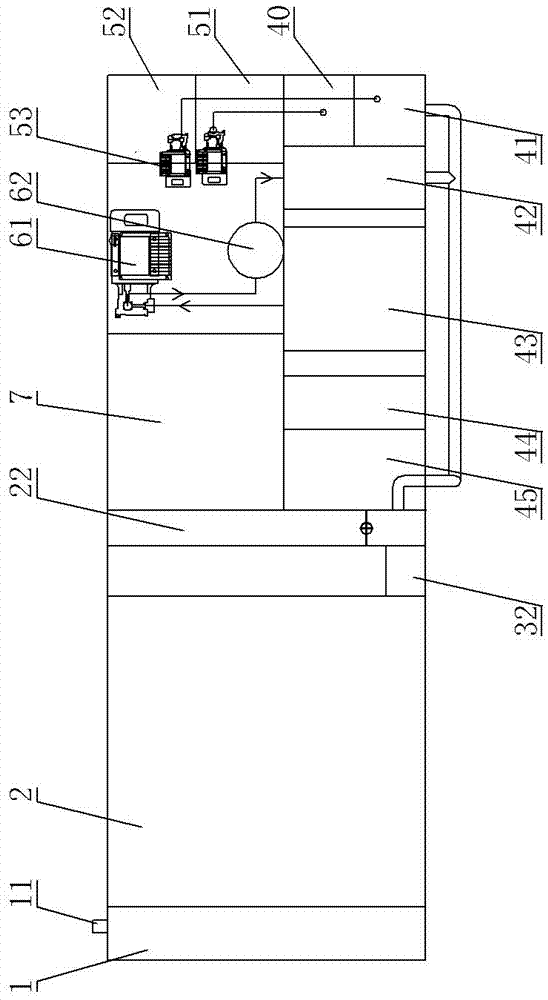

[0015] Such as Figure 1 to Figure 2 As shown, it includes a solid-liquid separation tank 1, an oil trap 21, an air flotation tank, and an adsorption tank 7. The oil trap 21 is connected to a slick oil collection device. The air flotation tank includes a dissolved gas system and sequentially connected dissolving tank, reaction tank, Contact mixing tank 42, separation tank 43 and clean water tank 45. The clean water tank 45 communicates with the adsorption tank 7. The dissolving tank includes a first dissolving tank 51 and a second dissolving tank 52. The reaction tank includes a first reaction tank 40 and a second dissolving tank. The second reaction tank 41, the first dissolving tank 51 is connected to the first reaction tank 40 through a dosing pump and a pipeline, and the second dissolving tank 52 is connected to the second reaction tank 41 through a dosing pump 53 and a pipeline, and the separation tank is provided There is a slag scraper and a slag tank 44 matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com