Substation oil-filling equipment oil leakage rate monitoring system

A technology of oil injection equipment and monitoring system, which is applied in the direction of fluid velocity measurement, signal transmission system, velocity/acceleration/shock measurement, etc. It can solve the problems of not being able to effectively track the development trend of leakage in real time and consume a lot of manpower, so as to prevent the expansion of defects , to facilitate the correct judgment of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

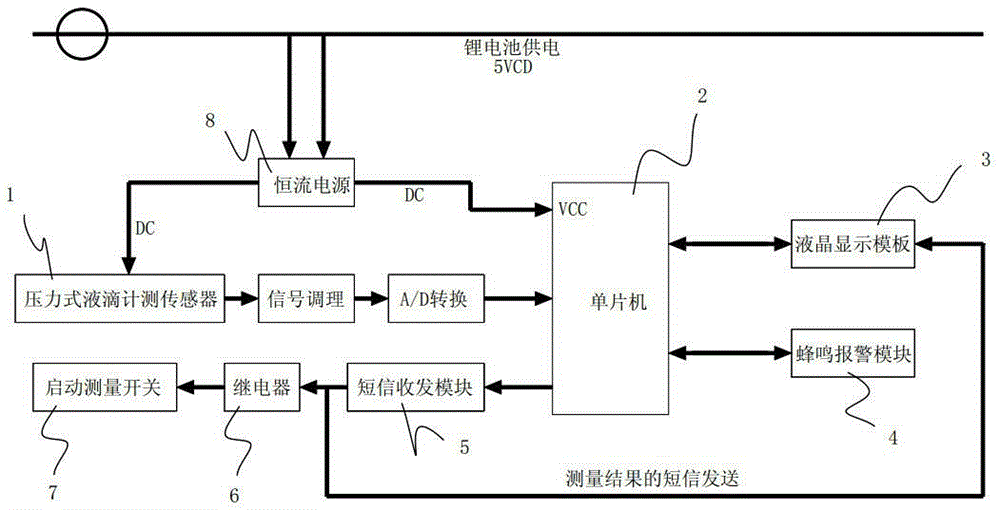

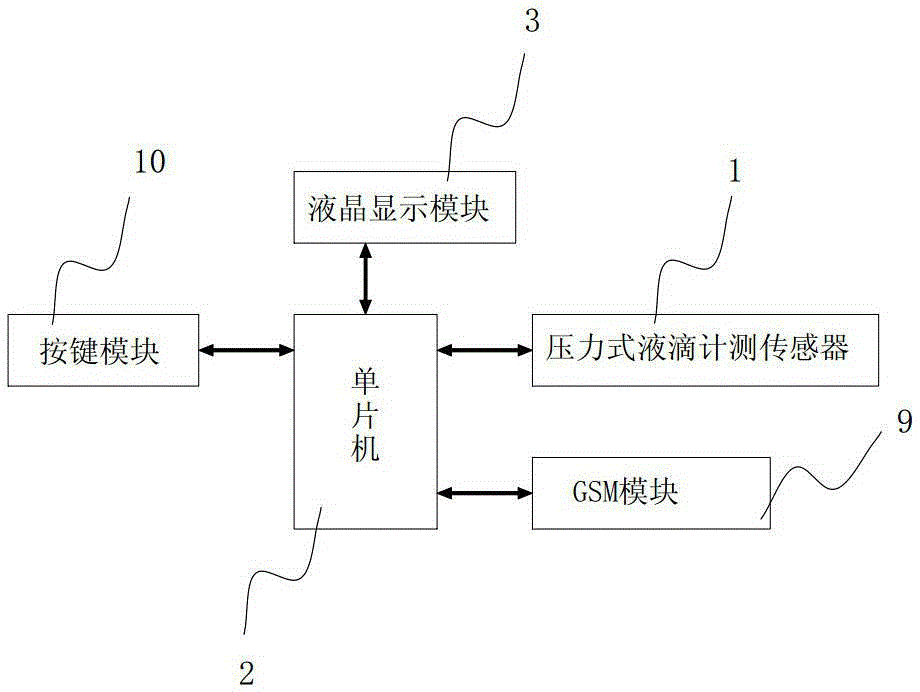

[0017] The oil leakage rate monitoring system of substation oil injection equipment described in Example 1, such as figure 1 and figure 2 As shown, it includes a piezoelectric droplet measurement sensor 1 for detecting the leakage oil droplet area of the oil injection equipment in the substation, and a sensor connected to the piezoelectric droplet measurement sensor and receiving the output signal of the piezoelectric droplet measurement sensor. Single-chip microcomputer 2, liquid crystal display module 3, buzzer alarm module 4, short message transceiver module 5 connected separately with single-chip microcomputer, short message transceiver module is connected with liquid crystal display module, short message transceiver module is connected with relay 6, and relay is connected with start measurement switch 7; The piezoelectric drop measurement sensor and the single-chip microcomputer described above are all connected with a constant current power supply 8 powered by a lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com