Line framework and wire stringing structure

A wire and line technology, which is applied in the field of power transmission and distribution, can solve the problems of increased spacing between cooling towers, increased operating costs, and large footprints, and achieves the effects of reducing investment, reducing operating costs, and large spans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

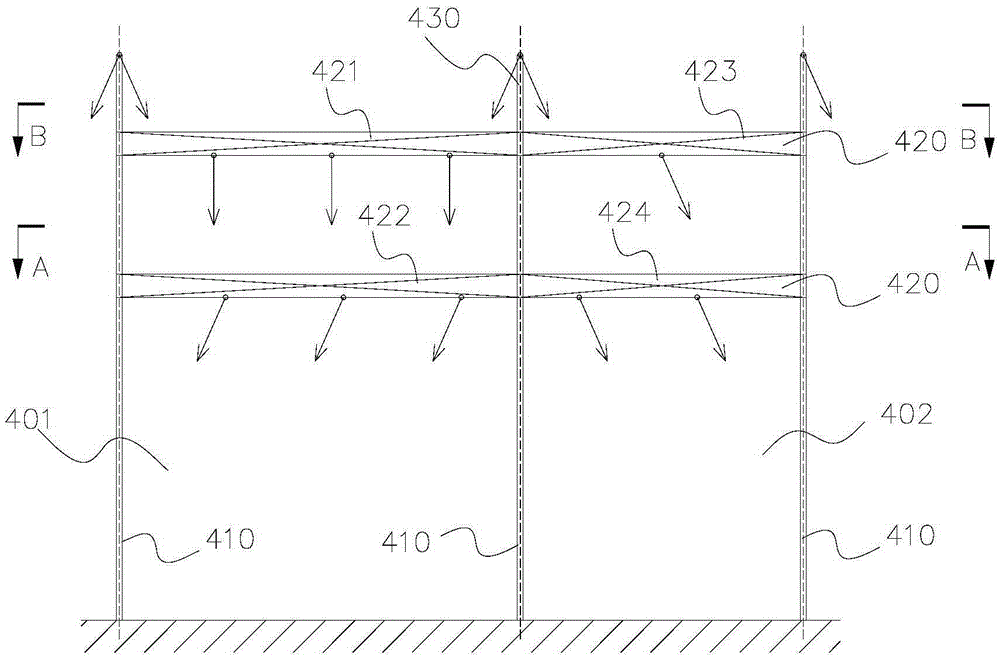

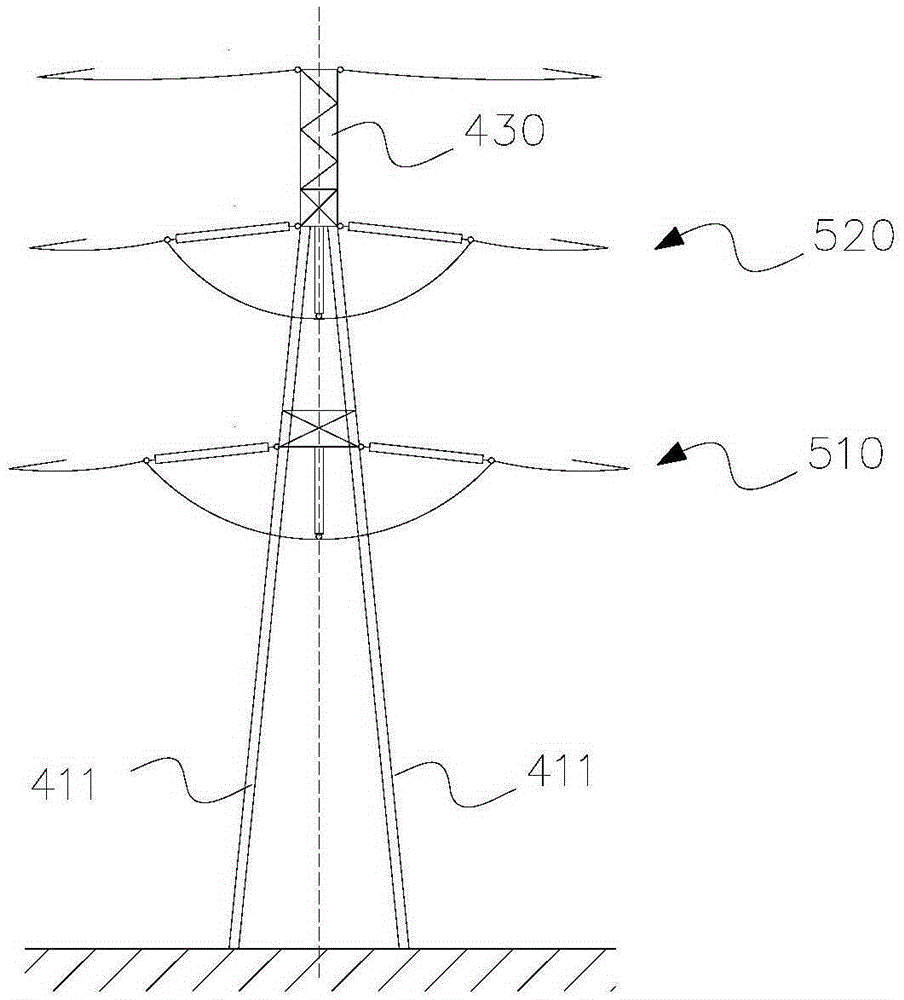

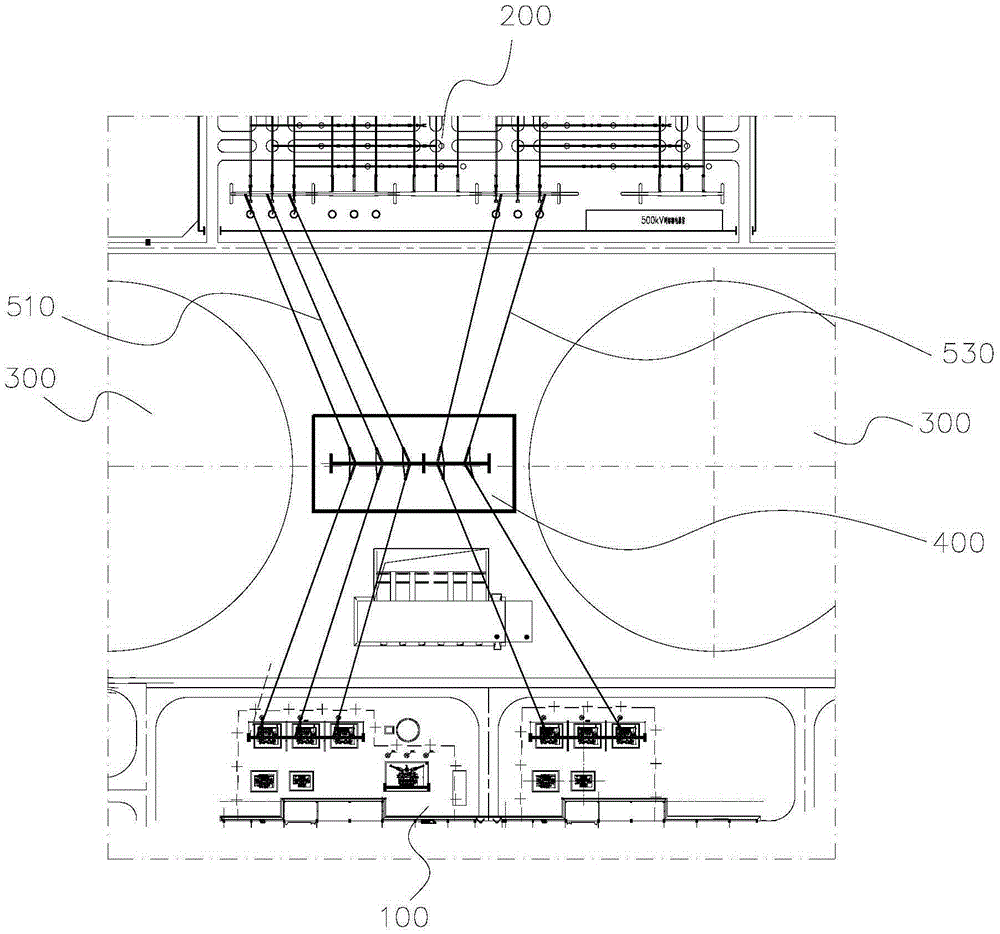

[0023] Such as image 3 , 4 As shown, the wiring structure includes a line frame 400 and three line groups. The line frame 400 is located between the main unit 100 and the booster station 200, and is located between two cooling water towers 300. The three line groups are respectively connected to the main unit. 100 and the lead wire interface of the step-up station 200, each line group has three lead wires.

[0024] Such as figure 1 As shown, the line frame 400 includes a base frame, and the base frame includes two horizontal beams 420 arranged side by side and three pillars 410 arranged horizontally. In the middle part, a first wire channel 401 and a second wire channel 402 are sequentially formed between the pillars 410, and the width of the first wire channel 401 is greater than the width of the second wire channel 402. The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com