Quick connect conductive device for coating

A fast, conductive connection technology, applied in the direction of electrodes, can solve the problems of difficult conductive connections, and achieve the effects of shortening disassembly time, avoiding pollution, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

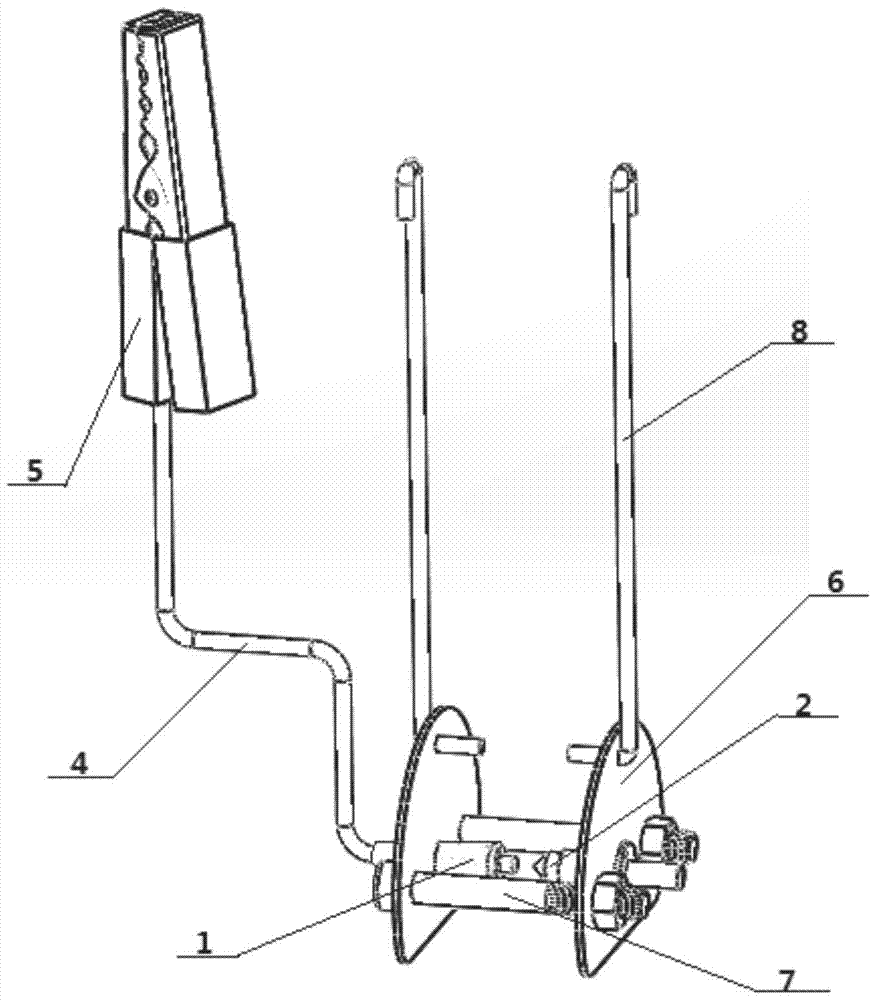

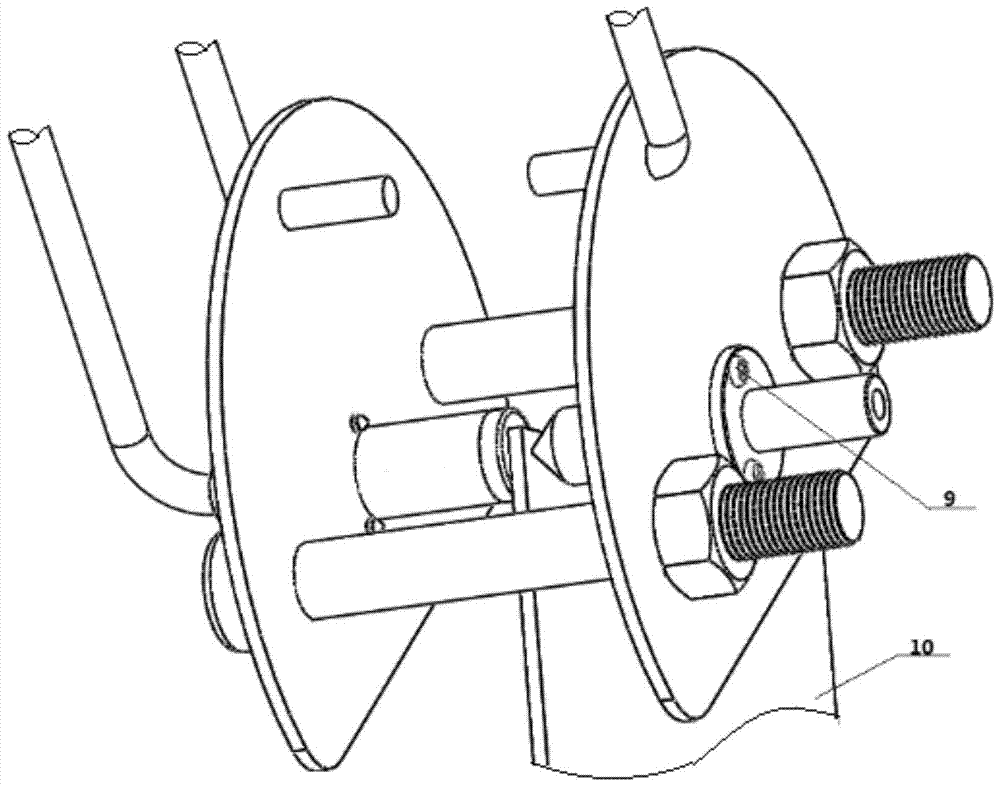

[0017] Embodiment 1: The quick-connect conductive device for coating in this embodiment includes a conductive contact box 1, a fixed insulating contact 2, a wire 3, an insulating tube 4, a connecting clip 5, two support plates 6, and fastening bolts 7 and boom 8;

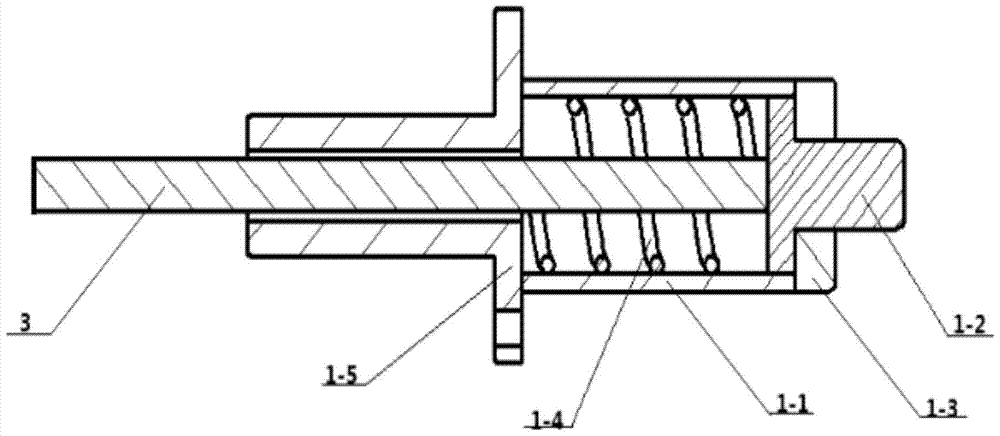

[0018] The conductive contact box includes an insulating shell 1-1, a conductive contact 1-2, an elastic gasket 1-3, an elastic body 1-4, and an insulating rear end cover 1-5; the elastic body 1-4 and the conductive contact 1-2 is arranged in the insulating housing 1-1, the front end of the insulating housing 1-1 is connected with an elastic gasket 1-3, and the contact of the conductive contact 1-2 is exposed through the elastic gasket 1-3. The rear end of the insulating shell 1-1 is connected with an insulating rear end cover 1-5, and the middle part of the insulating rear end cover 1-5 has a hole;

[0019] One end of the wire 3 is connected to the conductive contact 1-2, and the other end passes through the hole ...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the elastic body 1-4 inside the insulating housing 1-1 in the conductive contact box 1 is a compression spring. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the contact of the fixed insulating contact 2 is conical. Others are the same as in the first or second embodiment.

[0023] The shape of the contact in this embodiment makes the contact area between the fixed insulating contact 2 and the sample small, which has little influence on the coating area. At the same time, it can also clamp and fix the sample and have good electrical conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com