friction torque converter

A torque converter and friction-type technology, which is applied in friction transmission devices, transmission devices, belts/chains/gears, etc., can solve the problems of reduced machine transmission efficiency, high cost, and headaches for users, and achieves simple structure, low cost, and The effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

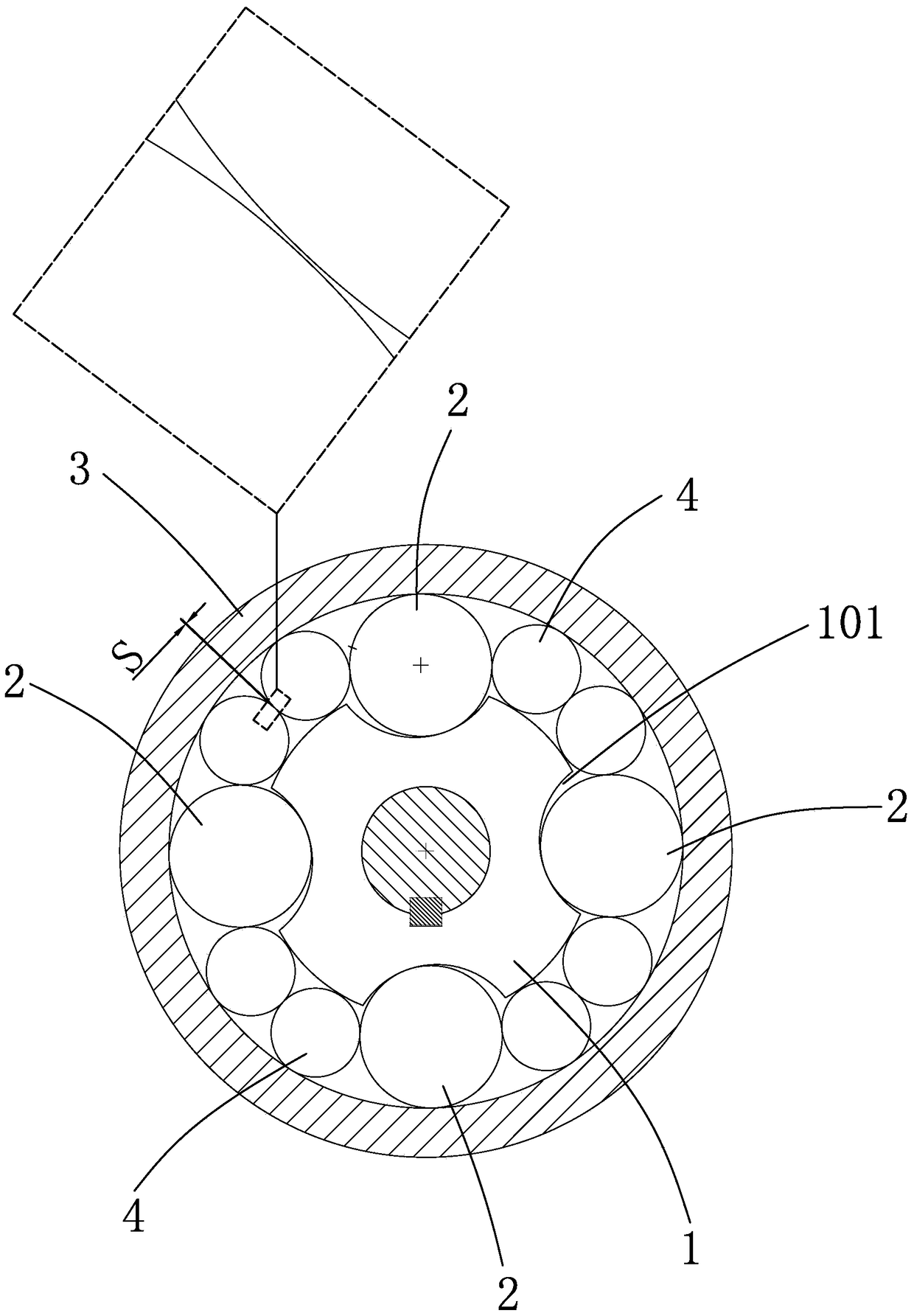

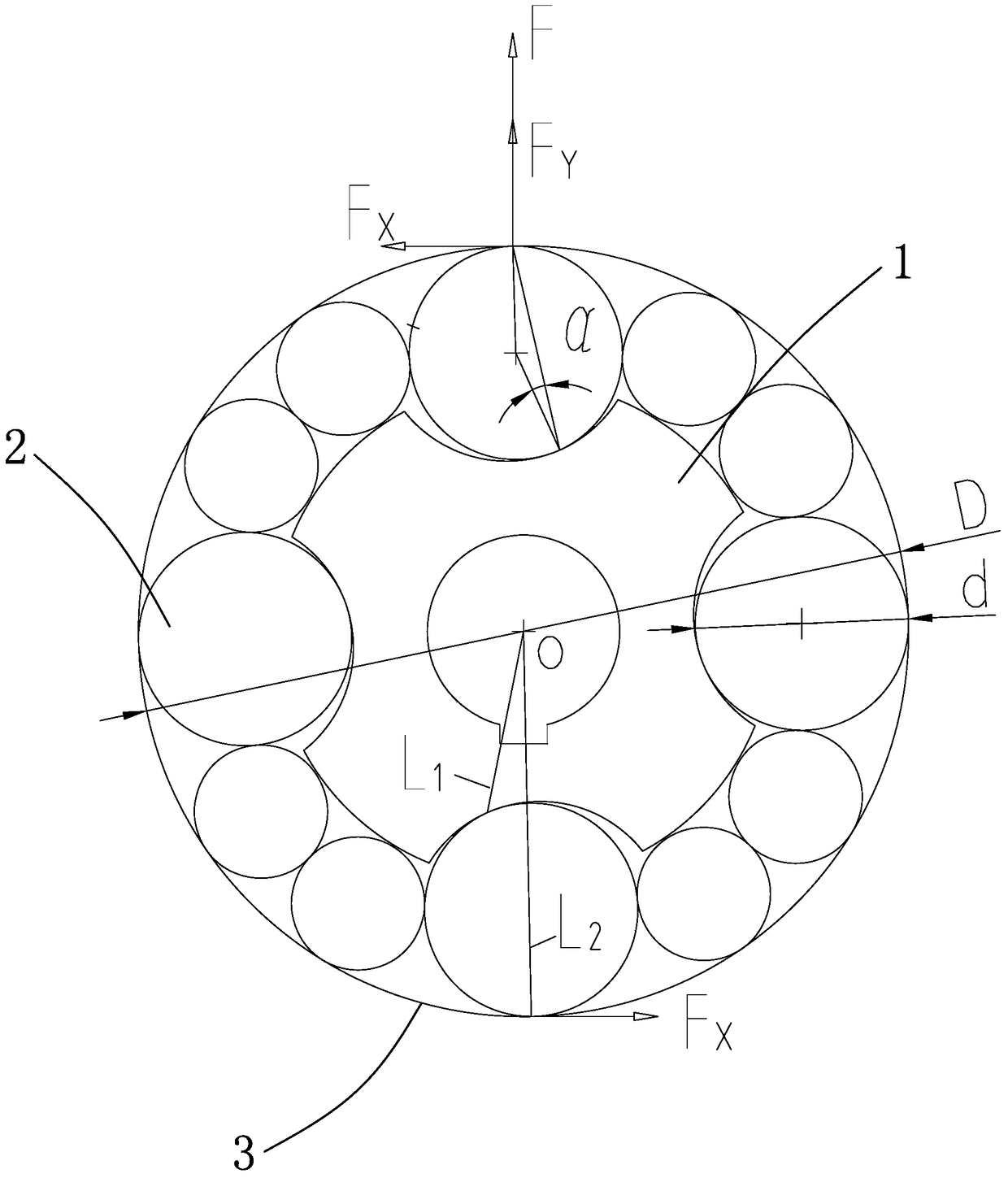

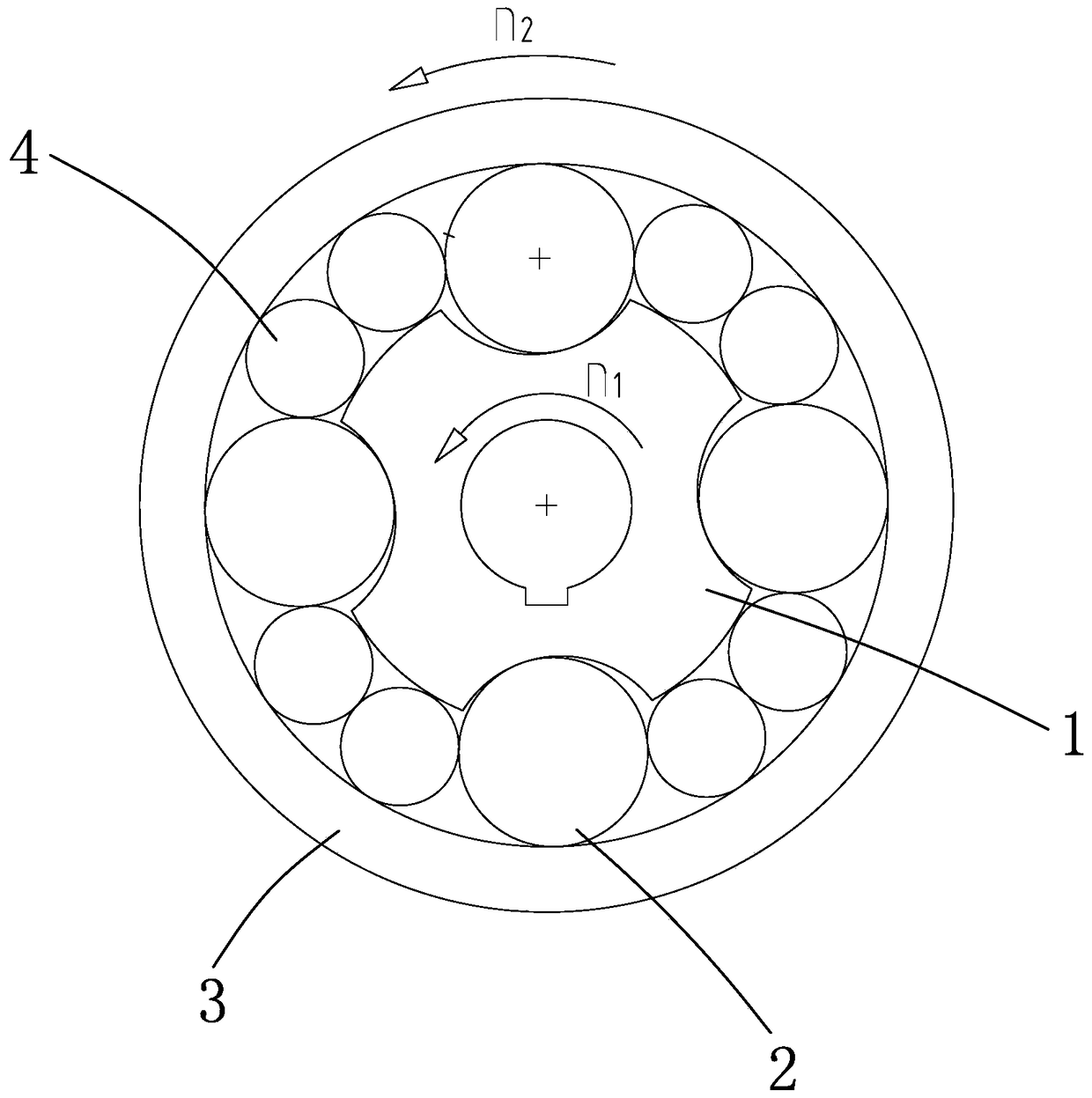

[0046] Example: see Figure 4 , a friction torque converter, including an inner ring 1, a large roller 2 and an outer ring 3, wherein:

[0047] The inner ring 1 is an input unit. At least two concave grooves 101 are evenly distributed on the peripheral side of the inner ring to form an inner ring cam. Each concave groove corresponds to a large roller. Figure 4 3 concave grooves and corresponding large rollers 2 are set in the middle;

[0048] The outer ring 3 is the output unit. The outer ring 3 is set outside the inner ring 1 and arranged coaxially with the inner ring 1. The inner peripheral surface of the outer ring 3 forms the inner raceway of the outer ring and is press-cut with each roller. Here The pressure cut means that the roller surface is pressed against the inner raceway of the outer ring. Since the roller and the outer ring are both arc-shaped surfaces, the two must be tangentially pressed;

[0049] The large roller 2 is arranged between the inner ring and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com