Environment-friendly rubber asphalt and preparation method thereof

An environmentally friendly rubber and asphalt technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of complex process, high cost of rubber asphalt, strict requirements, etc., to reduce environmental pollution, reduce production costs, and improve high temperature performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

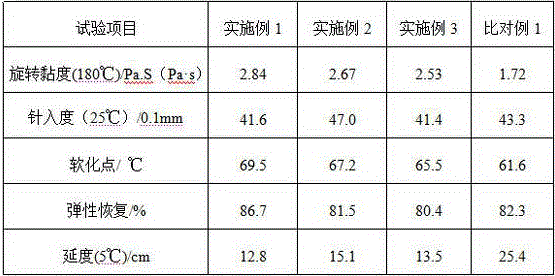

Examples

Embodiment 1

[0032] The environment-friendly rubber modifier provided by the present embodiment comprises components by mass percentage: base asphalt 72%, waste tire rubber powder and modifier 28% (wherein 20 mesh waste tire rubber powder 92%, 2% activator, 2% binder, 2% activator, 1% vulcanizing agent, 1% antioxidant), heat the base asphalt, the heating temperature is 185 °C, after the base asphalt is melted, waste rubber powder and modifier Mix evenly, pour it into the base asphalt, and manually stir for 10 minutes to mix the waste rubber powder and modifier into the base asphalt, use a high-speed shearer, stir at a speed of 1200 rpm for 12 minutes, and then use a 3500 rpm Stir at a speed of 12 minutes, and finally adjust to a speed of 5500 rpm and stir for 25 minutes, and carry out 60 minutes of stability development treatment to obtain environmentally friendly rubber asphalt.

[0033] Among them, the base asphalt is 70# base asphalt, which is better produced in China.

[0034] Waste t...

Embodiment 2

[0041] The environment-friendly rubber modifier provided by the present embodiment comprises components by mass percentage: 75% of matrix asphalt, waste tire rubber powder and 25% of modifier (wherein 40 mesh waste tire rubber powder 88%, 3% activator, 3% binder, 3% activator, 2% vulcanizing agent, 1% antioxidant), heat the base asphalt at 180°C, after the base asphalt is melted, mix waste rubber powder and modifier Mix evenly, pour it into the base asphalt, and manually stir for 10 minutes to mix the waste rubber powder and modifier into the base asphalt, use a high-speed shearer, stir at a speed of 1000 rpm for 15 minutes, and then use a 3000 rpm Stir at a speed of 15 minutes, and finally adjust to a speed of 5000 rpm and stir for 30 minutes, and carry out 80 minutes of stability development treatment to obtain environmentally friendly rubber asphalt.

[0042] Among them, the base asphalt is 90# base asphalt, which is better produced in China.

[0043] Waste tire rubber pow...

Embodiment 3

[0050] The environment-friendly rubber modifier provided by the present embodiment comprises components by mass percentage: base asphalt 78%, waste tire rubber powder and modifier 22% (wherein 40 mesh waste tire rubber powder 82%, 4% activator, 5% binder, 4% activator, 3% vulcanizing agent, 2% antioxidant), heat the base asphalt, the heating temperature is 175 °C, after the base asphalt is melted, waste rubber powder and modifier Mix evenly, pour it into the base asphalt, and manually stir for 10 minutes to mix the waste rubber powder and modifier into the base asphalt, use a high-speed shearer, stir at a speed of 800 rpm for 18 minutes, and then use a 2500 rpm Stir at a speed of 18 minutes, and finally adjust to a speed of 4500 rpm and stir for 35 minutes, and carry out 90 minutes of stability development treatment to obtain a new type of environmentally friendly rubber asphalt.

[0051] Among them, the base asphalt is 50# base asphalt, which is better produced in China.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com