Method for calculating allowed highest temperature in circular section lining concrete construction period

A technology of maximum temperature and calculation method, applied in calculation, hydraulic engineering, hydraulic engineering equipment, etc., can solve problems such as no reasonable available method, no clear requirement for crack resistance safety factor, and inability to effectively achieve temperature crack control goals, etc. achieve high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Take the temperature control and anti-cracking of the concrete lining of the circular section of the flood discharge tunnel of a hydropower station as an example.

[0048] 1. Basic information

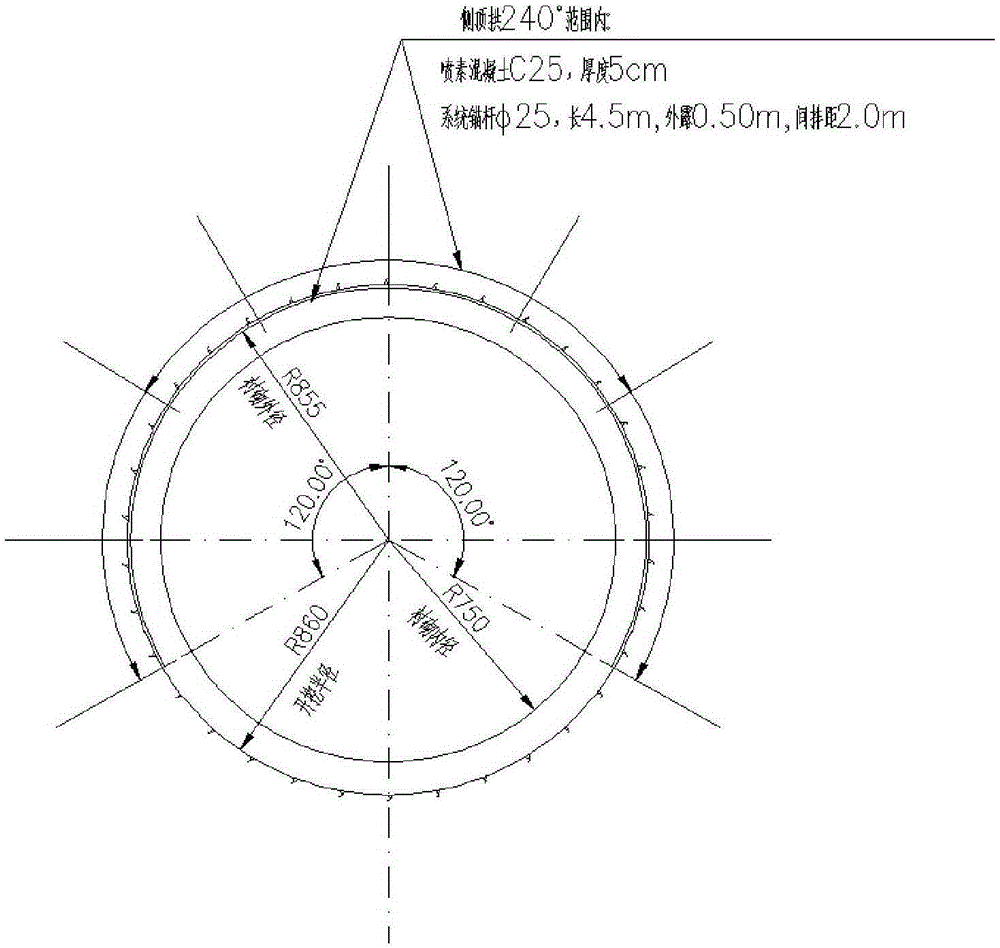

[0049] A hydropower station is a large (I) project, the spillway is the main building (level I), and the pressure section is a circular section. The types of lining and surrounding rock are listed in Table 1. The inner diameter of the lining section is 7.5m (such as figure 1 shown), the design strength level of lining concrete is C 90 40. The length of the joint in the structural section is 9m. According to the measured data in the cave at the initial stage of excavation and the data provided by the design institute, the design unit takes the average temperature for many years as 23.5°C and the annual temperature variation as 1.5°C, and calculates with the cosine formula (10) according to the code.

