A Multiple Defect Detection Method Based on Image Block Variance-Weighted Eigenvalues

A technology of weighted eigenvalues and image segmentation, which is applied in the field of multi-defect detection, can solve the problems of difficulty in online detection, difficult to meet production efficiency, easy to fatigue, etc., achieves low detection rate of missed detection and false detection, and has self-adaptive ability. , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

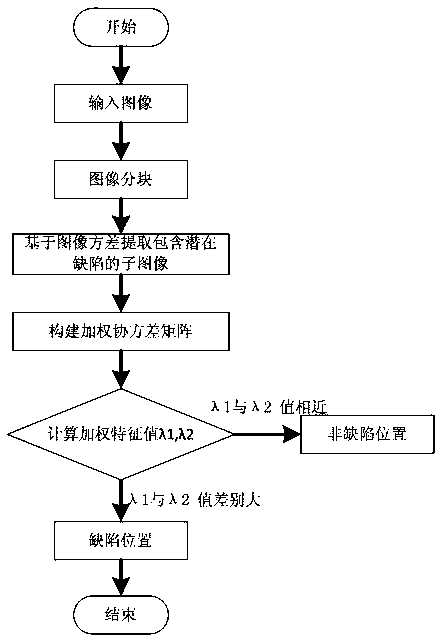

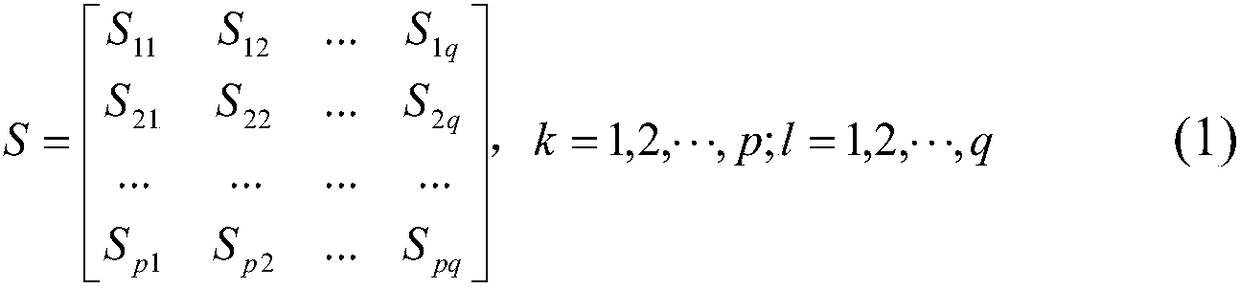

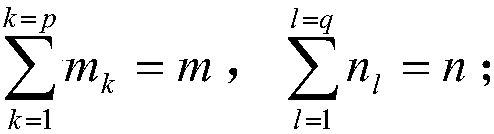

[0047] The invention adopts the multi-defect online detection method based on image block variance-weighted characteristic value, which is an improved and comprehensive method. Its purpose is to detect all defect targets in the image at the same time. This method first divides the preprocessed image into blocks, and extracts the potential defect position sub-image by comparing the variance of the image with the variance of the block sub-image; then performs weighting processing on the defect sub-image to construct a multidimensional weighted covariance matrix, Calculate the eigenvalue of the weighted covariance matrix, and finally determine the weighted eigenvalue λ 1 ,λ 2 The value of determines whether the subimage contains defects:

[0048] Step1: If the weighted eigenvalue λ 1 ,λ 2 If the value of is similar, there is no defect in the sub-image block;

[0049] Step2: If the weighted eigenvalue λ 1 Much larger than the weighted eigenvalue λ 2 , then there is a defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com