Liquid sloshing preventing method of concrete rectangular liquid storage structure

A liquid storage structure and liquid sloshing technology, applied in the field of liquid storage structure, can solve the problems of liquid storage structure cracking, splashing, national and people's economic losses, etc., to reduce the liquid level fluctuation range, avoid cracking or damage, and structural reliability enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

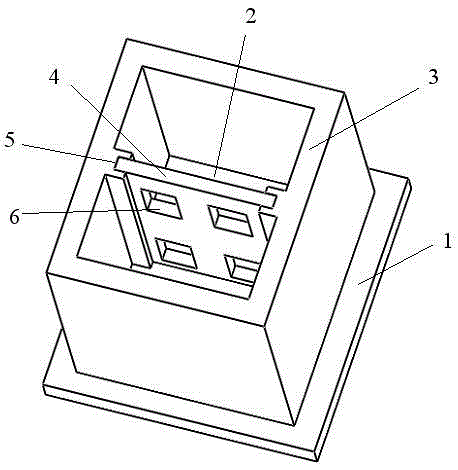

[0024] Such as figure 1 Shown, the present invention is the method that concrete rectangular liquid storage structure prevents liquid from sloshing, and its steps are:

[0025] (1) According to the geotechnical engineering investigation report of the site, determine and carry out foundation treatment;

[0026] (2) Lay the plain concrete cushion 1, support the formwork on the concrete cushion 1, configure the steel bars and set the embedded parts;

[0027] (3) Pouring the bottom plate 2 and wall plate 3 of the rectangular liquid storage structure, and setting a groove 5 with the same thickness as the vertical partition 4 on the inner side of the wall plate 3;

[0028] (4) According to the chemical properties of the liquid in the structure, select materials and make vertical partitions 4, and reserve holes 6 on the vertical partitions 4;

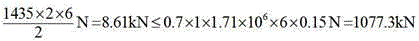

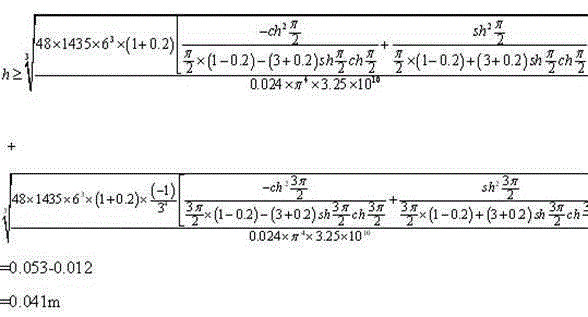

[0029] (5) The thickness h of the vertical partition 4 is determined by formula (a):

[0030] (a)

[0031] The thickness of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com