[0050] T a = ...

Embodiment 2

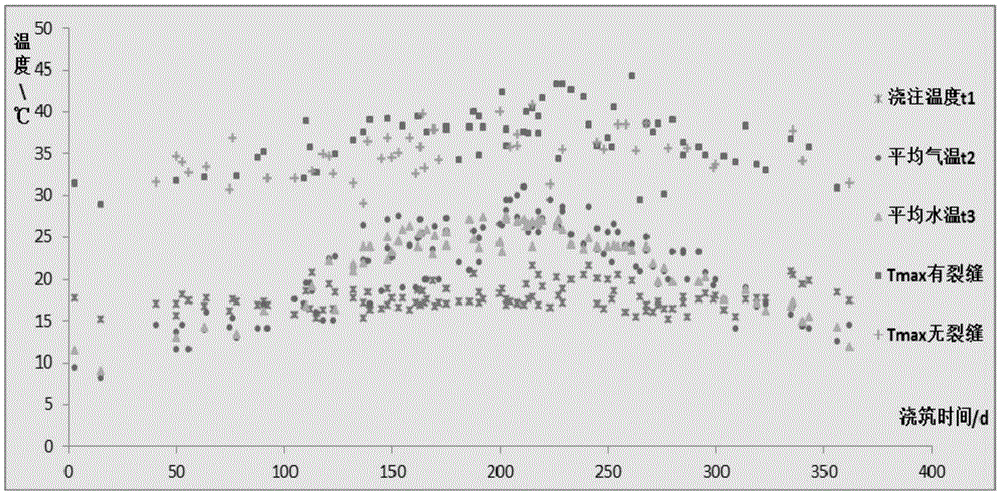

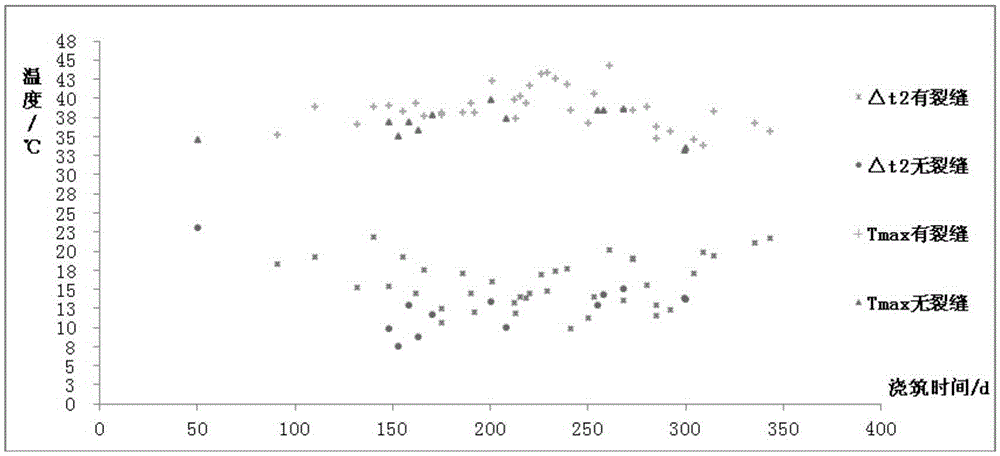

[0101] Example 2: The maximum allowable temperature during the construction period of the concrete lining of the hydraulic tunnel of Wudongde Hydropower Station

[0102] The Survey and Design Institute of the Yangtze River Committee adopts the allowable temperature difference of the dam foundation concrete for the temperature control and crack prevention of the hydraulic tunnels (including power generation tunnels, diversion tunnels, and flood discharge tunnels) of the Wudongde Hydropower Station, referring to the "Code for Design of Concrete Arch Dams" ( DL / T5346-2006), since the concrete degree of the lining of the spillway tunnel is the standard design of the strong confinement area, the allowable temperature difference is added as the maximum temperature on the basis of the monthly average temperature in the tunnel (because it is the construction period, this is the monthly stable temperature field) control value. Firstly, according to the different operating conditions of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deformation modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com